Exploring Directional Heat Flow: Anisotropy Thermal Conductivity Testing

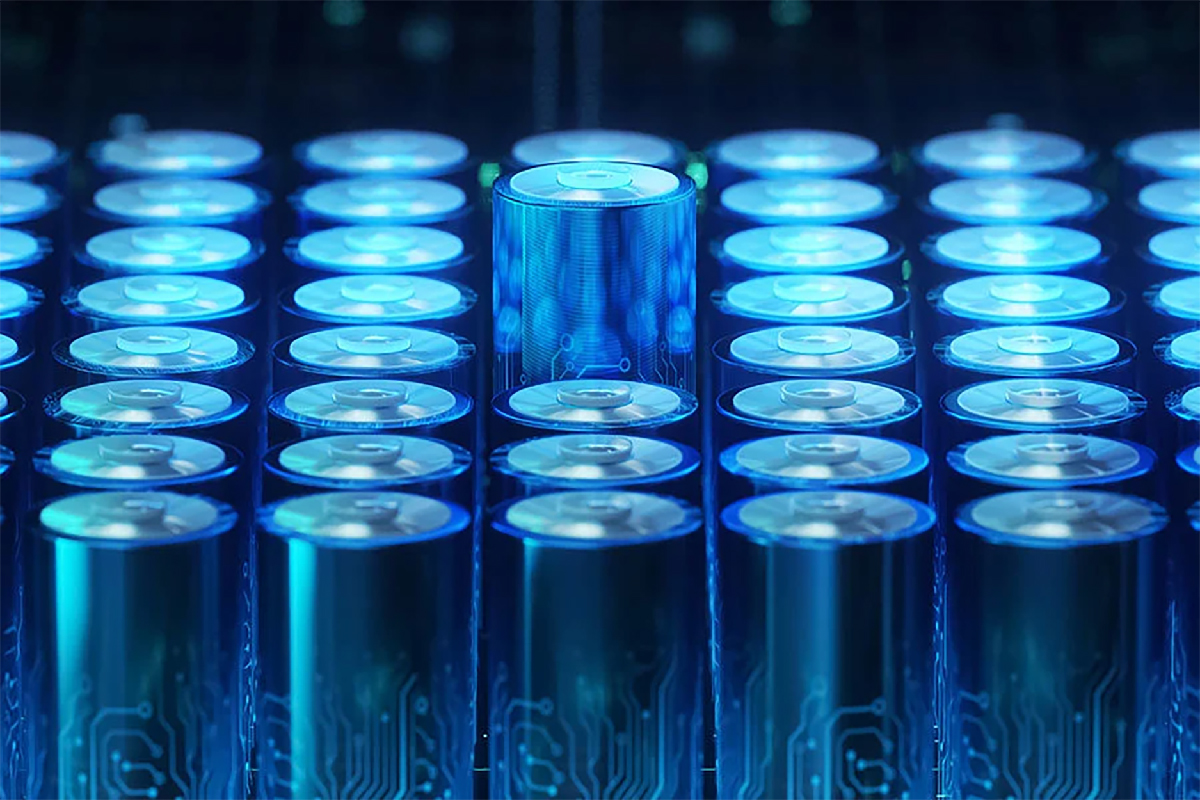

In various applications like lithium batteries, precise measurement of anisotropic thermal conductivity plays a crucial role in efficient heat regulation. Lithium batteries, characterized by their multi-layered composite structures, require a comprehensive evaluation of both lateral and longitudinal thermal conductivities.

The intricate nature of their composite microstructure, coupled with the fluctuating thermal properties and temperature variations, presents substantial hurdles in ensuring accurate thermal management, crucial for optimizing battery performance and safety. Essentially, lithium batteries consist of multiple layers of composite materials, including aluminum-plastic film, positive and negative electrode materials, separators, current collectors, and electrolytes. The comprehensive thermal conductivity of the battery encompasses both lateral and longitudinal aspects.

Anisotropy Thermal Conductivity Testing With the thermal properties of battery materials and the composite microstructure varying with temperature, the battery’s thermal conductivity exhibits temperature-dependent behavior. Therefore, acquiring data on the battery’s thermal conductivity under temperature changes within its normal operating range holds significant importance in enhancing the precision and efficacy of thermal management simulations.

3D Thermal Properties Analyzer TCA 3DP-160

Overview

The TCA3DP-160 is a state-of-the-art 3D thermophysical property analyzer, leveraging advanced technologies such as infrared thermal imaging and three-dimensional data inversion. Designed to apply pulse excitation via a flexible electric heater to the bottom of a soft-pack lithium battery, it utilizes non-contact infrared thermal imaging on one side of the battery to measure temperature. This setup facilitates the determination of both longitudinal and oriented thermal conductivities through data inversion calculations, making it an invaluable tool for thermal simulation designs of soft-pack batteries.

Applicable Fields

This versatile equipment is particularly useful in the analysis of soft-pack lithium batteries and composite materials, accommodating a diverse range of homogeneous and heterogeneous samples. It is tailored for samples varying in specification, surface hardness, roughness, and porosity.

