Heat Flow Meter Analyzer for Accurate Thermal Analysis

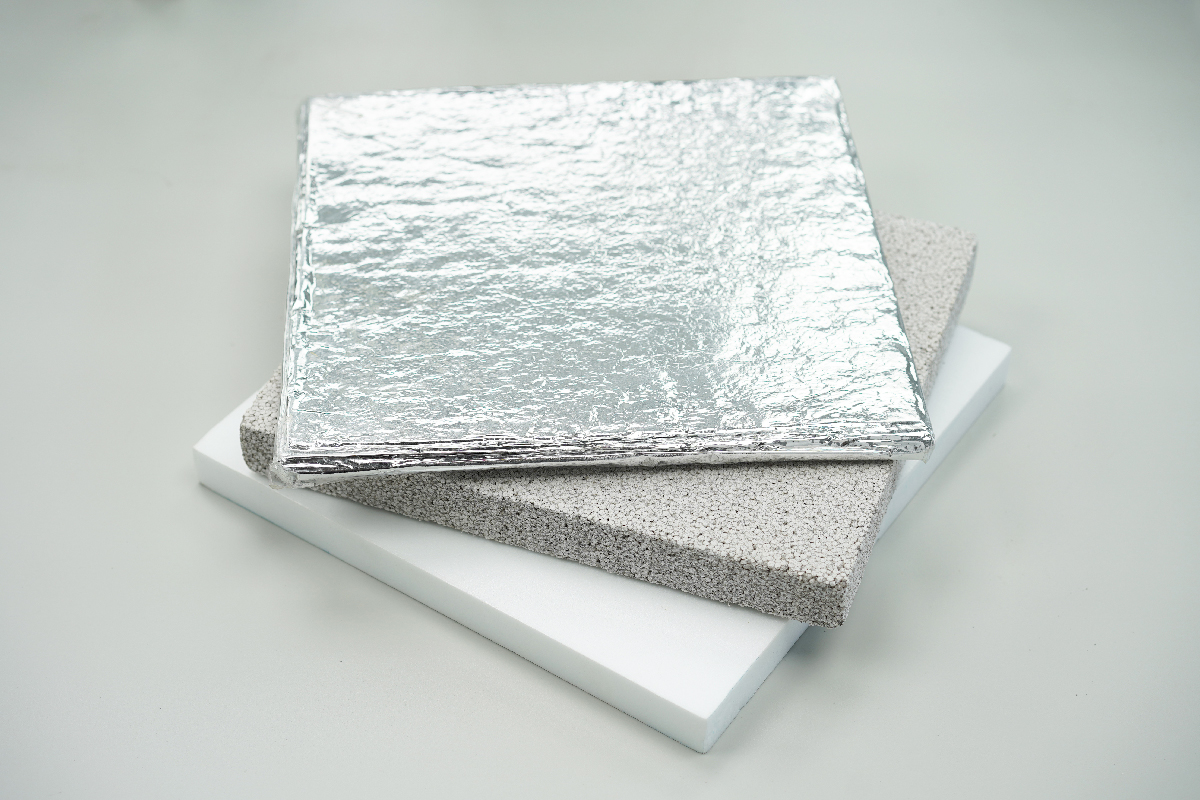

The heat flow meter measures the thermal conductivity and insulation properties of various materials. It’s crucial in research, development, and quality control across multiple industries. It assess materials like expanded polystyrene (EPS), extruded polystyrene (XPS), rigid polyurethane foam, mineral wool, expanded perlite, foam glass, cork, and wool. It also effective with natural fiber materials, building materials with phase change materials, aerogels, concrete, gypsum, and polymers. Its ability to handle such a diverse range of materials makes it an indispensable tool for ensuring material performance and compliance.

Basic Principle of the Heat Flow Meter

During testing, the material is sandwiched between two plates that maintain a constant temperature gradient. These plates are carefully calibrated to ensure consistent and accurate temperature control, which is crucial for reliable measurements. The sample’s placement is vital to minimize thermal resistance at the interfaces, ensuring that the heat flow through the material is accurately captured.

Two high-precision heat flow sensors embedded in the plates measure the heat flow into and out of the material. These sensors detect the minute differences in temperature and convert this information into a heat flow reading. The sensors’ accuracy and precision are critical, as they directly affect the reliability of the thermal conductivity measurement. When the system reaches thermal equilibrium, the heat flow remains constant, indicating steady-state conditions necessary for accurate assessment.

Once equilibrium is achieved, the constant heat flow power, combined with the known measurement area and thickness of the sample, allows for the calculation of thermal conductivity. This is done using Fourier’s heat conduction equation, which relates the heat flow rate, temperature gradient, and material dimensions. The equation provides a straightforward way to determine the material’s ability to conduct heat, making the heat flow meter a powerful tool for evaluating thermal properties in insulating materials.

