Optimizing Thermal Baseline Experiments with Heating Wire Assistance for Faster Acquisition of Battery Heat Characteristics

Key Points Review – Thermal Baseline

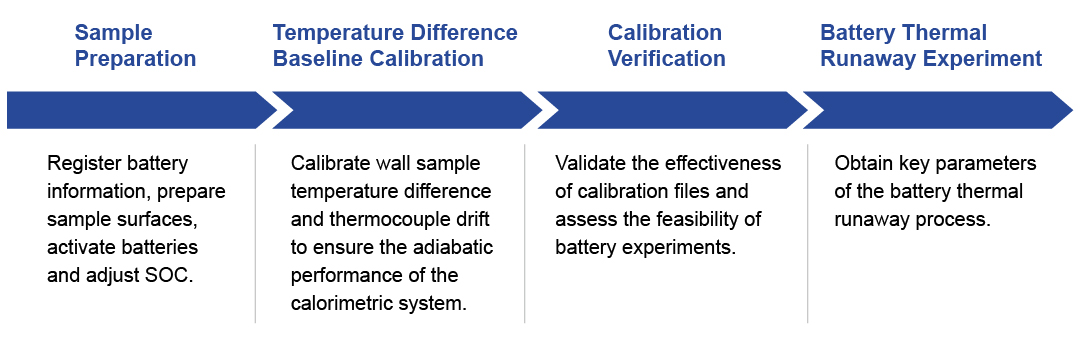

The battery adiabatic calorimeter is the main instrument for testing the adiabatic thermal runaway characteristics of lithium batteries. To obtain the most accurate and effective test data, the complete testing process includes four steps: sample preparation, temperature difference baseline calibration, calibration validation, and battery testing. Among them, temperature difference baseline calibration can ensure the adiabatic performance of the instrument and is an important operational step to improve the detection sensitivity and accuracy of the instrument.

Under normal usage conditions, temperature baseline calibration is typically conducted every two months. The necessity of repeating the calibration mainly arises from two aspects:

- Long-term exposure to high temperatures can gradually cause temperature drift in the temperature-measuring thermocouples.

- Significant variations in the temperature field inside the calorimeter chamber occur due to large differences in the dimensions of the samples.

Additionally, if there are replacements of zero components such as temperature sensors or insulation cotton, the temperature difference baseline calibration experiment needs to be conducted again.

The duration of the calibration experiment is related to the quality of the sample. For large cells such as 280Ah lithium iron phosphate cells, the required time is longer, possibly taking 3-5 days or even more than a week, greatly delaying the progress of the experiment. Based on the aforementioned issues, this article proposes a temperature difference baseline experimental scheme assisted by heated wire. The scheme involves wrapping the sample’s surface with a heated wire and using it to heat the sample, thereby shortening the sample’s heating time and significantly reducing the duration of the temperature difference baseline experiment, thus improving experimental efficiency significantly.

Experimental Section

1. Sample Preparation

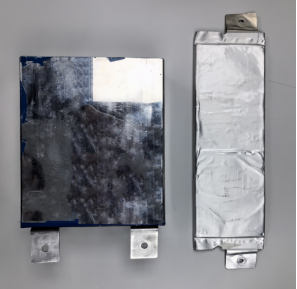

This article processed standard aluminum block samples required for experiments according to the dimensions of two typical cell samples.

#1 Aluminum Block: 20417353mm, 5625g; #2 Aluminum Block: 27410412mm, 924g.

Figure 1: Selected typical cell samples

2. Experimental Procedure

(1) Conventional Temperature Difference Baseline Experiment:

Select the “Temperature Difference Baseline” mode and conduct the temperature difference baseline experiment following conventional experimental procedures.

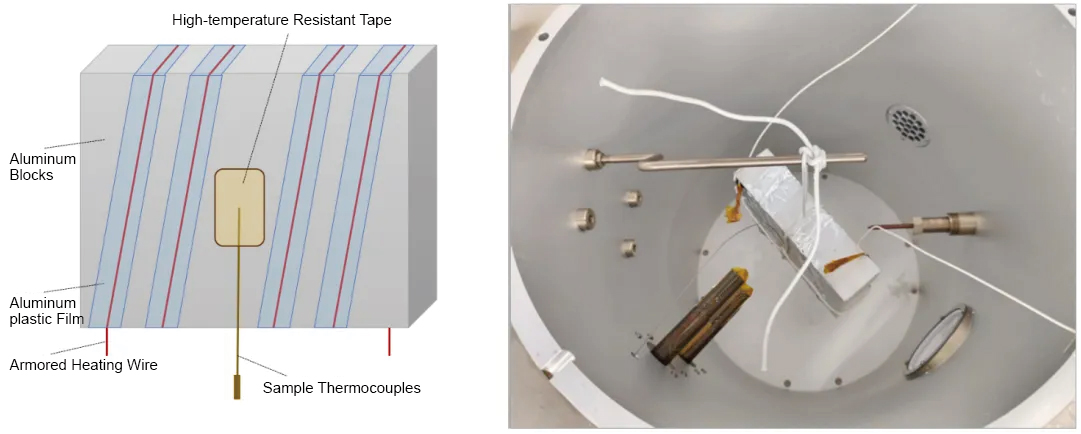

(2) Heated Wire-Assisted Heating Temperature Difference Baseline Experiment:

Select the “Temperature Difference Baseline” mode and wrap the sample with a heated wire. Connect it to an external power source for auxiliary heating. All other experimental procedures remain consistent with the conventional temperature difference baseline experiment.

