Meet the DSC Testing Machine – The Gateway to Thermal Analysis Excellence!

The Differential Scanning Calorimetry (DSC) Testing Machine is a powerful tool for analyzing how materials respond to temperature changes. By measuring heat flow, it helps scientists and engineers understand phase transitions, stability, and thermal properties.

Why does this matter? Many industries rely on DSC to assess material behavior under varying conditions. Plastics, metals, and pharmaceuticals all react differently to heat, making thermal analysis essential for ensuring quality, stability, and performance.

Widely used in research and manufacturing, the DSC machine plays a vital role in material science and thermal analysis. Curious about how it works?

What is a DSC Testing Machine?

A Differential Scanning Calorimetry (DSC) Testing Machine is a tool that measures how a material reacts to heat. It helps scientists and engineers study thermal properties. Many industries use it to test materials like plastics, metals, and medicines. It is useful because it shows changes in heat flow when a material is heated or cooled. This helps in research, quality control, and product development.

Main Parts of a DSC Testing Machine

A DSC machine has several important parts. Each part plays a key role in the testing process.

- Temperature Control System – It controls how fast the machine heats or cools. This ensures accurate test conditions.

- Heating Furnace – It provides a steady heat source for both the sample and the reference material.

- Sample Cell – It holds the material being tested.

- Reference Cell – It contains a stable material for comparison.

- Heat Flow Sensor – It measures the heat difference between the sample and the reference. It converts this data into an electrical signal.

- Data Processing System – It collects and analyzes the signals. It then displays the results as a graph.

Each part works together to ensure precise measurements.