Instrument Introduction

The HFM 510A heat flow meter is a sophisticated instrument designed for precise measurement of thermal conductivity in low thermal conductivity materials. It adheres to international standards such as GB/T 10295, ASTM C518, and ISO 8301, making it suitable for a wide range of applications. This device is capable of testing materials like expanded polystyrene, extruded polystyrene, PU rigid foam, mineral wool, expanded perlite, foam glass, natural fiber materials, cork, wool, aerogel, concrete, and gypsum.

Highly Integrated Automation Functions

The HFM 510A boasts a high level of automation, significantly reducing the need for manual intervention. It features automated functions such as raising and lowering the heating plates, applying the necessary force, measuring the sample thickness, controlling the temperature, and opening or closing the furnace door. This comprehensive automation ensures consistent and accurate measurements while enhancing user convenience and efficiency.

Adaptive to Uneven Surfaces

One of the standout features of the HFM 510A is its ability to handle samples with uneven surfaces. It is equipped with advanced distance sensors and tilt sensors that measure the sample thickness with an accuracy of up to 0.02mm. This adaptability ensures precise measurements even when the sample surface is not perfectly flat, expanding the range of materials that can be tested accurately.

Three Experimental Modes

The HFM 510A offers three distinct experimental modes to cater to different testing requirements. The standard mode is designed for routine measurements with high precision, the fast mode provides quicker results for less demanding applications, and the custom mode allows users to tailor the testing parameters to specific needs. This versatility ensures that the instrument can meet various precision and duration requirements.

Extended Thermal Conductivity Measurement

The HFM 510A can measure thermal conductivity over an extended range, from 0.002W/(m·K) to 1W/(m·K), and can be scaled up to 2W/(m·K). This wide range of measurement capabilities makes it suitable for a diverse array of materials. Additionally, the instrument supports offline operation, providing flexibility in conducting experiments without the need for constant supervision.

Rich Peripheral Interfaces

This instrument includes a built-in industrial computer, eliminating the need for an external computer. It supports various peripherals such as a mouse, keyboard, and printer, enhancing connectivity and usability. These interfaces allow for easy data entry, manipulation, and printing of results, facilitating seamless integration into existing workflows.

Intelligent Data Management

The HFM 510A features intelligent data management capabilities, including optional user login for secure access, real-time monitoring of process data, and support for historical record queries. Users can filter data by date and export custom data sets, making data analysis and reporting straightforward and efficient. This robust data management system ensures that all relevant information is easily accessible and well-organized.

Specifications

The HFM 510A operates in environments ranging from -5°C to 45°C with humidity levels below 95%. The plate temperature range is from -30°C to 90°C, controlled by a Peltier system with more than 10 set points. It accommodates sample sizes up to 300mm in length and width, with heights up to 100mm. The thermal resistance range is from 0.1m²·K/W to 8m²·K/W, with a thermal conductivity range from 0.002W/(m·K) to 1W/(m·K), scalable to 2W/(m·K). The instrument boasts an accuracy of ±1% to 2% and repeatability of 0.5%. It can apply a variable load force of 21kPa (1930N) and measures thickness with a resolution of 0.02mm.

Experimental Steps

Sample Preparation

Begin by preparing the samples to be tested. For solid block samples, ensure they are cut to dimensions not exceeding 300mm x 300mm x 100mm. If using powder samples, pre-form them into a solid block using appropriate molds to fit within the device’s chamber. Proper sample preparation is crucial for accurate and consistent measurement results.

Parameter Setting

Next, set the experimental parameters. This includes specifying the standby temperature and the measurement points according to the material’s properties and desired outcomes. Choose the appropriate experimental mode—standard, fast, or custom—based on the precision and duration requirements. Note that only one mode can be selected per experiment, so choose carefully based on the specific testing needs.

Sample Placement

Carefully place the prepared sample in the furnace chamber. Ensure the sample sits smoothly and evenly to prevent any air gaps that could affect the measurement. Once the sample is in position, lower the top plate to make contact with the sample. Then, securely close the furnace chamber to maintain the internal environment and prevent heat loss during the experiment.

End of Experiment

At the conclusion of the experiment, the system will automatically display the results and relevant test information. The results are presented in a data table and accompanied by a line graph for visual representation. This comprehensive output allows for easy analysis and interpretation of the material’s thermal properties, facilitating further research or quality control processes.

Closing Thoughts

The HFM 510A Heat Flow Meter Analyzer offers a sophisticated solution for accurate thermal analysis. Its advanced automation, adaptability to uneven surfaces, and versatile experimental modes make it suitable for a wide range of materials and applications. The extended measurement range and rich peripheral interfaces enhance its functionality, while the intelligent data management system ensures efficient and secure handling of experimental data. By following precise experimental steps, users can obtain reliable and detailed thermal conductivity results, supporting research, development, and quality control processes across various industries. The HFM 510A stands out as a robust and reliable instrument for precise thermal analysis.