Dust Explosion Screening Testing: Importance and Procedure

If you work in an industry that deals with powders or dust, you may be aware of the risk of combustible dust explosions. These types of explosions can cause serious damage to equipment, property, and even human life. That’s why it’s important to conduct dust explosion screening testing to assess the risk of dust explosions and take necessary precautions to prevent them.

Dust explosion screening testing involves a series of tests to determine the explosibility of dust and powders. These tests can help identify the hazards associated with different types of dust and powders, and provide information on how to manage or eliminate those hazards. Some of the tests involved in dust explosion screening include the Combustible Dust Screening Test, the Minimum Ignition Energy (MIE) Test, and the Minimum Explosible Concentration (MEC) Test.

By conducting dust explosion screening testing, you can gain a better understanding of the risks associated with dust and powders in your workplace. This knowledge can help you take necessary precautions to prevent dust explosions and ensure the safety of your employees and equipment.

Fundamentals of Dust Explosion

Definition and Mechanism

Dust explosions are a type of combustible dust hazard that can cause significant damage to property and loss of life. They occur when a cloud of combustible dust is ignited and results in a rapid increase in pressure and temperature. This pressure can cause significant damage to equipment and structures, and the heat generated can lead to secondary fires and explosions.

The mechanism of a dust explosion typically involves three elements: fuel, oxygen, and an ignition source. The fuel is usually a fine dust that is suspended in the air, while the oxygen comes from the surrounding air. The ignition source can come from a variety of sources, including sparks, open flames, or hot surfaces.

Conditions for Dust Explosion

Several conditions must be present for a dust explosion to occur. These conditions are often referred to as the “dust explosion pentagon” and include the following:

-

Fuel: The presence of a combustible dust is necessary for a dust explosion to occur. Examples of combustible dust include wood, coal, grain, and plastics.

-

Oxygen: The presence of oxygen is necessary for combustion to occur. The air around us contains approximately 21% oxygen, which is typically sufficient to support combustion.

-

Ignition source: An ignition source is necessary to initiate the combustion process. Common ignition sources include sparks, open flames, and hot surfaces.

-

Dispersion: The dust must be dispersed in the air in a sufficient concentration in order for a dust explosion to occur. This concentration is often referred to as the “explosive range.”

-

Confinement: The dust cloud must be confined in a space in order for pressure to build up and an explosion to occur. This confinement can come from a variety of sources, including equipment, buildings, or other structures.

It is important to note that not all dusts are explosive, and the conditions necessary for a dust explosion to occur can vary depending on the specific dust and environment. Dust explosion screening testing can help identify the potential for dust explosions and determine appropriate prevention and mitigation measures.

Dust Explosion Screening Tests

When it comes to preventing dust explosions, screening tests are an essential tool. These tests help to identify the risks of combustible dusts and powders, and provide valuable information for managing and mitigating these risks. There are two primary types of screening tests: Go/No-Go testing and 20-L chamber testing.

Go/No-Go Testing

Go/No-Go testing is a simple screening test that can quickly determine if a dust or powder is potentially explosive. This test involves placing a small amount of the material in a metal cup and igniting it with a flame. If the material ignites and sustains a flame, it is considered a “Go” and requires further testing. If the material does not ignite or only ignites briefly, it is considered a “No-Go” and is not considered a significant explosion hazard.

