Understanding Powder Explosions and Their Prevention

Powder explosions are a serious safety concern in various industries that handle combustible dust. These explosions can have devastating consequences if not properly mitigated, and understanding their causes and prevention methods is critical to ensure safe working environments. This blog will explore the mechanics of powder explosions, essential testing methods, and prevention measures, providing a comprehensive guide on how to address this hazard effectively.

What is a Powder Explosion?

Causes of Powder Explosions

In many manufacturing and processing industries, the dust generated during operations is often combustible. When this combustible dust is suspended in the air in a concentration high enough to support flame propagation, and an ignition source provides enough energy, a dust explosion can occur. The result is an explosive release of energy that can cause significant damage to equipment, buildings, and personnel.

Five Key Elements of a Powder Explosion

Five essential elements must be present for a combustible dust explosion to occur:

Fuel – The combustible dust itself acts as the fuel.

Oxidant – Typically, the oxygen in the air serves as the oxidizer.

Ignition Source – A heat source with sufficient energy to ignite the dust cloud.

Suspension – The combustible dust must be suspended in the air or mixed with air above its lower explosive limit (LEL).

Confined Space – The explosion must occur in an enclosed or confined space for pressure to build and cause a violent explosion.

If all five of these factors are in place, a combustible dust cloud, when ignited, can cause an explosion. Without a confined space, the situation may result in a flash fire, but if containment is present, the expanding gases from the burning dust-air mixture can result in an increase in pressure, leading to a powerful explosion. Powder explosions are known for their high temperatures, prolonged duration, and destructive force, making them a significant industrial hazard.

Testing Combustible Dust: The Key to Safety

Why Is Combustible Dust Explosion Testing Crucial?

To mitigate the risk of powder explosions, understanding the explosion characteristics of the dust being handled is critical. Testing for explosive potential allows industries to implement effective prevention and protection measures. Various testing methods are employed to evaluate the potential for dust explosions, including those that assess both the intensity and the likelihood of such events.

Combustible Dust Explosion Testing: Assessing Explosion Intensity

One of the key tests to assess the intensity of a powder explosion is to measure the maximum explosion pressure, the maximum rate of pressure rise, and to calculate the dust cloud’s explosion severity value (Kst). The Kst value is crucial as it reflects the potential violence of an explosion for different dust types.

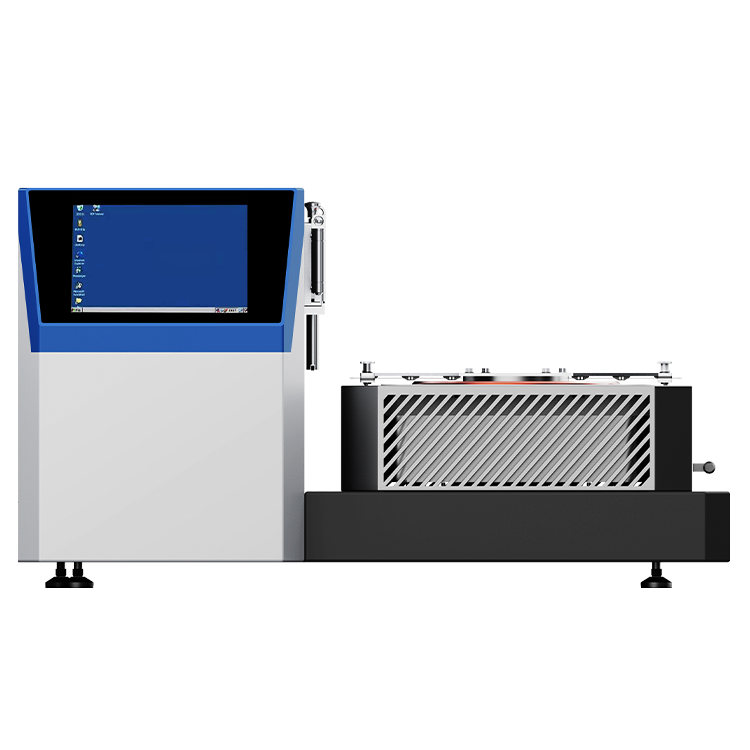

The 20L Spherical Explosion Tester is a professional instrument used for these measurements under specific test conditions. It is commonly applied in industries that handle materials like aluminum powder, plastic powder, sawdust, wheat powder, and other combustible substances.

Features of the 20L Spherical Explosion Tester:

Built-in international standards: The device supports standardized testing parameters and allows for customized test settings.

Dual ignition options: It offers both chemical ignition and electrostatic ignition for different testing purposes.

Real-time data display: Time-pressure curves are displayed in real-time for a detailed analysis of the explosion process.

Safety features: The system is equipped with remote control and automatic cleaning, ensuring the safety of the personnel during testing.

This tool provides valuable insights into the explosive behavior of dust clouds, guiding the design of protective measures such as explosion vents, suppression systems, and explosion isolation.

