Thermal Abuse Testing: What You Need to Know

Thermal abuse testing is an essential process used to evaluate the safety and reliability of batteries. It involves subjecting batteries to extreme temperatures to determine their ability to withstand abuse such as overheating, overcharging, and short circuits. Thermal abuse testing is critical in ensuring that batteries are safe for use and do not pose any risk of fire or explosion.

During thermal abuse testing, batteries are subjected to high temperatures that can cause thermal runaway, a process where the battery overheats and releases energy that can cause a fire or explosion. The test is designed to simulate real-world conditions, and the results are used to determine the battery’s thermal stability and tolerance. The data collected during the test is used to identify potential safety issues and make improvements to the battery’s design and performance.

Thermal abuse testing is an essential process that ensures the safety and reliability of batteries. It is a critical step in the development and production of batteries used in various applications, including electric vehicles, consumer electronics, and renewable energy systems. The test provides valuable data that is used to identify potential safety issues and make improvements to the battery’s design and performance. With the increasing demand for batteries, thermal abuse testing is becoming more critical than ever to ensure the safety of users and prevent accidents.

Fundamentals of Thermal Abuse Testing

Thermal abuse testing is a crucial aspect of battery safety testing. It involves exposing a battery to extreme temperatures to test its safety performance. The goal is to evaluate how the battery responds to abuse conditions, including electrical, mechanical, and thermal abuse. The information obtained from the test is used to improve battery design and safety.

During the test, the battery is heated to a specific temperature at a specific rate, typically 5°C/min, and held at that temperature for a specified duration. The most common thermal abuse test is the hot-oven test, which is performed by heating the cell in a gravity convection or circulating air oven.

The temperature and duration of the test vary depending on the application and type of battery being tested. For example, the USABC Abuse Test Manual recommends heating a multi-cell lithium-ion pouch battery to 250°C or until failure, whichever comes first.

Thermal abuse testing is essential because it simulates real-world scenarios where batteries may be exposed to extreme temperatures. The test helps to identify potential safety hazards associated with battery failure, such as gas emissions, fires, and explosions.

In conclusion, thermal abuse testing is a fundamental aspect of battery safety testing. It involves exposing a battery to extreme temperatures to evaluate its safety performance. The information obtained from the test is used to improve battery design and safety.

Thermal Abuse Test Procedures

Standard Test Methods

Thermal abuse testing is an integral part of the safety testing of rechargeable energy storage systems (RESSs). The test involves exposing the battery cells to high temperatures to determine their thermal stability. The test is conducted according to standard test methods such as the FreedomCAR Electrical Energy Storage System Abuse Test Manual for Electric and Hybrid Electric Vehicle Applications (SAND2005-3123) and the USABC Abuse Test Manual.

Sample Preparation

To conduct a thermal abuse test, the battery cells must be prepared properly. The cells are first charged to their maximum capacity and then conditioned to a specific temperature to stabilize them. The cells are then heated at a specific rate to a predetermined temperature, typically between 150°C and 250°C, to initiate thermal runaway.

