Spark Testing Precision: Ignition Sensitivity Exploration

Dust explosion refers to the rapid combustion of a combustible dust-air mixture formed in a confined space, ignited by a spark, resulting in a sudden increase in temperature and pressure. A metal dust explosion occurs when metal dust mixes with air in a confined space and explodes under energy influence. Common metals prone to dust explosions include aluminum, magnesium, titanium, and zinc.

Characteristics of Metal Dust Explosions

Metal dust is highly sensitive to ignition and has a high oxidation heat value, making the consequences of explosions extremely severe.

Most metal powders have a minimum ignition energy (MIE) of less than 10 mJ. For ultrafine metal powders, the MIE is even lower than 1 mJ, indicating a strong ignition sensitivity. Common ignition sources for dust explosions include high-temperature surfaces, impact or friction, and electrostatic sparks. Due to their high ignition sensitivity, metal dust can easily catch fire from sources such as electrostatic sparks, leading to dust explosion incidents.

The energy density of combustible dust clouds is generally higher than that of combustible gases, and metal particles have the highest energy density among combustible dusts. The heat released when metal dust consumes 1 mole of oxygen is typically three times that of coal dust, as shown in the table below. Due to this characteristic, metal dust is often used as solid fuel in rocket propellants and other aerospace applications. When high-energy-density metal dust ignites and explodes, it produces immense explosion pressure and a high rate of pressure rise instantaneously, resulting in severe accident consequences.

Introduction to Minimum Ignition Energy

Minimum ignition energy (MIE) is a critical parameter for assessing the combustion and explosion hazards of combustible gases, vapors, and dusts. It defines the minimum spark energy required to ignite a dust cloud or combustible gas-air mixture, also known as minimum spark ignition energy or critical ignition energy. Understanding MIE helps in evaluating the safety and potential risks in industrial environments where combustible dust is present.