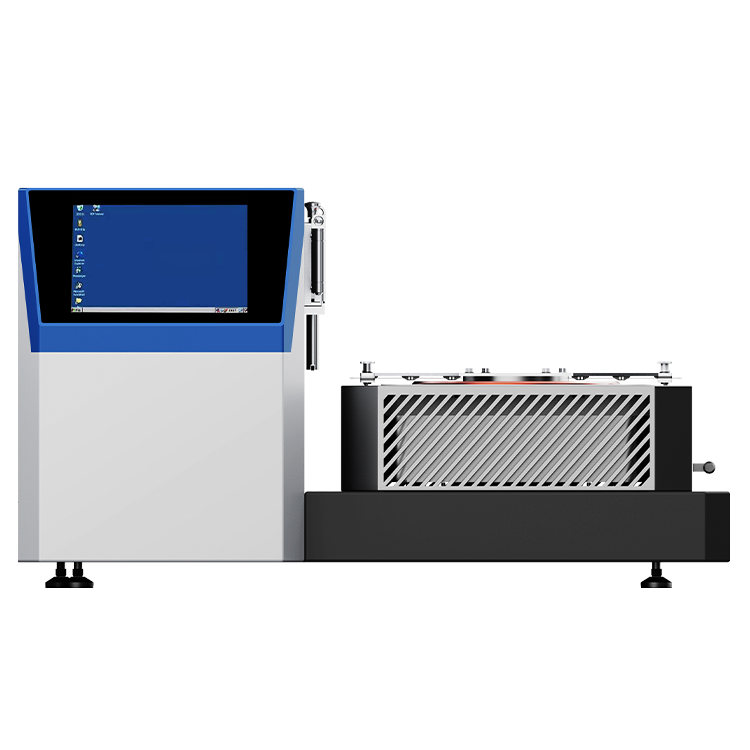

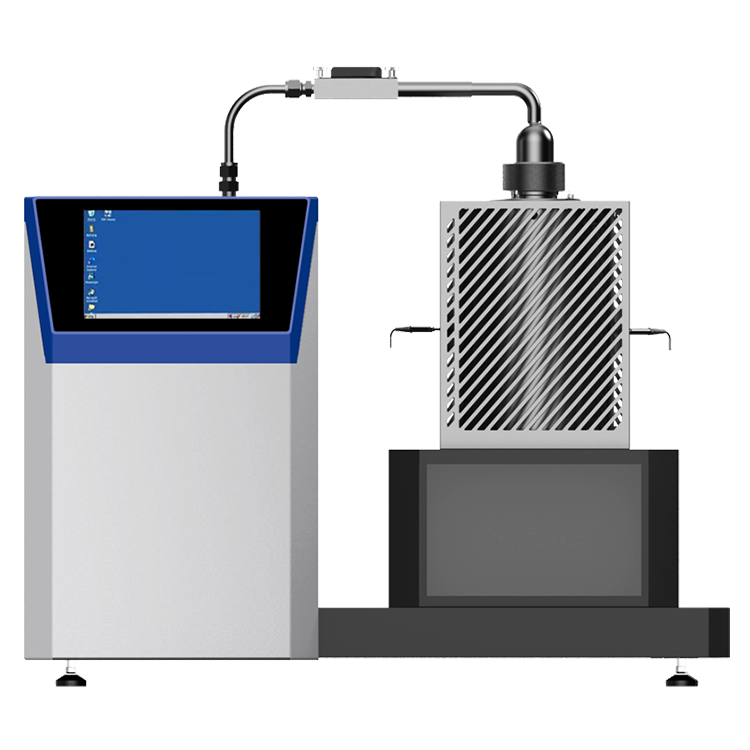

20-L Chamber Testing

20-L chamber testing is a more thorough screening test that provides more detailed information on the explosiveness of a dust or powder. This test involves placing a larger amount of the material in a 20-L chamber and introducing an ignition source. The resulting explosion is measured and analyzed to determine the maximum explosion pressure and rate of pressure rise, which can be used to calculate the Kst value of the material. If the Kst value is below a certain threshold, the material is considered to be a low explosion hazard.

Overall, screening tests are an important tool for managing the risks of combustible dusts and powders. By identifying potentially explosive materials, these tests can help to prevent devastating dust explosions and protect workers and facilities from harm.

Sample Preparation for Testing

Before conducting any dust explosion screening tests, it is essential to prepare the samples correctly. Sample preparation for testing involves two primary steps – sample collection and sample conditioning.

