MIE Test Machine: A Comprehensive Guide to Understanding Its Features and Benefits

If you are working with combustible dust, you know how important it is to ensure that your equipment and processes are safe. One key tool in your safety arsenal is the Minimum Ignition Energy (MIE) test machine. This device allows you to determine the minimum amount of energy required to ignite a dust cloud, which is essential information for preventing explosions and fires.

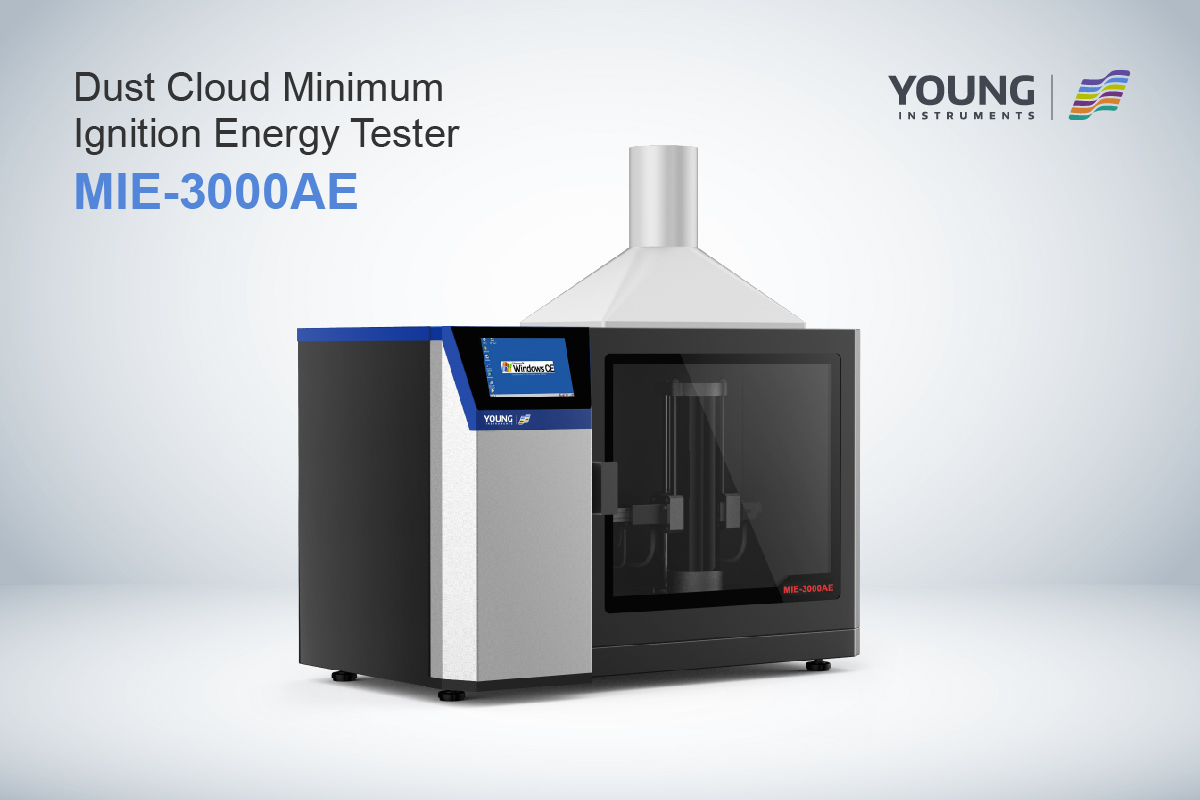

The MIE test machine is used to measure the electrical energy required to ignite a dust cloud. The test involves dispersing a cloud of dust in a test chamber and then applying an electrical spark to the cloud. The machine measures the amount of energy required to ignite the cloud, which is expressed in millijoules (mJ). The lower the MIE value, the easier it is for the dust cloud to ignite, and the greater the risk of an explosion or fire. By knowing the MIE value of dust, you can take steps to minimize the risk of ignition, such as grounding equipment, controlling static electricity, and using explosion-proof equipment.

Overview of MIE Test Machines

If you are working with combustible dust, it is important to assess the hazards of ignition by electrostatic sparks or discharges. One way to do this is by using an MIE test machine.

An MIE test machine is designed to determine the minimum energy of an electric spark needed to initiate a dust explosion. The machine generates a dust cloud in a test chamber and then applies an electric spark to the cloud. The energy required to ignite the cloud is measured, and this value is known as the minimum ignition energy (MIE).

MIE test machines are commonly used in industries such as chemical, pharmaceutical, food, and manufacturing. They are an important tool for assessing the safety of materials and processes that involve combustible dust.

There are different types of MIE test machines available on the market. Some machines use a spark gap to generate the electric spark, while others use a capacitor discharge. Some machines are designed for laboratory use, while others are portable and can be used in the field.

When selecting an MIE test machine, it is important to consider factors such as the type of dust being tested, the size of the test chamber, and the accuracy of the machine’s measurements. It is also important to follow proper safety procedures when using the machine, as the generation of a dust cloud can be hazardous.

In summary, MIE test machines are an important tool for assessing the hazards of combustible dust. They can help ensure the safety of materials and processes in a variety of industries.

Functional Components

When it comes to the MIE Test Machine, there are three key functional components that work together to provide accurate and reliable test results. These components are the Load Frame, Control System, and Measurement Devices.

Load Frame

The Load Frame is responsible for applying the necessary force to the sample being tested. It is a sturdy and robust structure that can withstand high loads and is designed to maintain the alignment of the sample throughout the test. The Load Frame is typically made of high-quality materials such as steel or aluminum and is equipped with various fixtures and grips that can be adjusted to accommodate different sample types and sizes.

