ASTM E711: Unlocking Precision in Calorific Value Testing for a Greener Future

Why measuring energy content is essential? ASTM E711 is a standard test method specifically designed to measure the calorific value of fuels, indicating the amount of energy a material releases when burned. This procedure is extensively used across various industries dependent on fuel for energy generation.

Understanding ASTM E711

Definition and Scope of the Standard

ASTM E711 is a standard test method for measuring the energy content of fuels. It helps determine how much energy a material releases when burned. This method is widely used in different industries, including power generation and manufacturing. It ensures that fuel quality is tested accurately and consistently.

Why is this standard important? It provides a reliable way to compare different types of fuel. This helps industries choose the best energy sources. Without proper testing, energy production may become inefficient. This could lead to unnecessary waste and higher costs.

Key Principles of the Testing Method

The testing method in ASTM E711 measures the calorific value of fuels using a controlled combustion process. The sample is placed in a sealed chamber with pure oxygen. Then, it is ignited, and the heat released is measured. This gives the exact energy content of the material.

Why is this method used? It ensures that all fuel samples are tested under the same conditions. This provides accurate and repeatable results. The data helps industries make better energy decisions. Without this, fuel efficiency may vary, leading to unexpected energy losses.

Zeal Instruments’ Oxygen Bomb Calorimeter

The ATC 300A Oxygen Bomb Calorimeter follows ASTM E711 standards. It measures the calorific value of different fuels quickly and precisely. It has an advanced temperature control system. This ensures stable and accurate results every time.

Why is this device useful? It allows industries to perform reliable fuel testing. This helps improve energy efficiency. It also supports environmental protection by reducing waste. Many industries rely on this device for critical measurements.

Advancements in Testing Technology

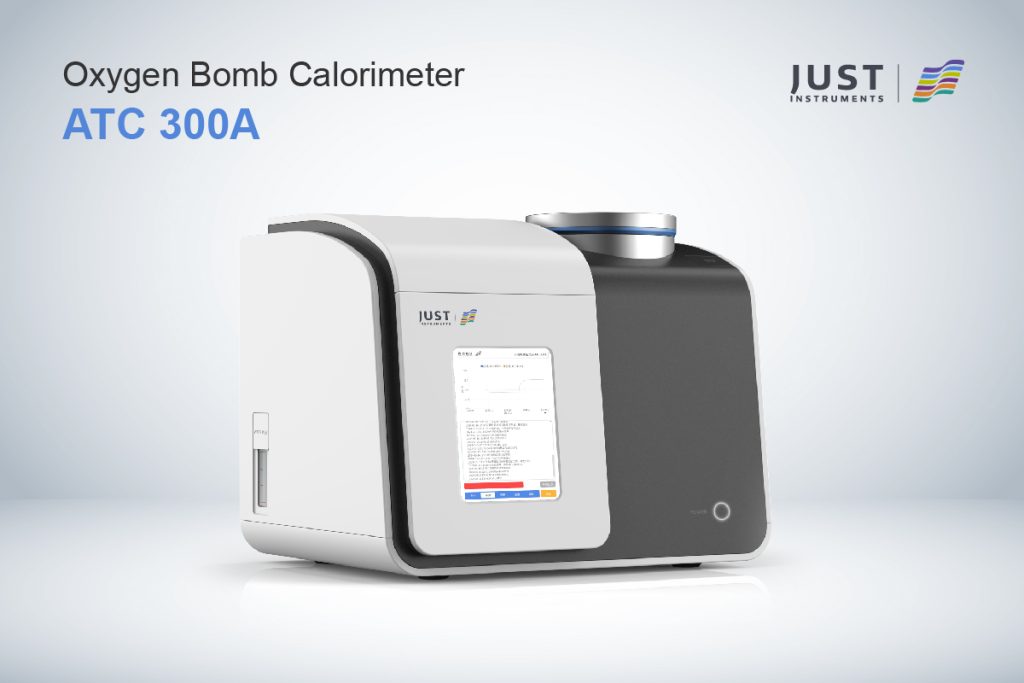

Enhancing Accuracy in Fuel Testing with ATC 300A

The ATC 300A Oxygen Bomb Calorimeter is designed for precise fuel energy measurement. It follows the ASTM E711 standard, ensuring high accuracy and reliability. The device operates within 15°C to 30°C and can handle up to 80% humidity without condensation. With a temperature resolution of 0.0001°C, it captures even the smallest changes in heat transfer. The system automates many functions, reducing manual effort and improving efficiency.