Sample Collection

To collect a representative sample, you must follow a few guidelines. First, identify the areas where the dust is most likely to accumulate. Second, use a clean and dry sampling tool to collect the sample. Third, collect multiple samples from different locations to ensure representativeness. Fourth, mix the samples thoroughly to form a homogenous mixture. Finally, store the sample in a clean and dry container, well-labeled, and away from any ignition sources.

Sample Conditioning

Sample conditioning is the process of preparing the sample for testing. Conditioning involves two primary steps – particle size reduction and moisture content reduction.

Particle size reduction ensures that the sample particles are small enough to pass through the testing equipment. The preferred particle size reduction method is defined by the ASTM E1226 Protocol, which requires that particle size be reduced to 95% less than 75μm.

Moisture content reduction ensures that the sample is dry enough to prevent any reaction during testing. The ASTM E1226 Protocol requires that the sample be dried to moisture content less than 5%. The most common method for moisture content reduction is by oven drying the sample at 105°C for 24 hours.

In summary, proper sample preparation is crucial for accurate dust explosion screening testing. Collecting a representative sample and conditioning it correctly ensures that the test results are reliable and consistent.

Interpretation of Test Results

After conducting dust explosion screening testing, interpreting the test results is crucial to determine the safety of the tested material. The following subsections will provide information on how to interpret test results.

Safety Parameters

The safety parameters are the key indicators of the explosibility of the tested material. The safety parameters include Minimum Explosible Concentration (MEC), Minimum Ignition Energy (MIE), and Maximum Explosion Pressure (Pmax). The MEC is the minimum concentration of dust in air required to form an explosive mixture, while the MIE is the minimum energy required to ignite the mixture. The Pmax is the maximum pressure generated by the explosion.

Interpreting the safety parameters is important to determine the potential risk of a dust explosion. If the MEC is low and the MIE is low, then there is a high risk of an explosion. On the other hand, if the MEC is high and the MIE is high, then the risk of an explosion is low. The Pmax is also an important safety parameter, as a high Pmax indicates a more severe explosion.

Risk Assessment

After interpreting the safety parameters, the next step is to conduct a risk assessment. The risk assessment involves evaluating the likelihood and consequences of a dust explosion. The likelihood of an explosion is determined by the safety parameters and the frequency and duration of dust clouds. The consequences of an explosion are determined by the Pmax and the location of the explosion.

A thorough risk assessment can help determine the appropriate safety measures to prevent a dust explosion. Safety measures may include implementing dust control measures, using explosion-proof equipment, and conducting regular maintenance and inspections.

In conclusion, interpreting the test results of a dust explosion screening test is crucial to determine the safety of the tested material. By evaluating the safety parameters and conducting a risk assessment, appropriate safety measures can be implemented to prevent a dust explosion.

Preventive and Mitigation Strategies

When it comes to preventing and mitigating dust explosions, there are two main types of strategies: explosion prevention measures and explosion protection measures.

Explosion Prevention Measures

Explosion prevention measures are designed to eliminate or reduce the likelihood of a dust explosion occurring. These measures include:

- Conducting a hazard analysis to identify potential hazards and develop appropriate safety measures.

- Implementing good housekeeping practices to keep the work environment clean and free of combustible dust.

- Using non-combustible materials in construction and equipment design.

- Conducting regular maintenance and inspections of equipment to ensure it is in good working order.

- Providing adequate ventilation to prevent the accumulation of combustible dust.

Explosion Protection Measures

Explosion protection measures are designed to minimize the damage caused by a dust explosion. These measures include:

- Installing explosion relief vents to allow pressure to escape in the event of an explosion.

- Using explosion suppression systems to detect and suppress an explosion before it can cause significant damage.

- Installing explosion isolation systems to prevent the spread of flames and pressure waves.

- Using chemical inhibitors to prevent the ignition of combustible dust.

It is important to note that explosion protection measures should not be relied on as the sole means of preventing dust explosions. Instead, they should be used in conjunction with explosion prevention measures to provide a comprehensive approach to dust explosion safety.

By implementing both explosion prevention and explosion protection measures, you can significantly reduce the risk of a dust explosion in your workplace.