Control System

The Control System is the brain of the MIE Test Machine. It is responsible for controlling the Load Frame and Measurement Devices, as well as collecting and analyzing the test data. The Control System is equipped with advanced software that allows you to set up the test parameters, monitor the test progress in real-time, and generate detailed test reports. The software is user-friendly and intuitive, making it easy for you to operate the MIE Test Machine even if you have no prior experience with testing equipment.

Measurement Devices

The Measurement Devices are the sensors and instruments that are used to measure the various parameters of the sample being tested. Depending on the type of test being performed, the Measurement Devices can include load cells, displacement sensors, strain gauges, and other types of transducers. These devices are highly accurate and sensitive, allowing you to measure even the smallest changes in the sample’s behavior during the test.

In summary, the MIE Test Machine is a sophisticated testing system that consists of three key functional components: the Load Frame, Control System, and Measurement Devices. These components work together seamlessly to provide accurate and reliable test results, making the MIE Test Machine an essential tool for any organization that needs to perform material testing.

Types of MIE Test Machines

When it comes to MIE testing, there are two main types of machines: static MIE testers and dynamic MIE testers. Each type has its own unique advantages and disadvantages.

Static MIE Testers

Static MIE testers are the most common type of MIE test machine. They work by creating a spark in a controlled environment and measuring the energy required to ignite a dust cloud. These machines are typically less expensive than dynamic MIE testers, making them a popular choice for many companies.

One of the main advantages of static MIE testers is that they are easy to use. They require little training and can be operated by almost anyone. Additionally, they are relatively small and portable, making them ideal for use in the field.

However, static MIE testers do have some limitations. They are not as accurate as dynamic MIE testers, and they can only test a limited range of dust concentrations. This means that they may not be suitable for all types of dust.

Dynamic MIE Testers

Dynamic MIE testers are more complex than static MIE testers. They work by simulating the conditions that can lead to a dust explosion, such as mechanical sparks or electronic discharges. These machines are typically more expensive than static MIE testers, but they are also more accurate.

One of the main advantages of dynamic MIE testers is that they can test a wider range of dust concentrations. This makes them ideal for testing a variety of different types of dust. Additionally, they are more accurate than static MIE testers, meaning that they can provide more reliable results.

However, dynamic MIE testers are more complex than static MIE testers, and they require more training to operate. They are also larger and less portable, making them less suitable for field use.

Overall, the type of MIE test machine you choose will depend on your specific needs and requirements. Whether you choose a static MIE tester or a dynamic MIE tester, it is important to ensure that you use a machine that is accurate, reliable, and easy to use.

Applications and Uses

MIE Test Machines are versatile and can be used in a variety of applications across different industries. Some of the most common applications of MIE Test Machines include material characterization, product testing, and quality control.

Material Characterization

MIE Test Machines are commonly used in material characterization to determine the minimum ignition energy of a dust. This information is crucial in assessing the hazards of ignition by electrostatic sparks or discharges. Electrostatic sparks and discharges can be generated from many activities, including conveying, mixing, and processing of powders and bulk solids. By characterizing the minimum ignition energy of a dust, you can determine the level of risk associated with handling the material and take appropriate measures to mitigate the risk.

Product Testing

MIE Test Machines are also used in product testing to assess the safety of products that may generate dust or other combustible materials. For example, MIE testing is commonly used in the automotive industry to assess the wear resistance of textiles used in the manufacturing of car seats and other interior components. By measuring friction, the MIE test machine accurately determines the durability of various textile types, including woven, knitted, composite, plastic, and coated textile lining skins.

Quality Control

MIE Test Machines are also used in quality control to ensure that products meet certain safety standards. For example, in the food and beverage industry, MIE testing is used to assess the risk of dust explosions in food processing plants. By characterizing the minimum ignition energy of dust generated during the processing of food products, you can determine the level of risk associated with handling the material and take appropriate measures to mitigate the risk.

Overall, MIE Test Machines are a valuable tool for assessing the risk of dust explosions and ensuring the safety of products and materials across a variety of industries.

Maintenance and Safety

Routine Maintenance

To ensure the MIE Test Machine functions optimally and produces accurate results, you should conduct routine maintenance on it. Regular maintenance will help you identify and fix issues before they become severe. Here are some routine maintenance tasks you should perform on your MIE Test Machine:

-

Clean the machine: Regularly clean the MIE Test Machine to remove dust and debris that may affect its performance. Use a soft cloth and mild detergent to clean the machine’s exterior. For the interior, use a vacuum cleaner to remove dust and debris.

-

Check the power supply: Ensure the machine’s power supply is stable and consistent. Regularly check the cables and connections for any signs of damage.

-

Calibrate the machine: Regularly calibrate the MIE Test Machine to ensure it produces accurate results. You can calibrate the machine using a calibration kit that comes with the machine.

Safety Precautions

When using the MIE Test Machine, you should take the necessary safety precautions to prevent accidents and injuries. Here are some safety precautions to observe when using the MIE Test Machine:

-

Wear protective gear: Always wear protective gear such as gloves, goggles, and a lab coat when handling the MIE Test Machine. This will protect you from any harmful dust and chemicals.

-

Follow the manufacturer’s instructions: Read and follow the manufacturer’s instructions when using the MIE Test Machine. This will help you use the machine correctly and safely.

-

Ensure proper ventilation: Ensure the room where you use the MIE Test Machine is well-ventilated to prevent the accumulation of dust and fumes.

-

Keep the machine clean: Regularly clean the MIE Test Machine to prevent the accumulation of dust and debris that may affect its performance.

By following these routine maintenance and safety precautions, you can ensure the MIE Test Machine functions optimally and safely.