Automatic Vapor Pressure Tester for Micro Vapor Pressure Analysis

Vapor pressure is a crucial characteristic of volatile substances, indicating the pressure of a vapor in equilibrium with its liquid or solid form at a particular temperature. Accurate analysis of vapor pressure is vital in various industries, especially petroleum and chemicals, to ensure safety and product quality. The automatic vapor pressure tester, employing the triple expansion method, serves this purpose by precisely measuring the volatility of liquids. This device is particularly suited for analyzing substances like gasoline, aviation gasoline, hydrocarbon solvents, light petroleum distillates, and chemical reagents, making it an indispensable tool for maintaining the integrity and compliance of products within these sectors.

Methods for Vapor Pressure Determination

Three-Stage Expansion Method

The three-stage expansion method, utilized for determining vapor pressure, encompasses injecting a known volume of the test sample into a sealed cylinder, controlling it at a specified temperature, and then expanding the sample volume in three sequential stages. The total pressure after each expansion stage is measured, enabling calculation of the dissolved air’s partial pressure. Subtracting this partial pressure from the total vapor pressure yields the sample’s vapor pressure. This method finds application in standards such as SH/T 0769, SN/T 2932, and ASTM D6378, offering a precise measurement approach for volatile liquids within specific temperature and pressure ranges.

Micromethod

For petroleum products, the micromethod, as outlined in ASTM D5191 and SH/T 0794, offers an alternative means of vapor pressure determination. By saturating a known volume of the sample with air at a specific temperature, subsequent observation of pressure changes allows for the calculation of total vapor pressure. This method’s meticulous procedure involves air saturation and precise temperature control, ensuring accurate results, particularly for petroleum products with specific boiling points and vapor pressure ranges.

Reid Method

The Reid method, described in standards like GB/T 8017 and ASTM D323, involves injecting a cooled test sample into a vapor pressure measuring device, connected to a gas chamber maintained at 37.8°C. Subsequent oscillations and temperature control lead to stabilized pressure readings, from which the Reid vapor pressure is derived. Though widely used, this method’s reliance on human operations and longer analysis times poses certain limitations.

Comparative Analysis

Compared to the micromethod and Reid method, the three-stage expansion method offers advantages such as reduced loss of volatile components, shorter analysis times, and minimized human errors. Its simplicity and efficiency make it the preferred choice for vapor pressure determination in various industries.

Objectives

Key Objectives of the Automatic Vapor Pressure Tester

The primary objective of the automatic vapor pressure tester is to provide a reliable, accurate, and efficient means of measuring the vapor pressure of liquids. This tool aims to overcome the limitations of traditional methods by offering:

- Precision: Enhanced accuracy in measurements, crucial for quality control and safety in industrial applications.

- Speed: Faster results than traditional methods, facilitating quicker decision-making processes.

- Versatility: The Capability to test a wide range of substances, from highly volatile to low volatility products.

Desired Features and Capabilities

The automatic vapor pressure tester is designed with several key features to meet industry needs:

- Automation: Fully automated operations to reduce human error and increase repeatability of results.

- Data Integration: Capability to integrate with laboratory information management systems (LIMS) for seamless data management.

- Environmental Control: Built-in temperature regulation to ensure precise control over testing conditions.

- Safety Features: Advanced safety features to handle volatile substances safely and prevent laboratory accidents.

Operating Principle

Explanation of How the Tester Measures Vapor Pressure

The tester measures vapor pressure based on the triple expansion method, which accurately gauges the equilibrium pressure of vapors above a liquid sample. Once the sample is placed into the tester, it rapidly adjusts to the pre-set temperature while the pressure is continuously monitored and recorded, providing precise vapor pressure readings.

Control Algorithms for Temperature Regulation and Pressure Monitoring

The device employs advanced control algorithms to maintain the desired temperature and pressure settings:

- Temperature Regulation: Utilizes feedback loops to make minute adjustments to the heating element, ensuring the temperature remains within ±1°C of the target.

- Pressure Monitoring: Continuously measures the pressure within the sample chamber with high sensitivity, adjusting operational parameters in real-time to maintain accuracy.

Calibration Procedures for Accuracy and Reliability

Calibration is essential for maintaining the tester’s accuracy:

- Routine Calibration Checks: Periodically performed using standard calibration gases and liquids to ensure ongoing accuracy.

