Oxygen Bomb Calorimeter (ATC 300A) Designed in Accordance with ASTM D4809 Standards for Precise Combustion Heat Measurement

Calorimetry, the science of measuring heat released or absorbed during chemical reactions, plays a crucial role in various industries such as coal, metallurgy, construction, and petrochemicals. In this pursuit of accuracy, ASTM D4809 stands out as a beacon of reliability.

Understanding ASTM D4809

ASTM D4809 is a standard test method developed by the American Society for Testing and Materials (ASTM) to determine the heat of combustion of hydrocarbon fuels, specifically focusing on liquid hydrocarbon fuels. This method is particularly tailored for use with aviation turbine fuels, where precision is crucial due to safety and performance requirements.

Application of ASTM D4809:

- Aviation Industry:ASTM D4809 is extensively utilized in the aviation industry to assess the quality and performance of aviation turbine fuels. Given the stringent safety and operational standards in aviation, precise measurement of heat of combustion is essential to ensure optimal engine performance and safety during flight.

- Fuel Quality Control:Fuel manufacturers and distributors employ ASTM D4809 to verify the quality and consistency of liquid hydrocarbon fuels. By accurately measuring the heat of combustion, deviations in fuel composition and energy content can be identified, allowing for adjustments to maintain product quality and adherence to regulatory standards.

- Research and Development:Scientists and researchers utilize ASTM D4809 in the development and testing of new fuel formulations and additives. Understanding the heat of combustion helps in assessing the efficiency, environmental impact, and compatibility of alternative fuel sources, contributing to advancements in energy technology and sustainability.

- Environmental Monitoring:The heat of combustion data obtained through ASTM D4809 can also be valuable for environmental monitoring and assessment. By analyzing the combustion characteristics of different fuels, researchers can evaluate their potential impact on air quality, emissions, and climate change, aiding in the development of strategies to mitigate environmental concerns associated with fuel combustion.

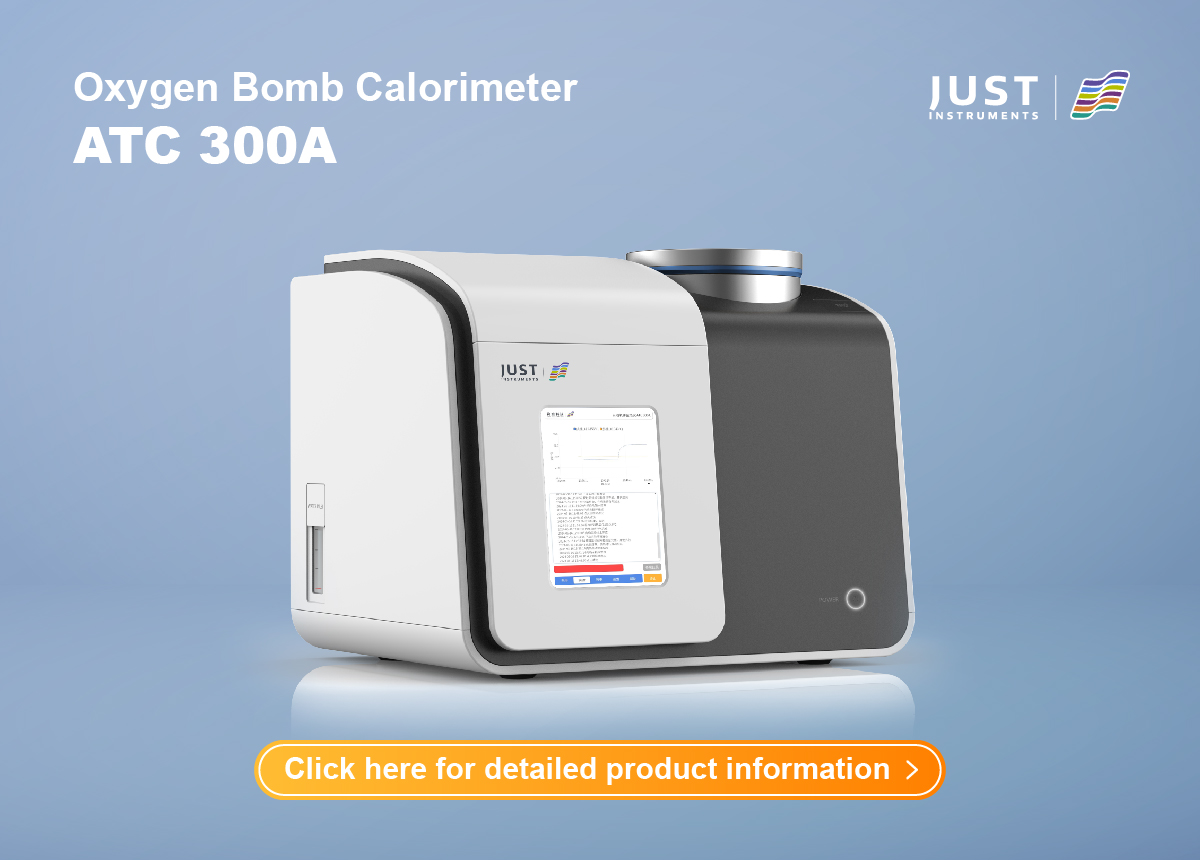

Oxygen Bomb Calorimeter (ATC 300A)