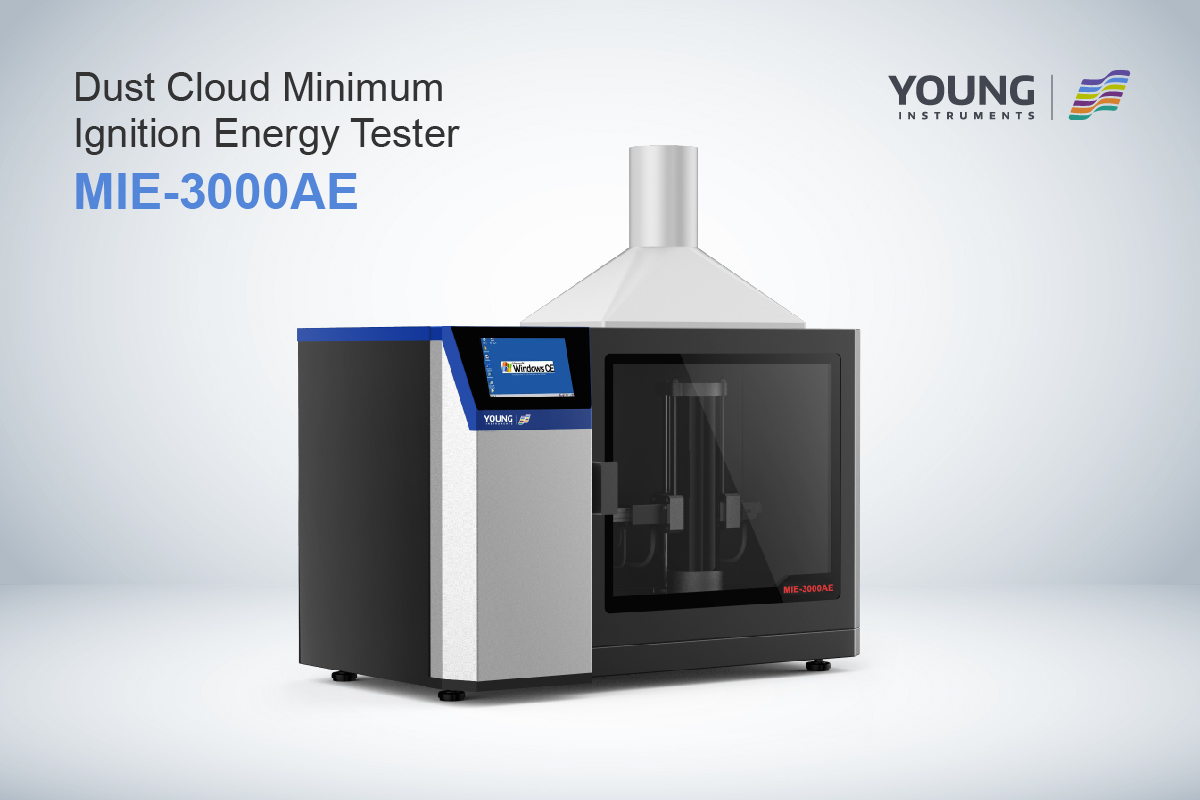

Dust Cloud Minimum Ignition Energy Tester

The Dust Cloud Minimum Ignition Energy Tester, model MIE-3000AE, is designed to perform Ignition Sensitivity Testing, evaluating the potential explosion hazards of dust clouds. This instrument disperses a specific mass of dust sample into a Hartmann tube using compressed air at a specified pressure, forming a dust cloud. The cloud is then ignited using designated spark energy, and a series of tests are conducted to determine the dust sample’s MIE. This process reflects the sensitivity of dust ignition from an energy perspective, crucial for assessing explosion risks.

International Testing Standards and Custom Definitions

The MIE-3000AE adheres to international testing standards and provides both standard parameter testing and the ability to define custom parameters. This flexibility ensures precise and adaptable testing for various applications.

Automatic Optimization and Safety Enhancements

The device automatically selects the optimal capacitor and voltage combinations for input ignition energy values, enhancing operational efficiency. Additionally, it features an automatic high-voltage charging module disconnection to improve safety during use.

Advanced Dust Dispersion and Adjustable Settings

A well-designed dust dispersion device ensures uniform distribution of dust samples, improving test accuracy. The MIE-3000AE also allows for flexible adjustments of electrode distance, powder pressure, and delay time, accommodating various testing requirements.

Maintenance and Safety Features

The device includes an automatic recording system for electrode ignition counts, prompting timely replacements to prevent any impact on test results. The Hartmann tube is easy to clean, equipped with a lifting and rotating mechanism that saves experimental time. Remote ignition control enhances personnel safety, and user hierarchy management ensures secure account control.

User-Friendly Interface and Data Management

The MIE-3000AE features a USB plug-and-play interface for convenient data management. A 7-inch color LCD touchscreen provides a dynamic display of the experimental process, offering a user-friendly human-machine interface that simplifies operation and monitoring.

Compliance with standards

The MIE-3000AE operates in environments ranging from 5℃ to 45℃ with humidity below 85%RH. It supports both standard and custom mode spark energies, ranging from 1mJ to 3000mJ, adjustable in 1mJ steps. The charging voltage ranges from 0 to 15kV, and it uses a 1.2L Hartmann tube as the experimental container. The instrument features 2mm tungsten electrodes with adjustable distances from 2mm to 10mm, a high voltage relay trigger method, and adjustable ignition delay time and powder pressure. It includes USB interfaces and operates on a power supply of 90VAC to 260VAC, 47Hz to 63Hz, with a power consumption of 300W.

Closing Words

Metal dust explosions pose significant hazards in industrial settings due to their sensitivity to ignition and the serious aftermath of explosions. Understanding key characteristics of metal dusts, such as their low ignition energy and high energy density, is crucial for preventing disastrous incidents. The Dust Cloud Minimum Ignition Energy Tester (MIE-3000AE) plays a vital role in assessing explosion risks by precisely measuring the minimum ignition energy of dust clouds. To effectively mitigate the risks associated with metal dust explosions, rigorous dust control procedures, regular equipment maintenance, and comprehensive staff training are essential, thereby fostering a safer industrial environment.