- Repeatability and Reproducibility Tests: Conducted to confirm that the measurements are consistent over multiple tests and across different machines.

Specifications

- Operating Environment: 5°C to 40°C, humidity less than 85% RH

- Pressure Detection Range: 0 to 1000 kPa

- Sample Test Amount: 1mL, with about 10mL required for thrice rinsing

- Gas-to-Liquid Ratio: Adjustable from 0.02:1 to 4:1

- Connectivity: RS232, RJ45, and USB interfaces for comprehensive connectivity options

- Power Requirements: AC220V/50Hz, with a power consumption of 150W

- Dimensions: Compact at 225mm x 290mm x 390mm

The automatic vapor pressure tester is a sophisticated device tailored for accurate and efficient vapor pressure testing, making it an invaluable tool in industries where liquid volatility is a critical parameter.

Design and Components

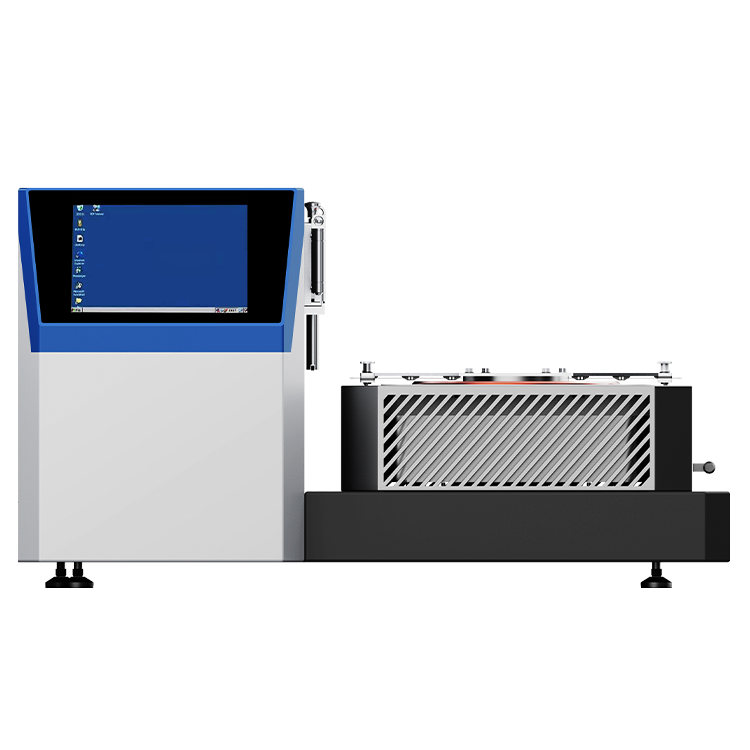

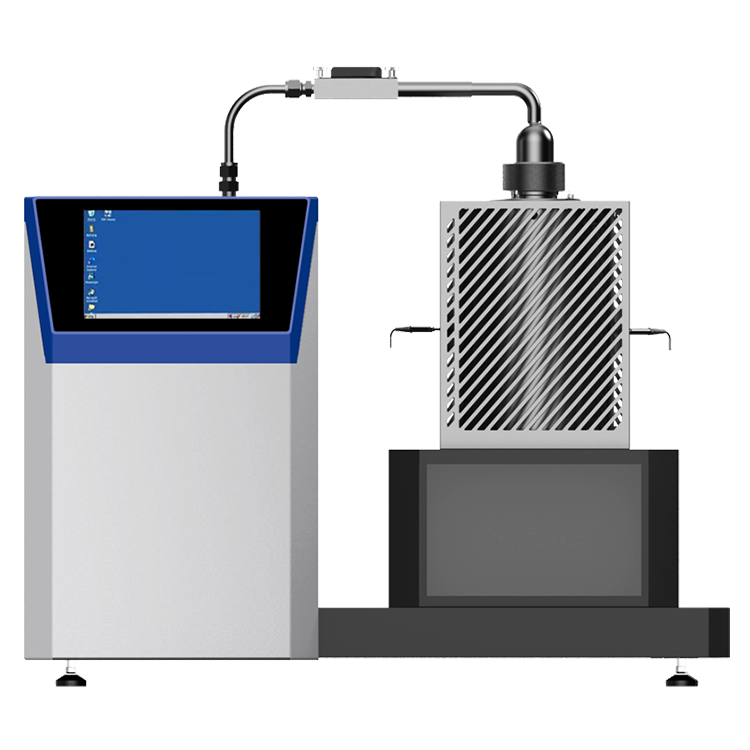

Overview of the System Architecture

The system architecture of the automatic vapor pressure tester is designed to offer a streamlined and efficient approach to vapor pressure measurement. Utilizing the advanced triple expansion method, the tester requires minimal sample handling and integrates various automated features to enhance accuracy and reduce operational time.