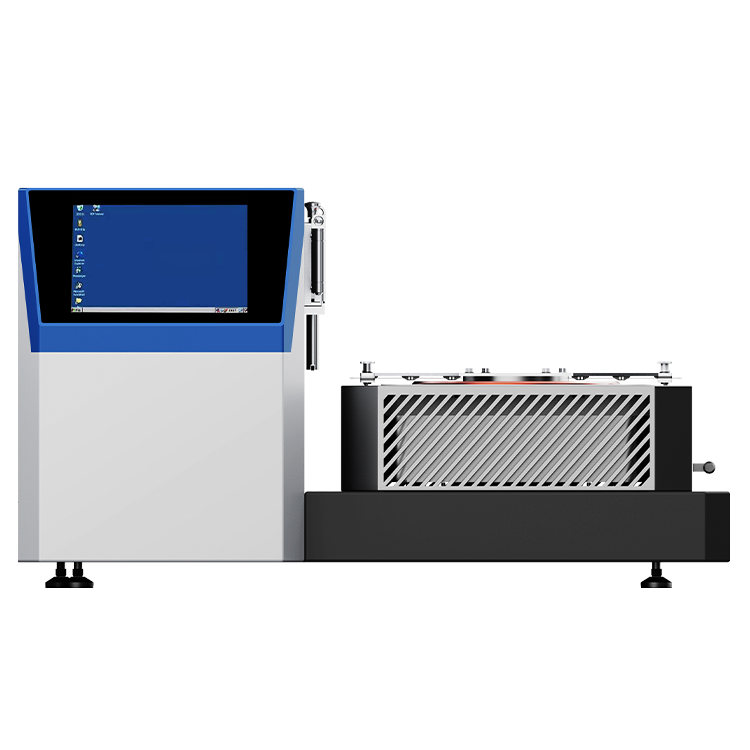

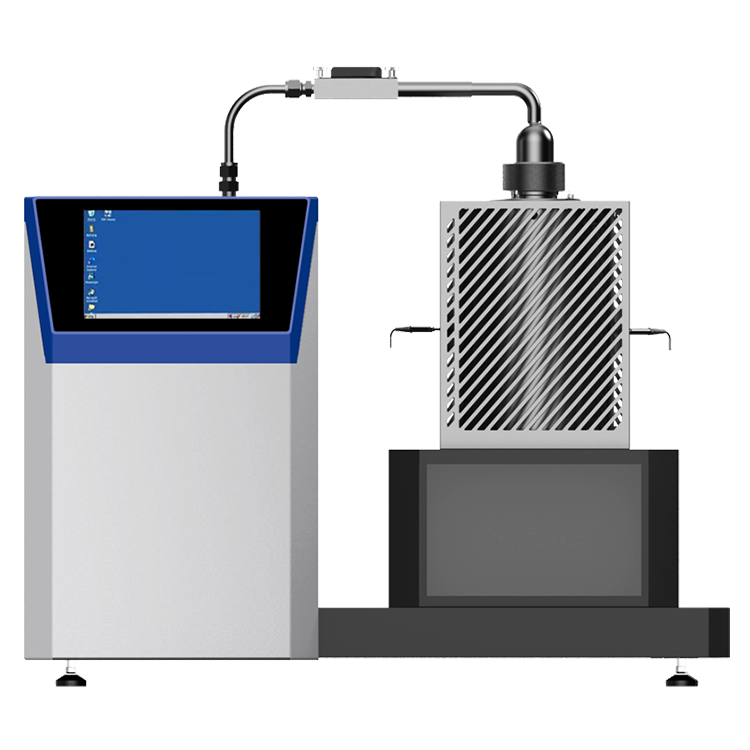

Equipment Setup

The equipment used for thermal abuse testing must be properly set up to ensure accurate and reliable results. The test equipment should be capable of monitoring the temperature of the cells and the pressure inside the test chamber. It should also be equipped with a safety system that can shut down the test if any anomalies are detected.

In conclusion, thermal abuse testing is an essential part of the safety testing of rechargeable energy storage systems. The standard test methods, sample preparation, and equipment setup must be followed to ensure accurate and reliable results.

Safety Considerations in Thermal Abuse Testing

When conducting thermal abuse testing, it is important to prioritize safety to prevent potential harm to yourself or others. Here are some key safety considerations to keep in mind:

Protective Gear

Wear appropriate protective gear such as gloves, safety glasses, and a lab coat to prevent burns and exposure to hazardous materials. Additionally, make sure to wear fire-resistant clothing to protect against potential fires.

Proper Ventilation

Set up your testing area in a well-ventilated space to prevent the buildup of toxic gases. Proper ventilation will also help dissipate heat and reduce the risk of fire.

Fire Suppression Equipment

Have fire suppression equipment such as a fire extinguisher or a fire blanket nearby in case of a fire. Make sure you know how to use the equipment before starting the test.

Test Chamber

Conduct your thermal abuse testing in a test chamber to contain any potential explosions or fires. The test chamber should be made of materials that can withstand high temperatures and pressure.

Test Procedure

Follow the test procedure carefully to ensure accurate and reliable results. Deviating from the procedure can lead to unexpected results or dangerous situations.

By taking these safety considerations into account, you can conduct thermal abuse testing safely and effectively. Remember to prioritize safety at all times to prevent potential harm to yourself and others.