(3) Calibration File Validation:

Select the “HWS” mode and perform the aluminum block HWS stepwise heating experiment. Calculate the temperature rise rate of each step of the sample and validate the effectiveness of the calibration file.

Figure 2: Schematic diagram and actual photo of sample preparation/loading (high-temperature resistant tape, sample thermocouples, aluminum blocks, aluminum-plastic film, armored heating wire).

Experimental Results

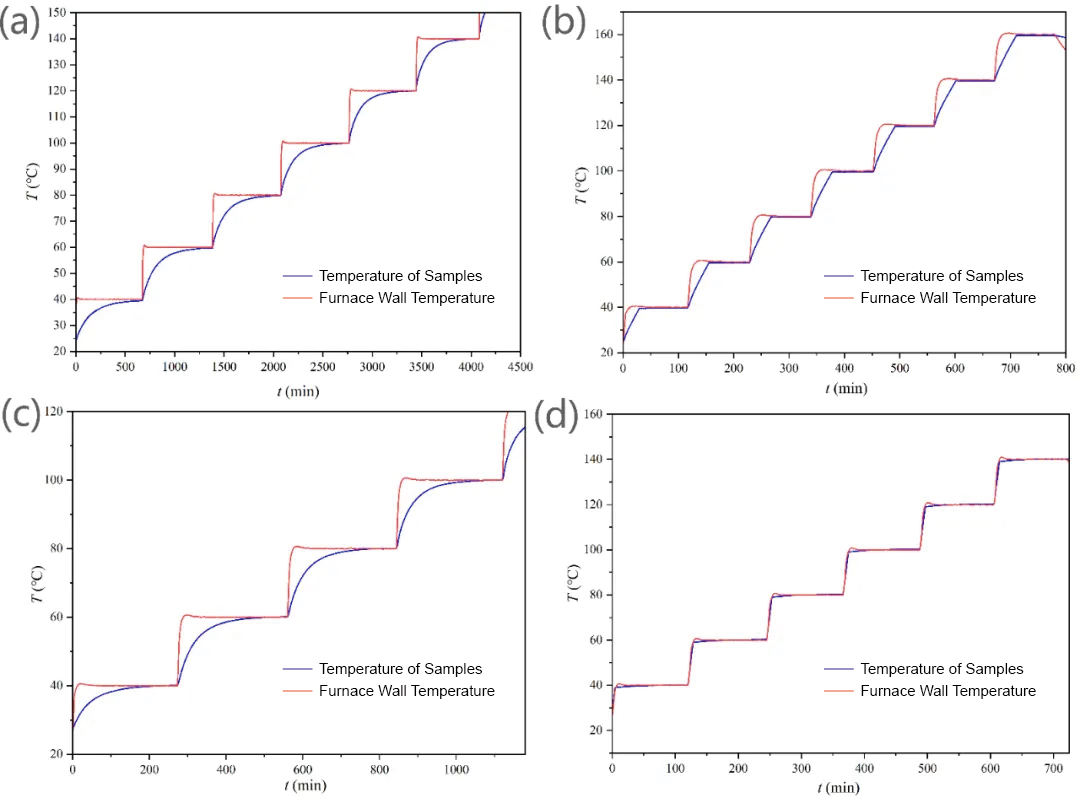

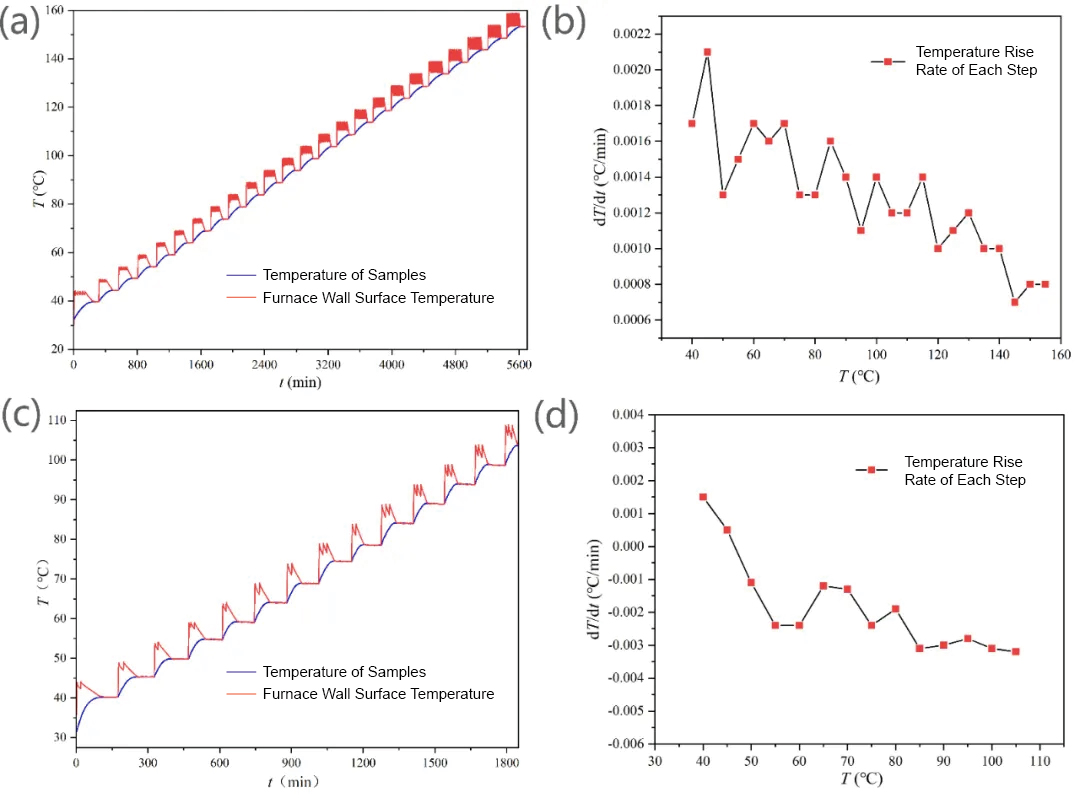

As shown in Figure 3, comparing the temperature rise curves obtained from the two types of temperature difference baseline experiments, it can be observed that in the conventional experimental mode, the sample heats up slowly inside the calorimeter chamber through convection, conduction, etc., and the heating stage occupies the majority of the experimental time. However, by using the heated wire for auxiliary heating, it forcibly increases the sample’s temperature rise rate.

Figure 3: Comparison of temperature rise curves for conventional temperature difference baseline (a, c) and heated wire-assisted heating temperature difference baseline (b, d) experiments for samples #1 (a, b) and #2 (c, d).

According to Table 1, after optimization, the single-step time for samples #1 and #2 is only 15.8% and 41.4% of the original time, respectively. The improvement is particularly significant for samples with large masses. After optimization, the single-step duration for both samples is between 110 minutes and 120 minutes, while a typical temperature difference baseline experiment requires running 6 to 10 steps. Therefore, most samples can be tested within one day, significantly improving the efficiency of the temperature difference baseline experiment.

|

Sample Name |

Duration of a single step in the conventional temperature difference baseline (min) |

Duration of a single step in the optimized temperature difference baseline (min) |

Comparison of single-step time ratio |

|

#1 |

710 |

112 |

15.8% |

|

#2 |

285 |

118 |

41.4% |

Table 1: Comparison of Test Durations for Two Types of Temperature Difference Baseline Experiments