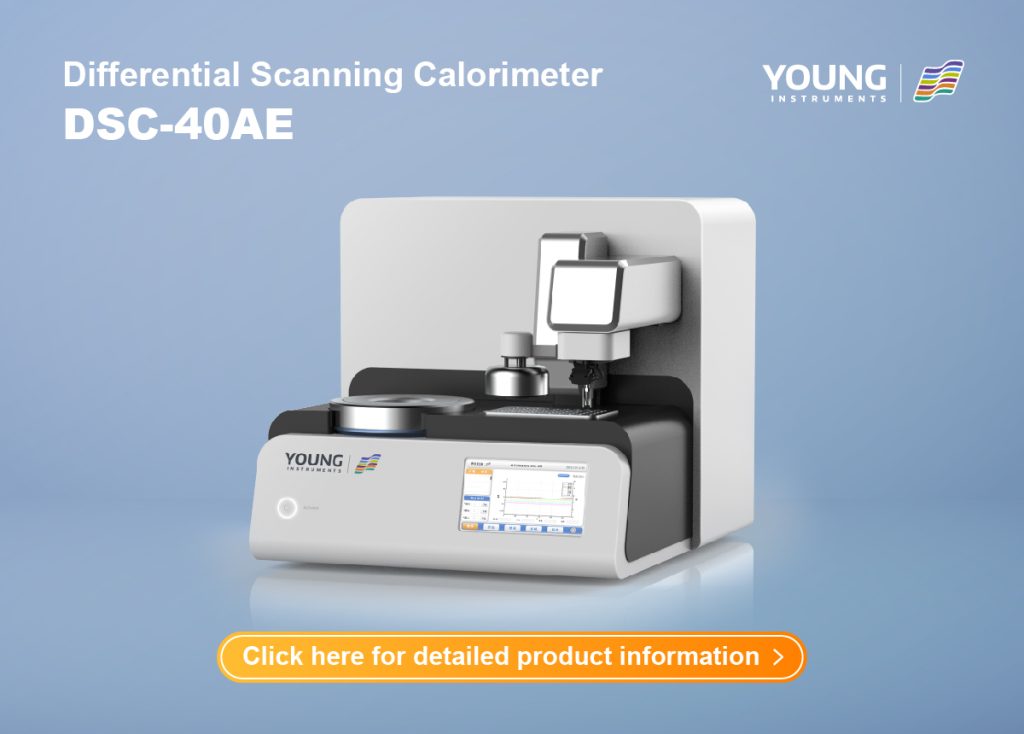

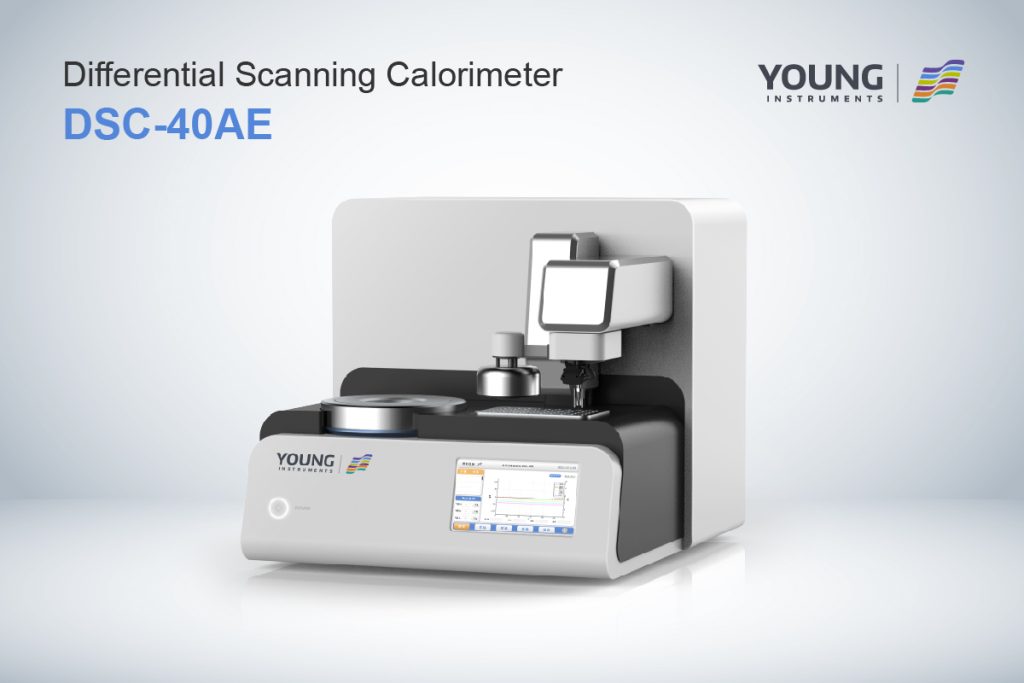

Zeal Instruments’ DSC Testing Machine: Features & Advantages

Advanced Heat Flow Technology

The DSC-40AE is a high-precision thermal analysis instrument. It uses a tower-type heat flow method to measure heat flow differences between a sample and a reference. This allows accurate testing of material properties as temperature changes over time. It can operate within a temperature range of RT to 600°C, making it suitable for a wide range of materials.

High Sensitivity and Accurate Measurements

This machine features advanced algorithms that precisely control temperature and heat flow. It accurately measures specific heat capacity, exothermic reactions, phase transitions, and enthalpy changes. The Nickel-chromium substrate improves oxidation resistance and enhances sensitivity. The data acquisition rate of 50Hz ensures high resolution and reliable results.

Optimized Design for Efficiency

The silver furnace body improves heat transfer efficiency and reduces interference between the sample and reference. It supports both ramp and isothermal temperature control modes, providing flexibility in experiments. The high-definition touchscreen makes operation simple and user-friendly.

Superior Performance and Stability

The heating scan rate ranges from 0.1K/min to 200K/min, allowing precise control. It has phase transition temperature accuracy of ±0.02K and enthalpy accuracy of ±1%. The baseline reproducibility is under 15μW, ensuring stability. The heat flow display resolution of 0.1μW and low peak noise of 9μW enhance measurement precision.

Types of DSC Machines

DSC machines are grouped into two main types based on how they work.

Power Compensation DSC

- It has two separate heating elements. One heats the sample, and the other heats the reference.

- It adjusts the heating power to keep both at the same temperature.

- It provides highly accurate results. It can detect small heat changes.

- It is best for detailed studies, such as medicine research and complex polymer analysis.

Heat Flow DSC

- It uses a single heat source for both the sample and the reference.

- It measures the difference in heat flow between them.

- It has a simpler design and costs less than power compensation DSC.

