Differential Scanning Calorimetry Equipment: Key to Understanding Material Properties

Have you ever considered how researchers pinpoint the exact melting point of a newly formulated polymer or measure the thermal stability of pharmaceutical compounds? Or perhaps wondered how these materials are rigorously examined to ensure that they perform reliably under real-world conditions? The answer lies in a refined and powerful technique known as Differential Scanning Calorimetry Equipment. This advanced method has transformed industries like pharmaceuticals, materials science, and electronics by revealing crucial insights into the intricate thermal behaviors of diverse materials. Let’s take a closer look at what Differential Scanning Calorimetry Equipment entails and explore how it operates to reveal a wealth of critical data.

Understanding Differential Scanning Calorimetry Equipment

This is a widely used method in thermal analysis. It aims to accurately measure the change in heat capacity of a material during a controlled heating or cooling process. Through this method, researchers can evaluate a variety of important thermal properties, including melting point, crystallization pattern and glass transition temperature.

At the core of it is the comparison of heat flow between a sample and a reference, both subjected to a controlled temperature program. By continuously monitoring the difference in heat flow, thermodynamic and kinetic data is gathered, deepening the understanding of how materials respond to different thermal environments. This information is represented as a Differential Scanning Calorimetry Equipment curve, which graphs heat flow in relation to temperature or time, offering insights into a material’s fundamental properties.

The Mechanics of Differential Scanning Calorimetry Equipment: How It Functions

In a standard Differential Scanning Calorimetry Equipment experiment, the sample and reference material are placed in specialized crucibles and then exposed to a constant heating or cooling rate, following a pre-set temperature schedule. A highly sensitive sensor measures the difference in heat flow between the two. Because both the sample and reference are subjected to the same temperature program, direct comparison becomes possible.

As the sample undergoes thermal events—such as melting, crystallization, or chemical reactions—it will either absorb or release heat, which is recorded as deviations in heat flow. The collected data reveals key attributes of the material, including:

- Melting and crystallization behaviors

- Glass transition temperature (Tg)

- Thermal stability and degradation patterns

- Enthalpy changes and reaction kinetics

For instance, when a polymer melts, it absorbs heat, generating an endothermic peak on the Differential Scanning Calorimetry Equipment curve. Conversely, as the polymer cools and crystallizes, heat is released, producing an exothermic peak that signals energy release.