Subsequently, the effectiveness of the calibration file obtained through the heated wire-assisted heating scheme was validated using the HWS mode. As shown in Figure 4, the temperature rise rates for each temperature step of the HWS temperature rise curve are within the effective range of -0.005 to 0.005°C/min. After calibration, the instrument’s adiabatic performance is good, demonstrating that this optimization scheme improves experimental efficiency without sacrificing calibration accuracy.

Figure 4: Verification of the calibration results for heated wire-assisted heating temperature difference baseline for samples #1 (a, b) and #2 (c, d).

Exploring Battery Safety with the BAC-420A Large Battery Adiabatic Calorimeter – Thermal Baseline

- Simulated Adiabatic Environment: The BAC-420A replicates an ideal adiabatic environment, enabling direct measurement of critical thermal behavior parameters such as thermal runaway onset temperature, maximum temperature rise rate, and adiabatic temperature rise. This simulation ensures more accurate and reliable results, crucial for assessing battery safety.

- Comprehensive Data Acquisition:Equipped with capabilities for simultaneous data acquisition of battery voltage, current, temperature, and pressure, the BAC-420A facilitates thorough thermal runaway analysis. By capturing multiple parameters in real-time, it provides a holistic understanding of battery performance under various conditions.

- Integrated Charging and Discharging Module:The inclusion of a charging and discharging module allows for seamless mode switching, adjustable charge/discharge currents, and real-time capacity calculations. This integration streamlines testing procedures and enhances the efficiency of data collection, contributing to more precise evaluations.

- Advanced Testing Modes:With constant power and constant rate specific heat test modes, the BAC-420A offers versatility in assessing battery specific heat capacity. Its unique testing process ensures accurate measurements, essential for understanding the thermal properties of batteries.

Conclusion

The heated wire-assisted heating temperature difference baseline experimental scheme significantly improves experimental efficiency, especially with noticeable optimization effects for samples with large masses. It can reduce the time and concerns associated with calibration for users.