Features

- Adaptability: Capable of testing a wide range of sample sizes, accommodating specific requirements for surface flatness.

- Non-Destructive Testing: Allows for the accurate measurement of the equivalent thermal conductivity of multi-layer thin film stacks without damaging the samples.

- Precision Control: Features uniform temperature control across six-sided cold plates, high-precision oil bath temperature control, and an adjustable ambient temperature to ensure consistency in measurements.

- Advanced Measurement Techniques: Incorporates non-contact measurement with automatic compensation for any interferences caused by surface and support heat dissipation, thereby enhancing the accuracy of results.

- User-Friendly Interface: Offers simple instrument operation with fully automated experiment initiation and execution. It includes a color graphics display that showcases test data, predicted data, error data, and an error assessment for rapid validation of experimental outcomes.

- Data Management: Automatically generates and saves graphs and process data, and provides support for historical data queries.

Specifications

The TCA 3DP-160 is equipped with comprehensive specifications:

- Thermal Conductivity Range: For longitudinal measurements, the range is 0.2W/(m-K) to 5W/(m-K), and for transverse measurements, it is from 5W/(m-K) to 100W/(m-K).

- Thermal Diffusivity Range: The longitudinal thermal diffusivity spans from 0.1 mm²/s to 2 mm²/s, and the transverse range is from 2 mm²/s to 50 mm²/s.

- Sample Size: It can accommodate transverse sample sizes up to 400mm by 250mm, and longitudinal samples from 3mm to 20mm.

- Duration: Each measurement takes less than 10 minutes.

- Repeatability: The device maintains a repeatability of less than 3%.

- Temperature Range: The operational temperature range is from 0 to 60°

- Temperature Stability: Temperature stability is maintained at 0.03°

- Temperature Accuracy: The temperature accuracy of the system is 0.1°

This comprehensive setup makes the TCA 3DP-160 an indispensable tool for industries requiring precise thermal property analysis.

Dual-State Thermal Parameter Tester TCA 2SC-080

Overview

The TCA 2SC-080 employs advanced non-contact temperature measurement through infrared thermography combined with 3D heat transfer model inversion analysis technology. It is specifically designed for evaluating heterogeneous core-shell structured samples and is particularly effective for direct, non-destructive testing of the thermal conductivity and internal thermal resistance of hard-shell lithium battery cells.

Applicable Fields

This tester is ideally suited for square and cylindrical battery formats, addressing the specific needs of these applications.

Features

- Non-Destructive Testing: Provides in-situ, accurate measurement of multidimensional thermal conductivity for battery samples, preserving their integrity.

- Versatility: Capable of testing a broad range of sample sizes, even those with low surface flatness requirements.

- Smart Automation: Features automatic setting of experimental parameters based on the sample information, with dynamic adjustments during the test process to ensure optimal results.

- Comprehensive Analysis: Utilizes a 3D heat transfer model for detailed testing and inversion analysis, measuring core transverse thermal conductivity, core longitudinal thermal conductivity, and overall equivalent thermal conductivity.

- Realistic Simulation Support: Integrates with external battery charging and discharging equipment to simulate actual thermal conditions experienced during these processes.

- Adjustable Conditions: Offers adjustable sample cold plate temperatures and flow rates to mimic different heat dissipation scenarios.

- High Precision Control: Maintains uniform temperature across six-sided cold plates, high-precision oil bath temperature control, and adjustable ambient temperatures.

- User-Friendly Operation: Simplifies use with fully automated test initiation and execution.

Specifications

- Test Parameters: Measures core transverse and longitudinal thermal conductivity, core-shell contact thermal resistance, and overall equivalent thermal conductivity.

- Maximum Sample Size: Can accommodate samples up to 400mm×250mm×

- Duration: Each test completes in less than 15 minutes.

- Repeatability: Less than 8% for core transverse thermal conductivity and less than 10% for core longitudinal thermal conductivity.

- Accuracy: Less than 10% in both overall equivalent transverse and longitudinal thermal conductivity.

- Temperature Range: Operates from 0 to 80°

- Temperature Stability: Maintains a stability of 0.03°

- Temperature Accuracy: Ensures a temperature accuracy of 0.1°

The TCA 2SC-080 is a cutting-edge tool designed for precision testing of battery samples under various thermal conditions, enhancing the understanding and development of battery technologies.

Final Words

Exploring the complexities of directional heat flow through anisotropy thermal conductivity testing unlocks significant advancements in material science and engineering. By precisely measuring and understanding the varied heat flow in different directions within materials, engineers and scientists can tailor materials for specific applications, improving efficiency and performance across industries such as electronics, aerospace, and construction. The development of specialized equipment like the TCA 3DP-160 and TCA 2SC-080 enhances our ability to not only measure these unique properties accurately but also apply this knowledge to innovate and solve practical thermal management challenges. This continued exploration and refinement of anisotropic thermal conductivity testing promise to drive further breakthroughs in technology and material design, ensuring materials not only meet but exceed the demands of modern applications.