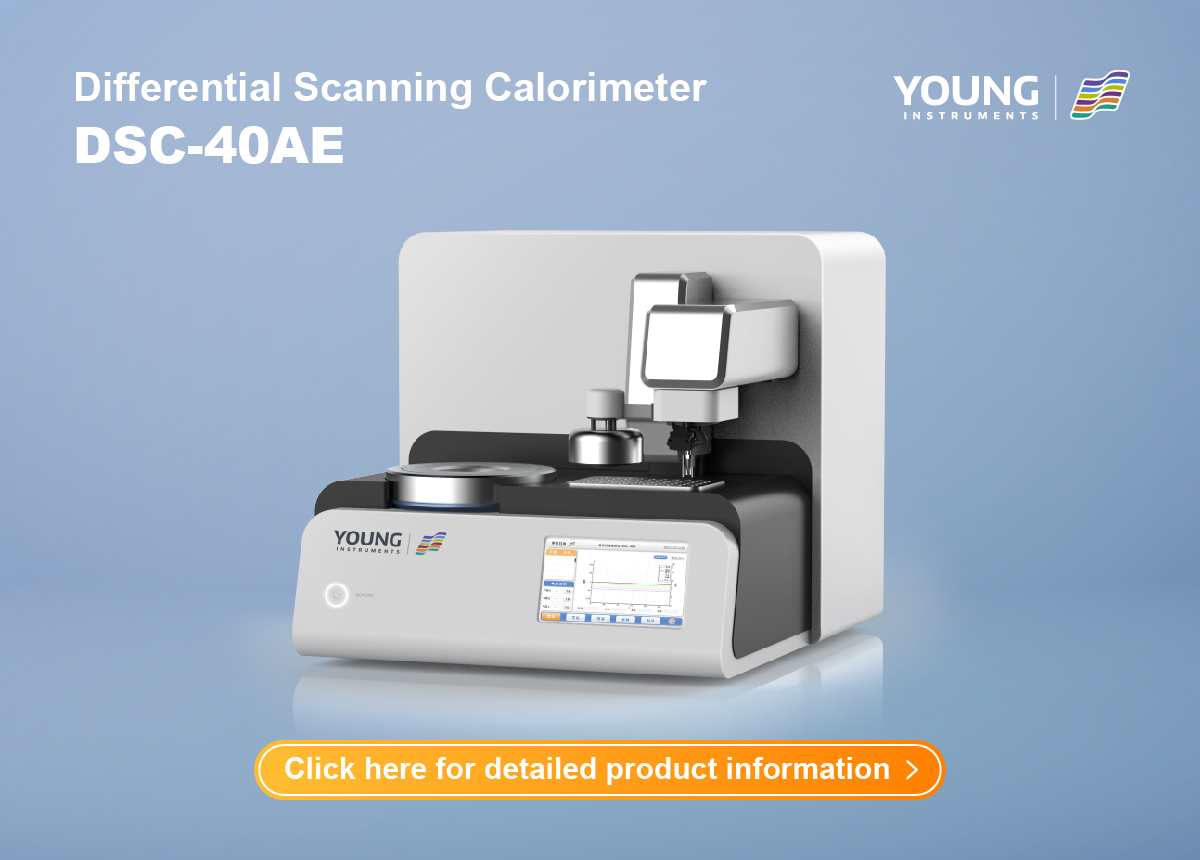

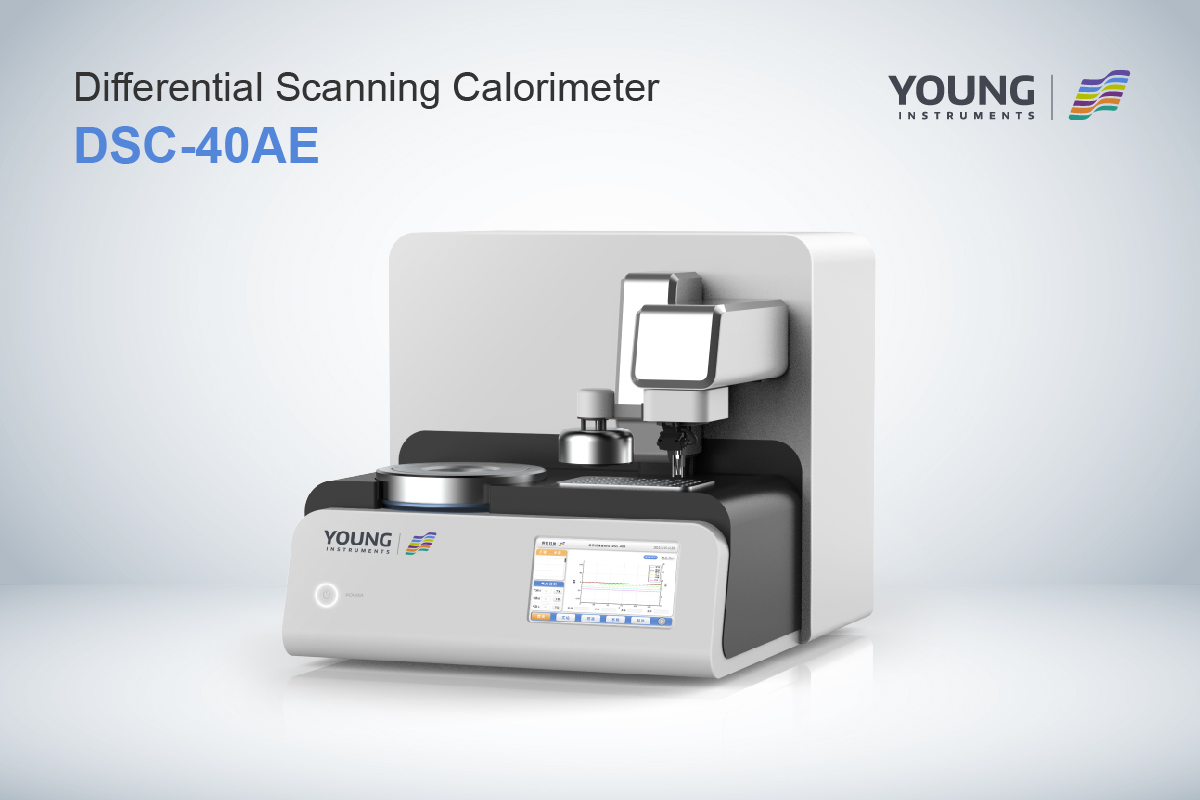

The Differential Scanning Calorimetry Equipment-40AE: A High-Performance Thermal Analysis Solution