Description of Main Components

- Sample Chamber: The heart of the tester, where 1 ml of the sample is introduced for testing. It is designed to be maintenance-free and suitable for high-intensity tasks.

- Pressure Sensor: Highly sensitive and accurate, capable of detecting minute changes in pressure with a resolution of 0.01 kPa.

- Temperature Control System: Ensures precise temperature settings from 0 to 120°C with an accuracy of ±1°C, crucial for the accuracy of vapor pressure measurements.

Integration of Automation Technology

Automation is a key feature of this system:

- One-Button Operation: Simplifies the experimental process by allowing operations to be conducted with a single button, reducing the potential for human error.

- Automated Temperature and Pressure Adjustments: Automatically detects and adjusts multiple temperature points, swiftly compiling temperature-pressure reference charts.

- Unique Cleaning Method: Reduces sample cross-contamination, thereby enhancing the precision and efficiency of subsequent tests.

Applications

Industries and Research Fields That Benefit from Micro Vapor Pressure Analysis

Micro vapor pressure analysis is crucial across various sectors, primarily in the petroleum and chemical industries, where precise measurements of vapor pressure are required to ensure product stability and compliance with safety regulations. Additionally, the pharmaceutical, environmental science, and food industries benefit from this technology to monitor the volatility and preservation of products.

Examples of Specific Applications and Case Studies

Petroleum Industry: For determining the vapor pressure of gasoline and aviation fuels, ensuring that they meet volatility standards for optimal engine performance and safety.

Chemical Manufacturing: In producing hydrocarbon solvents and light petroleum distillates, micro vapor pressure analysis ensures that products are within required volatility specifications to prevent hazardous conditions.

Environmental Monitoring: Used in studying the evaporation rates of pollutants in water and air, aiding in environmental assessments and remediation strategies.

Future Potential for Expanding Applications

The technology’s potential extends into areas like renewable energy, where the volatility of biofuels needs precise characterization, and in advanced material science, where the stability of novel compounds under varying atmospheric conditions is critical.

Performance Evaluation

Assessment of Accuracy and Precision Compared to Traditional Methods

The micro vapor pressure tester offers superior precision and accuracy compared to traditional methods like the Reid Vapor Pressure test. It achieves this through controlled automation, reducing human error and increasing the repeatability of results. Studies have shown that the triple expansion method can measure vapor pressures with a precision of less than 0.3 kPa and an accuracy deviation of ±0.1°C in temperature control.

Comparison with Existing Automatic Vapor Pressure Testers

When compared to other automatic testers, this device stands out due to its ability to manage very low vapor pressures and its faster processing time of 10 minutes per sample. The unique cleaning system also minimizes cross-contamination, setting it apart in terms of reliability and efficiency.

Feedback from Users and Recommendations for Improvement

User feedback has generally been positive, particularly praising the tester’s ease of use, quick results, and the low sample volume requirement. However, some users have suggested improvements in the user interface for even simpler navigation and more integration options with external data systems to enhance laboratory workflows. Future upgrades might also focus on expanding the device’s temperature range to accommodate a wider variety of sample types and conditions.

Closing Words

The Automatic Vapor Pressure Tester for Micro Vapor Pressure Analysis represents a significant technological advancement in the measurement of liquid volatility. The device uses a cutting-edge triple amplification method. Delivering unparalleled precision and efficiency, requiring minimal sample volumes and delivering results in minutes. Its powerful automation and innovative features make it a critical tool for industries where vapor pressure data impacts product quality and safety. Going forward, there is huge potential for this technology to expand into new areas and new applications. It is expected to meet the changing industrial needs. Whether in the field of petroleum, chemical production or environmental monitoring. This tester will redefine standards and enhance operational capabilities across different industries.