Introducing Zeal Instruments’ Oxygen Bomb Calorimeter (ATC 300A), compliant with ASTM D4809 standards. Operating between 15ºC to 30ºC with a maximum humidity of 80%, it ensures reliable results without condensation. Utilizing Cotton Thread or Ignition Wire, it offers precise ignition. With a temperature resolution of 0.0001℃ and Isoperibol test mode, tests are completed in under 15 minutes. Its calorific value testing range extends up to ≤34000J with a precision of ≤0.10%. Calorific fluctuation remains ≤0.20% within one year. Constructed with stainless steel and corrosion-resistant Hastelloy, it withstands pressures of up to 240 bar. Its expansive data storage capacity accommodates ≥10,000 entries for comprehensive analysis.

1. Automatic Precision: Redefining Calorimetric Measurements

At the heart of Oxygen Bomb Calorimeter (ATC 300A) lies a suite of automatic features designed to streamline and enhance the calorimetric testing process. From automatic bomb lifting to automatic oxygen filling and release, this instrument eliminates the need for manual intervention, ensuring consistent and reliable results. The automatic bomb serial number recognition further enhances efficiency, facilitating seamless tracking and management of test data.

2. Effortless Water Management: Ensuring Accurate Results

The internal and external barrels of Oxygen Bomb Calorimeter (ATC 300A) are equipped with automatic water inlet and drainage systems, eliminating the need for manual handling. This feature not only saves time but also ensures precise control over the water volume, crucial for accurate calorimetric measurements. By automating water management, Oxygen Bomb Calorimeter (ATC 300A) minimizes potential sources of error, guaranteeing the integrity of test results.

3. Innovative Cooling System: Achieving Thermal Equilibrium with Ease

One of the standout features of Oxygen Bomb Calorimeter (ATC 300A) is its unique semiconductor cooling water circulation system. This system, coupled with a high-efficiency filter, monitors temperature trends and controls water temperature with remarkable precision. By quickly achieving thermal equilibrium and minimizing environmental interference, Oxygen Bomb Calorimeter (ATC 300A) ensures accurate and consistent test results, even in challenging conditions.

4. Intelligent Ignition Circuit: Ensuring Safety and Reliability

Oxygen Bomb Calorimeter (ATC 300A) comes equipped with an automatic ignition wire detection and short-circuit protection system, enhancing safety and reliability during testing. This feature not only detects potential issues with the ignition circuit but also protects short circuits, safeguarding the integrity of experiments and minimizing downtime.

5. Intuitive Interface: Enhancing User Experience

The inclusion of a touchscreen color LCD in Oxygen Bomb Calorimeter (ATC 300A) revolutionizes the user experience, making the testing process more intuitive and user-friendly. With stable software operation and real-time data curve display, users can monitor experiments with ease, gaining valuable insights into calorimetric measurements in real-time.

6. Automatic Data Correction: Ensuring Accuracy in Results

Oxygen Bomb Calorimeter (ATC 300A) offers automatic data correction, providing three calorific values: higher heating value, lower heating value, and bomb calorific value. By correcting for factors such as the heat produced by ignition wire combustion and the calorific value of specific substances, Oxygen Bomb Calorimeter (ATC 300A) ensures the accuracy and reliability of test results, even in the presence of potential sources of error.

7. Advanced Connectivity: Facilitating Multi-Control and Data Retrieval

With advanced serial port technology, Oxygen Bomb Calorimeter (ATC 300A) supports multi-control for multiple units, ensuring that experiments do not interfere with each other. Additionally, the instrument automatically generates and saves charts and process data, supporting historical data retrieval for further analysis and comparison.

8. Smart Interaction: Dual Control System for Enhanced Convenience

Oxygen Bomb Calorimeter (ATC 300A) features a dual control system for smart interaction, integrating a color touchscreen with a PC-based operating system. This synchronized experiment monitoring enhances safety and convenience, allowing users to interact with the instrument in a manner that best suits their preferences and workflow.

9. Standards Compliance: Meeting Industry Requirements with Precision

Oxygen Bomb Calorimeter (ATC 300A) adheres to a range of industry standards, including GB 384, GB/T 14402, GB/T 213, GB/T 30727, ASTM D4809, ASTM D240, ASTM D5865, ASTM E711, and ASTM D5468. By meeting these rigorous standards, the Oxygen Bomb Calorimeter (ATC 300A) ensures compatibility with existing protocols and facilitates seamless integration into laboratory workflows.

In Conclusion

Zeal Instruments’ ATC 300A adheres to industry testing standards such as ASTM D4809, ensuring precise and reliable data support for sectors including petroleum, food, coal, and construction materials. Its accuracy and strict adherence to standards establish it as a trusted choice for quality assessment and research across diverse industries. For any inquiries or requirements, individuals are encouraged to reach out to Zeal Instruments. The company is committed to delivering customized solutions and expert support to effectively meet the testing needs of its clientele.