One of the most advanced Differential Scanning Calorimetry Equipment models on the market, the Differential Scanning Calorimetry Equipment-40AE from Hangzhou Zeal Instruments Science & Technology Co., Ltd., offers cutting-edge capabilities. Built on the tower-type heat flow method, this instrument delivers accurate and reliable measurements by detecting the difference in heat flow between a sample and a reference under meticulously controlled conditions.

Several features make the Differential Scanning Calorimetry Equipment-40AE exceptional:

- High Sensitivity: Detects even minute changes in heat flow, ensuring precision.

- Excellent Reproducibility: Delivers consistent results across multiple runs, ideal for research and industrial applications.

- Stable Baseline: Reduces error, guaranteeing accuracy over time.

- Versatility: Adaptable across numerous fields, including polymers, biomedicine, and electronics.

These strengths position the Differential Scanning Calorimetry Equipment-40AE as a preferred choice among researchers and professionals seeking robust and efficient thermal analysis tools.

Differential Scanning Calorimetry Equipment’s Role Across Modern Industries

With its exceptional precision and flexibility, Differential Scanning Calorimetry Equipment has become invaluable in fields as diverse as pharmaceuticals, materials science, biomedicine, and electronics. Here, we examine how Differential Scanning Calorimetry Equipment applications vary across different sectors.

Polymers and Composite Materials

In polymer industries, it is essential for examining thermal properties like melting points, glass transition temperatures, and crystallization behaviors. By using Differential Scanning Calorimetry Equipment data, manufacturers can enhance and refine polymer processing and performance for use in everything from plastics to fibers.

When it comes to composite materials—which blend two or more substances to achieve specific chemical and physical properties—Differential Scanning Calorimetry Equipment is a powerful asset. It aids in monitoring curing processes, assessing thermal expansion, and stabilizing these multi-phase materials to ensure they meet operational demands under a range of conditions.

Biomedicine and Pharmaceuticals

In the pharmaceutical sector, Differential Scanning Calorimetry Equipment offers deep insights into the thermal behavior of drugs, excipients, and formulations. This data is essential for evaluating the stability and compatibility of pharmaceuticals during production and storage.

For instance, it is often used to determine melting points and glass transition temperatures of pharmaceutical compounds—vital indicators of purity and shelf life. Differential Scanning Calorimetry Equipment also facilitates the study of polymorphism, or the existence of multiple crystalline forms of the same compound, which is crucial for ensuring consistency in drug formulation. Additionally, Differential Scanning Calorimetry Equipment is vital in assessing thermal stability, a key factor in preserving the efficacy and safety of drugs over time.

Electronics and Energy Storage

In electronics, Differential Scanning Calorimetry Equipment assesses the thermal properties of materials used in crucial components like printed circuit boards (PCBs), displays, and batteries. Understanding these properties is fundamental for thermal management, which helps ensure product longevity and efficiency.

For example, Differential Scanning Calorimetry Equipment can determine the melting points of soldering materials, assess the thermal conductivity of heat management substances, and evaluate the thermal stability of energy storage materials, such as lithium-ion batteries. By providing precise data, Differential Scanning Calorimetry Equipment significantly contributes to enhancing the reliability, safety, and performance of electronic devices.

Conclusion: Differential Scanning Calorimetry Equipment’s Essential Role in Advancing Science and Industry

It has become essential in both scientific research and industry. By offering precise insights into thermal properties, it supports process optimization, ensures product quality, and enables the development of advanced materials across various fields, from pharmaceuticals to electronics.

The Differential Scanning Calorimetry Equipment-40AE by Hangzhou Zeal Instruments Science & Technology Co., Ltd. exemplifies the advanced capabilities of modern Differential Scanning Calorimetry Equipment equipment. With its high sensitivity, reproducibility, and adaptability, this instrument is an invaluable asset for laboratories and industries needing reliable thermal analysis.

As technology and materials science continue to advance, its role in understanding and controlling material properties will grow. This drives innovation and improves product performance in all areas.