Advanced Automation for Speed and Precision

The ATC 300A automates several processes. It lifts the bomb automatically, recognizes serial numbers, and fills and releases oxygen without manual input. It detects oxygen pressure and measures the water volume in the inner cylinder automatically. These features ensure fast and stable testing. The calorimeter completes tests in under 15 minutes using the conventional method and in less than 10 minutes with the rapid method.

Optimized Cooling and Stability

The device has a high-efficiency filter and a semiconductor cooling water system. It precisely controls temperature, maintaining balance through heating, insulation, and cooling. This prevents environmental interference and enhances accuracy. The system also regulates oxygen bomb pressure up to 240 bar, ensuring safe operation.

User-Friendly Interface and Intelligent Control

A touchscreen color LCD provides real-time data visualization. The advanced serial port technology allows multiple units to work simultaneously without interference. A dual control system supports both touchscreen operation and PC-based monitoring, improving usability. The device can store at least 10,000 entries, allowing users to access historical data easily.

Smart Data Processing for Reliable Results

The ATC 300A corrects test values automatically. It calculates higher heating value, lower heating value, and bomb calorific value while adjusting for factors like ignition wire combustion, nitric acid formation, sulfur content, and hydrocarbons. The system ensures precision within 0.10% and keeps calorific fluctuation below 0.20%. Automated data collection and chart generation simplify analysis and improve efficiency.

The Role of Calorific Value Testing

Why Accurate Energy Measurement Matters

Accurate calorific value measurement is important for energy management. It helps industries optimize fuel use and control costs. If energy content is not measured properly, fuel may be wasted. This can lead to higher expenses and lower efficiency.

Why does this matter? Understanding the energy content of fuels helps industries make better choices. It also helps reduce pollution by ensuring complete combustion. Without proper testing, energy use may become inefficient, affecting both businesses and the environment.

Impact on Fuel Efficiency and Emissions Reduction

Calorific value testing helps improve fuel efficiency. It ensures that industries use the right amount of fuel. This prevents energy waste and lowers costs. In addition, it helps control emissions by ensuring complete combustion.

How does this help the environment? Incomplete combustion produces harmful gases. These gases contribute to air pollution and climate change. By measuring calorific value accurately, industries can adjust combustion settings. This reduces emissions and supports clean energy use.

Significance and Applications

Calorific value testing is used in many industries. It helps improve fuel efficiency, reduce costs, and protect the environment. Here are some key benefits:

- Optimizing Energy Utilization

Accurate calorific value measurement helps manage fuel efficiently. This reduces waste and improves energy use. Many industries, such as power plants and factories, depend on this process.

- Enhancing Combustion Efficiency

Different fuels burn differently. By knowing the calorific value, industries can adjust combustion settings. This ensures complete combustion. It also reduces unburned residues and lowers emissions.

- Ensuring Safety in Production

Some industries use fuels in high-temperature environments. If the calorific value is too high, it may cause overheating. This can lead to equipment damage or explosions. By monitoring calorific value in real time, industries can prevent accidents.

- Supporting Environmental Policies

Governments set rules for energy use and emissions. Calorific value testing helps businesses follow these regulations. It also helps them reduce their carbon footprint. By using this method, industries can support sustainability and cleaner energy solutions.

Instrument Application Value

Fuel Quality and Power Plant Efficiency

The ATC 300A ensures that fuels meet quality standards. It helps industries optimize combustion efficiency. In power plants, it measures the calorific value of fuels. This allows operators to adjust combustion parameters, improving energy production and reducing waste.

Heat Management and Product Quality

In chemical reactions, heat release must be monitored. The calorimeter helps prevent overheating and ensures safety. It also supports product quality control. Many chemical products require precise energy content to meet performance standards.

Emissions Control and Carbon Accounting

Combustion processes release pollutants. The ATC 300A measures exhaust gas composition and calorific value. This helps industries reduce emissions. It also calculates carbon emissions based on fuel properties. Businesses can use this data to meet environmental regulations.

Scientific Research and Education

Researchers use the device to study energy materials and combustion. It helps develop high-efficiency fuels. It is also a valuable teaching tool in physical chemistry and thermodynamics. Students learn about energy conversion through hands-on experiments.

Enhance Energy Efficiency with the ATC 300A

The ATC 300A helps industries test fuel quality. It ensures fuels meet standards. It improves combustion efficiency. Power plants use it to measure fuel energy. Operators adjust settings for better performance. This reduces waste and saves costs. Get more information with us now!