- It is often used for routine testing, such as checking basic material properties.

Both types of DSC machines help in studying material behavior. The choice depends on the level of accuracy needed.

Why is DSC Testing Important?

A Differential Scanning Calorimetry (DSC) test helps scientists and engineers understand how materials react to heat. It measures important thermal properties. Many industries use DSC to test materials. It helps in research, product development, and quality control.

Role in Determining Material Properties

Differential Scanning Calorimetry (DSC) is crucial in analyzing material properties under heat exposure.

- Melting Point: Determines the temperature at which a material melts, aiding in substance identification and purity checks.

- Crystallization: Measures when a material forms a solid from a liquid, essential for plastics and metals.

- Heat Capacity: Shows how much heat a material can absorb before temperature changes, helping design heat-resistant materials.

Applications in Different Industries

DSC is widely used across industries to enhance product safety and reliability.

- Pharmaceuticals: Assesses drug stability and storage conditions, ensuring heat tolerance.

- Polymer Industry: Tests plastics and rubber for strength, flexibility, and melting behavior, ensuring safety standards.

- Food Processing: Analyzes fats and oils for freshness and quality in processed foods.

Applications of DSC Testing

A Differential Scanning Calorimetry (DSC) test helps study how materials respond to heat. Many industries use this method to test thermal properties, chemical reactions, and material stability.

Thermal Property Analysis of Materials

DSC measures important thermal properties of materials. It helps determine melting point, boiling point, crystallization temperature, and glass transition temperature. These properties are important in many industries.

In plastic manufacturing, knowing the melting and crystallization temperatures helps set the right processing conditions. In metallurgy, DSC helps in studying phase transitions in metals and alloys. In pharmaceuticals, it ensures drugs remain stable under different temperatures. DSC is useful in industries where heat affects material performance.

Chemical Reaction Studies

DSC is used to analyze how heat affects chemical reactions. It measures reaction heat and kinetics, which help in understanding energy changes during a reaction.

In chemical production, DSC helps optimize reaction conditions. This improves efficiency and ensures consistent product quality. In battery research, it helps study heat generation in lithium-ion batteries, preventing overheating risks. DSC is also used in food science to study heat-related reactions in food processing.

Material Stability Evaluation

DSC checks how stable materials are under heat. It detects decomposition, oxidation, and other reactions that may weaken materials.

In aerospace, materials must withstand extreme heat and pressure. DSC helps ensure they remain stable. In electronics, it tests components like circuit boards and semiconductors to prevent failure under heat. In medicine, DSC helps determine the shelf life of drugs by testing their stability. DSC is important in industries where heat can affect safety and performance.

Sample Requirements for DSC Testing

For accurate DSC results, samples must meet specific requirements. Proper sample selection ensures reliable and repeatable measurements.

Sample Purity

The sample must be high in purity because impurities can change test results. Contaminants may cause errors in measuring thermal properties like melting or crystallization points. High-purity samples ensure accurate and repeatable results.

Sample Amount

The required sample weight is usually a few milligrams to a few dozen milligrams. Too much material can lead to uneven heating, affecting accuracy. Too little material may produce weak signals, making results unreliable. Proper sample weight helps maintain precision and sensitivity.

Sample Shape & Size

Solid samples should be finely ground to allow even heating. Liquid samples should be placed evenly in the sample cell for consistent heat transfer. Proper sample preparation improves measurement precision and reliability.

DSC testing requires careful sample handling to achieve accurate and meaningful results.

Closing Words

The DSC-40AE is a cutting-edge thermal analysis machine designed for high precision in measuring heat flow. It plays a crucial role in evaluating melting behavior, crystallization, and heat capacity, delivering reliable results for both research and production.

Equipped with a tower-type heat flow system, the DSC-40AE offers enhanced sensitivity. Its advanced algorithms ensure precise temperature control, while the silver furnace body optimizes heat transfer. A high-definition touchscreen provides an intuitive user experience.

Versatile across industries, it analyzes plastics, metals, and pharmaceuticals, ensuring product stability and quality. For superior thermal analysis, trust the DSC-40AE to deliver accurate and dependable results.