Ensuring Safe Power: Essential Battery Safety Testing Equipment

Battery safety testing equipment is crucial to guaranteeing the dependability and safety of batteries across diverse applications, ranging from consumer electronics to electric vehicles. With the increasing demand for high-performance batteries, rigorous testing is imperative to prevent malfunctions and adhere to safety regulations. This equipment assesses thermal stability, electrical performance, and environmental durability, enabling manufacturers to detect potential issues early in the development process. By employing advanced safety testing equipment, companies can improve battery performance, mitigate risks, and ensure compliance with stringent regulatory standards.

Product Introduction

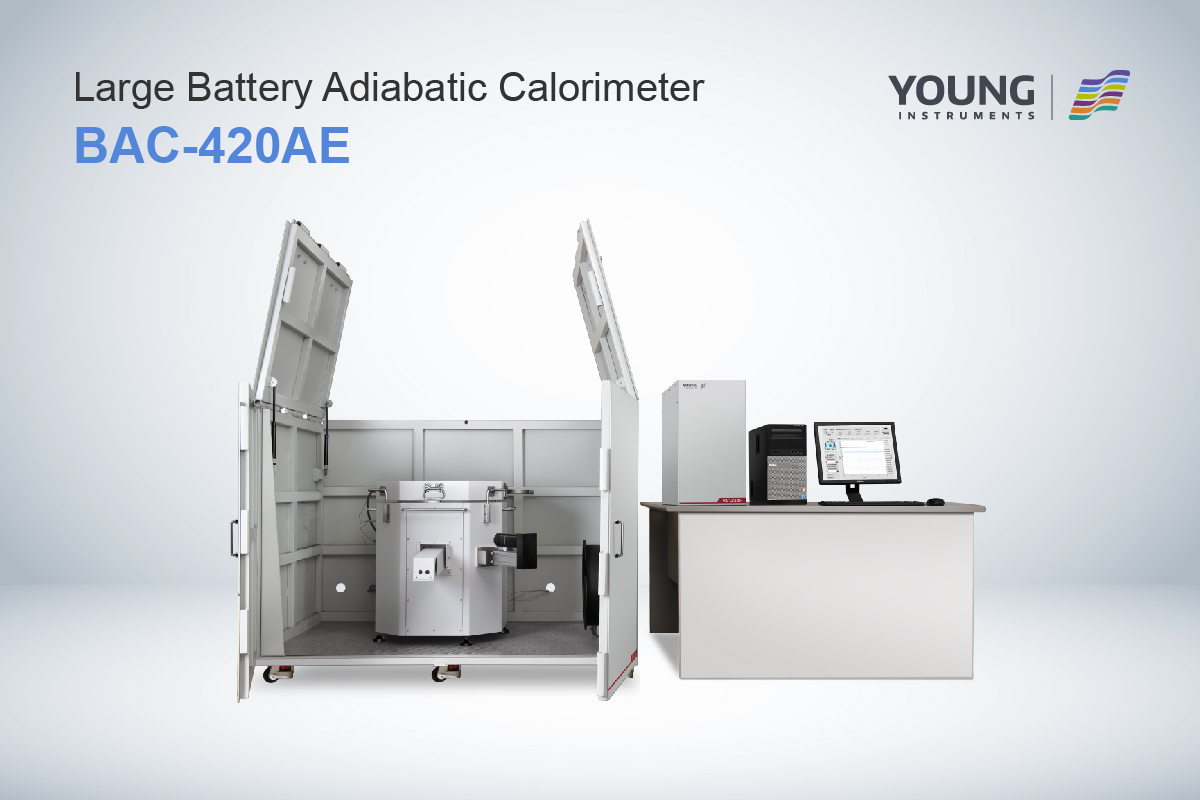

Precise Adiabatic Environment

The large-scale Battery Adiabatic Calorimeter BAC-420AE is essential for conducting various thermal runaway tests. Its key feature is the ability to provide a precisely controlled adiabatic environment. This capability allows for the comprehensive characterization of battery thermal runaway parameters, crucial for designing effective battery thermal management systems and ensuring early detection and prevention of thermal runaway events.

Comprehensive Testing Capabilities

The BAC-420AE simulates adiabatic environments to measure critical battery and module thermal characteristics accurately. It determines the thermal runaway onset temperature, maximum thermal runaway rate, adiabatic temperature rise, and more. The integrated battery charge/discharge module supports mode switching, constant current/constant voltage charge modes, and real-time battery capacity calculation, enhancing the equipment’s versatility and functionality.

Enhanced Data Analysis and Accuracy

This equipment synchronizes battery voltage, current, temperature, and external pressure data, allowing for detailed analysis of current and voltage changes during thermal runaway. Additionally, the BAC-420AE improves battery specific heat testing accuracy through a unique testing process, providing precise data critical for battery safety and performance optimization.

Product Functions and Testing Parameters

Comprehensive Testing Functions and Parameters

The Battery Adiabatic Calorimeter BAC-420AE offers a range of functions to ensure thorough battery testing. It can handle thermal, electrical, and mechanical abuse, specific heat testing, visual/infrared imaging, thermal runaway gas analysis, and charge/discharge heat generation testing. These tests help determine critical parameters such as battery thermal runaway characteristics, adiabatic temperature rise, specific heat capacity, charge/discharge heat generation power, pressure rise rate, and maximum gas production pressure, providing a complete safety profile for batteries.

Versatile Testing Modes

The BAC-420AE supports multiple testing modes, including HWS mode, specific heat capacity testing mode, charge/discharge heat generation mode, adiabatic temperature rise testing mode, temperature difference baseline mode, scanning mode, and constant temperature mode. These modes can be customized to meet specific experimental requirements. Calibration with the temperature difference baseline mode is essential before conducting HWS mode and charge/discharge heat generation mode experiments, ensuring accurate and reliable results.

Related Testing Standards

GB/T 36276: Comprehensive Safety Evaluation

GB/T 36276 is a crucial standard for lithium battery safety, particularly for energy storage applications. It focuses on detecting whether batteries ignite or explode during thermal runaway. This standard also requires testing the adiabatic temperature rise during battery charge and discharge cycles. By adhering to GB/T 36276, manufacturers can ensure that their batteries meet stringent safety criteria, preventing hazardous incidents and enhancing overall safety.

UL 9540A: Fire Safety Assessment

UL 9540A is designed to evaluate the ignition characteristics of energy storage system cells during thermal runaway. This standard provides essential data for fire safety assessments, helping to determine effective fire and explosion prevention measures for energy storage systems. By complying with UL 9540A, manufacturers can ensure their systems are equipped with robust fire safety mechanisms, minimizing risks associated with thermal runaway incidents.

UL 1973: Systemic Impact Analysis

UL 1973 focuses on assessing the impact of cell thermal runaway on surrounding cells and the overall battery system. This standard provides critical data to help reduce the impact of individual cell failures through better cell design and system integration. Compliance with UL 1973 ensures that battery systems are designed to mitigate the effects of thermal runaway, enhancing the safety and reliability of the entire system.

In Sum

Advanced safety testing equipment plays a critical role in improving battery performance and guaranteeing their dependability across diverse applications. It enables precise measurement of thermal, electrical, and mechanical properties, allowing manufacturers to detect and address potential risks related to battery operation. This thorough testing not only ensures compliance with rigorous safety standards but also enhances overall design and production quality. Zeal Instruments offers comprehensive lithium battery thermal testing solutions, helping battery manufacturers, automotive companies, phone manufacturers, and research institutions worldwide develop higher quality lithium batteries.