Combustible Dust Explosion Testing: Assessing Explosion Likelihood

While intensity is important, it is equally crucial to assess the likelihood of an explosion. The Minimum Ignition Energy (MIE) Test is used to determine the smallest amount of energy needed to ignite a dust cloud. The test evaluates how sensitive a dust cloud is to ignition sources like electrostatic or friction sparks.

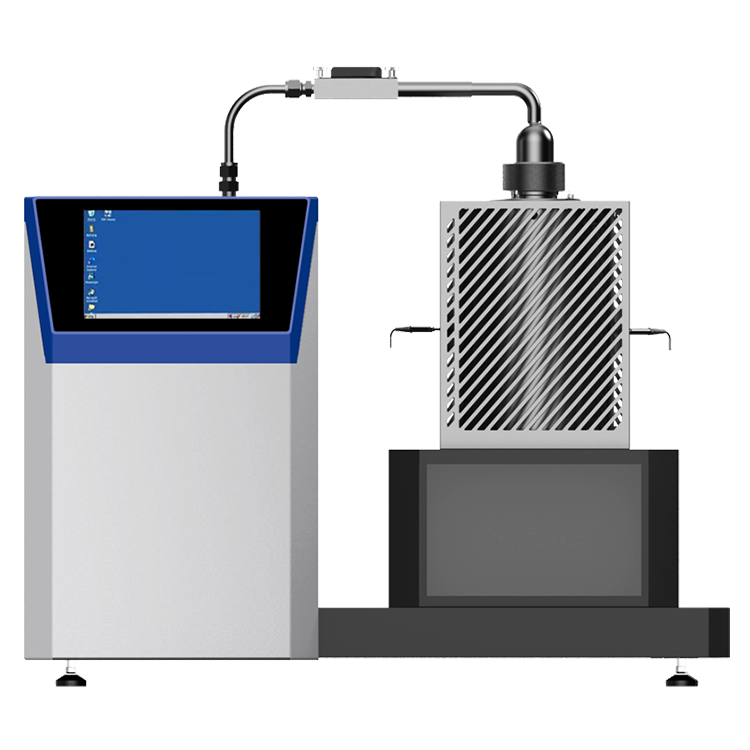

The Dust Cloud Minimum Ignition Energy Tester (MIE-3000AE) is a specialized device used to measure the MIE of different dust types. The instrument disperses a specific mass of dust into a tube using compressed air, forming a dust cloud. The cloud is then ignited with varying spark energies to find the dust’s ignition threshold.

Features of the MIE-3000AE

Automatic ignition energy selection: The device automatically selects the best capacitor and voltage combination based on the desired ignition energy.

Safety-enhancing design: It includes features such as automatic high-voltage disconnection and remote control ignition to ensure operator safety.

Customizable settings: The instrument allows for adjustments in the electrode distance, powder pressure, and ignition delay to accommodate different test requirements.

By measuring the MIE, industries can better understand the sensitivity of the dust to ignition, providing essential information for designing explosion prevention systems.

Limiting Oxygen Concentration: A Critical Safety Measure

Another critical factor in preventing dust explosions is controlling the oxygen concentration in the environment. The Limiting Oxygen Concentration (LOC) test determines the minimum oxygen level needed to sustain combustion. If the oxygen concentration is below the LOC, combustion—and thus an explosion—cannot occur. This information is used to design inert gas protection systems that keep the oxygen level in processing environments below the LOC, significantly reducing the explosion risk.

The Explosion Range Tester (HWP21-30SE) is designed to assess the combustion hazards of gases and flammable vapors. It determines the upper and lower limits (UFL and LFL) for various gas-air mixtures. Helping the industry set safe operating parameters.

Features of the Explosion Range Tester:

Temperature control: The device incorporates heating and cooling elements to maintain a stable test environment.

Pressure and temperature sensors: High-precision sensors ensure accurate readings and control over the gas concentration during testing.

Enhanced safety: The device is equipped with a pressure relief door, an interlocking mechanism, and a video monitoring system. Ensure safe and reliable operation.

By testing the LOC, the industry can implement an inert gas system that ensures oxygen levels remain low enough to prevent explosions. This provides a critical line of defense in combustible dust environments.

Conclusion

Powder explosions are a significant hazard in industries that handle combustible dust. By understanding the five fundamental elements of powder explosions – fuel, oxidizer, ignition source, suspension, and confined space. Industry can better identify risks and implement necessary safety measures. Explosion Strength (Kst), Ignition Sensitivity (MIE) and Limiting Oxygen Concentration (LOC) testing provide valuable data for designing effective explosion prevention and protection systems.

Innovative instruments such as the 20L Sphere Explosion Tester, Dust Cloud Minimum Ignition Energy Tester, and Explosion Range Tester are essential tools in the fight against dust explosions. These devices enable the industry to accurately assess its risks and implement protective measures. To protect equipment, facilities, and most importantly, human life.

By prioritizing explosion prevention and regularly testing for combustible dust, industries can significantly reduce the risk of devastating powder explosions. Creating a safer workplace for everyone.