Data Analysis and Interpretation

When conducting thermal abuse testing on lithium-ion batteries, it is critical to monitor and interpret the data collected during the test. The following subsections will discuss the key parameters that should be monitored during thermal abuse testing, including temperature, pressure, and failure mode analysis.

Temperature Monitoring

Temperature monitoring is a crucial aspect of thermal abuse testing. During testing, it is essential to monitor the temperature of the battery to determine when the battery reaches its thermal runaway temperature. This temperature is the point at which the battery begins to self-heat and generate heat at an increasing rate, leading to an uncontrollable release of energy. Typically, the temperature is measured using a thermocouple or infrared camera.

Pressure Measurement

Pressure measurement is another important parameter to monitor during thermal abuse testing. As the temperature of the battery increases, the pressure inside the battery also increases. This pressure can cause the battery to vent, rupture or explode, releasing hazardous gases and materials. Pressure measurements can be taken using pressure transducers or pressure sensors.

Failure Mode Analysis

Failure mode analysis is the process of analyzing the failure modes of a battery during thermal abuse testing. This analysis can help identify the root cause of the failure and provide insights into the design and manufacturing of the battery. Common failure modes during thermal abuse testing include thermal runaway, venting, and explosion. By analyzing the failure modes, you can identify the specific conditions that led to the failure and develop strategies to prevent similar failures in the future.

In conclusion, thermal abuse testing is a critical component of battery safety testing. By monitoring and interpreting the data collected during testing, you can identify potential hazards and develop strategies to mitigate them. Temperature monitoring, pressure measurement, and failure mode analysis are all essential parameters to monitor during thermal abuse testing.

Case Studies and Applications

Thermal abuse testing is a crucial step in the development and manufacturing of lithium-ion batteries. By simulating extreme conditions, manufacturers can identify potential safety hazards and improve the design of their batteries. Here are some examples of how thermal abuse testing has been used in real-world applications.

Electric Vehicles

Electric vehicles rely heavily on lithium-ion batteries to power their engines. However, these batteries are susceptible to overheating and catching fire, which can be dangerous for drivers and passengers. To address this issue, manufacturers use thermal abuse testing to ensure that their batteries can withstand extreme temperatures and remain safe in the event of a crash or other accident.

Consumer Electronics

Lithium-ion batteries are also used in a wide range of consumer electronics, including smartphones, laptops, and tablets. These devices are often subject to rough handling and extreme temperatures, which can cause the batteries to malfunction or even explode. By subjecting their batteries to thermal abuse testing, manufacturers can ensure that their products are safe and reliable.

Aerospace

Lithium-ion batteries are also used in aerospace applications, such as satellites and spacecraft. These batteries must be able to withstand extreme temperatures and radiation, as well as the harsh conditions of space travel. Thermal abuse testing is a critical step in ensuring that these batteries are up to the task and can perform reliably in the harshest of environments.

Overall, thermal abuse testing is a vital tool in the development and manufacturing of lithium-ion batteries. By subjecting batteries to extreme conditions, manufacturers can identify potential safety hazards and improve the design of their products. As a result, consumers can be confident that the batteries in their devices are safe, reliable, and up to the task.

Regulations and Standards Compliance

When it comes to thermal abuse testing of lithium-ion batteries, compliance with regulations and standards is crucial. These regulations and standards are established to ensure the safety of lithium-ion batteries and to prevent accidents caused by thermal runaway.

The safety tests described in international, national, and regional standards typically include abuse testing of lithium-ion batteries for automotive applications. These tests evaluate the battery’s behavior under various conditions, such as overcharge, forced discharge, thermal heating, and vibration.

It is important to note that navigating certification requirements for your diverse target markets can be challenging. UL Solutions offers services to test and certify EV battery cells, modules, and packs for compliance with standards and requirements established across many regions, including North America, Europe, and Asia.

In addition, identifying the temperatures at which key events occur, such as CID activation, venting, and thermal runaway, and identifying the related emissions is essential to defining the hazards to which people, and especially rescue teams, are exposed. For example, a study by MDPI identified key events and emissions during thermal abuse testing of lithium-ion batteries.

Overall, compliance with regulations and standards is essential to ensure the safety of lithium-ion batteries and to prevent accidents caused by thermal runaway.