ASTM E793: Standard Test Method for Enthalpies of Fusion and Crystallization of Polymers – A Comprehensive Guide

If you’re working in a field that requires the measurement of the enthalpies of fusion and crystallization, you may be familiar with ASTM E793. This standard test method outlines the procedures for determining the heat of fusion and crystallization using differential scanning calorimetry (DSC). It’s a widely used method for analyzing solid and liquid samples, and it’s an essential tool for many industries.

The scope of ASTM E793 covers the determination of enthalpy changes associated with the melting and crystallization of materials. The test method is applicable to a wide range of materials, including polymers, metals, and ceramics. The standard provides detailed instructions on how to prepare test specimens, how to perform the tests, and how to report the results. It also includes information on the precision and bias of the test method, which is essential for ensuring accurate and reliable results.

Key Takeaways

- ASTM E793 is a standard test method for determining the enthalpies of fusion and crystallization using differential scanning calorimetry (DSC).

- The scope of the standard covers a wide range of materials, and it provides detailed instructions on test specimen preparation, test procedures, and result reporting.

- The standard also includes information on the precision and bias of the test method, which is essential for ensuring accurate and reliable results.

Scope of ASTM E793

If you are working with solid or liquid samples and need to determine the enthalpy (heat) of fusion (melting) and crystallization, then ASTM E793 is the test method for you. This standard describes the procedure for measuring the enthalpy of fusion and crystallization by differential scanning calorimetry (DSC).

DSC is a thermal analysis technique that measures the amount of heat absorbed or released by a sample as it is heated or cooled. The enthalpy of fusion is the amount of heat required to melt a solid sample, while the enthalpy of crystallization is the amount of heat released when a liquid sample solidifies. By measuring these enthalpies, you can gain insights into the thermal behavior of your sample.

ASTM E793 is useful for quality control, specification acceptance, and research. It applies to solid samples in granular form or in any fabricated shape from which an appropriate specimen can be cut, or to liquid samples that crystallize upon cooling. The test method does not apply to samples that decompose or react during the temperature range of interest.

The standard specifies the equipment, test conditions, and data analysis procedures to be used for the test. It also guides the preparation and handling of the sample, as well as the calibration and verification of the DSC instrument. By following the procedures outlined in ASTM E793, you can obtain accurate and reproducible measurements of the enthalpies of fusion and crystallization for your samples.

Summary of Test Method

Principle of the Test

ASTM E793 is a test method that measures the enthalpy of fusion and crystallization of a sample using differential scanning calorimetry (DSC). The enthalpy of fusion is the amount of heat required to melt a solid, while the enthalpy of crystallization is the amount of heat released when a liquid solidifies. These values can provide important information about the thermal behavior and properties of a material.

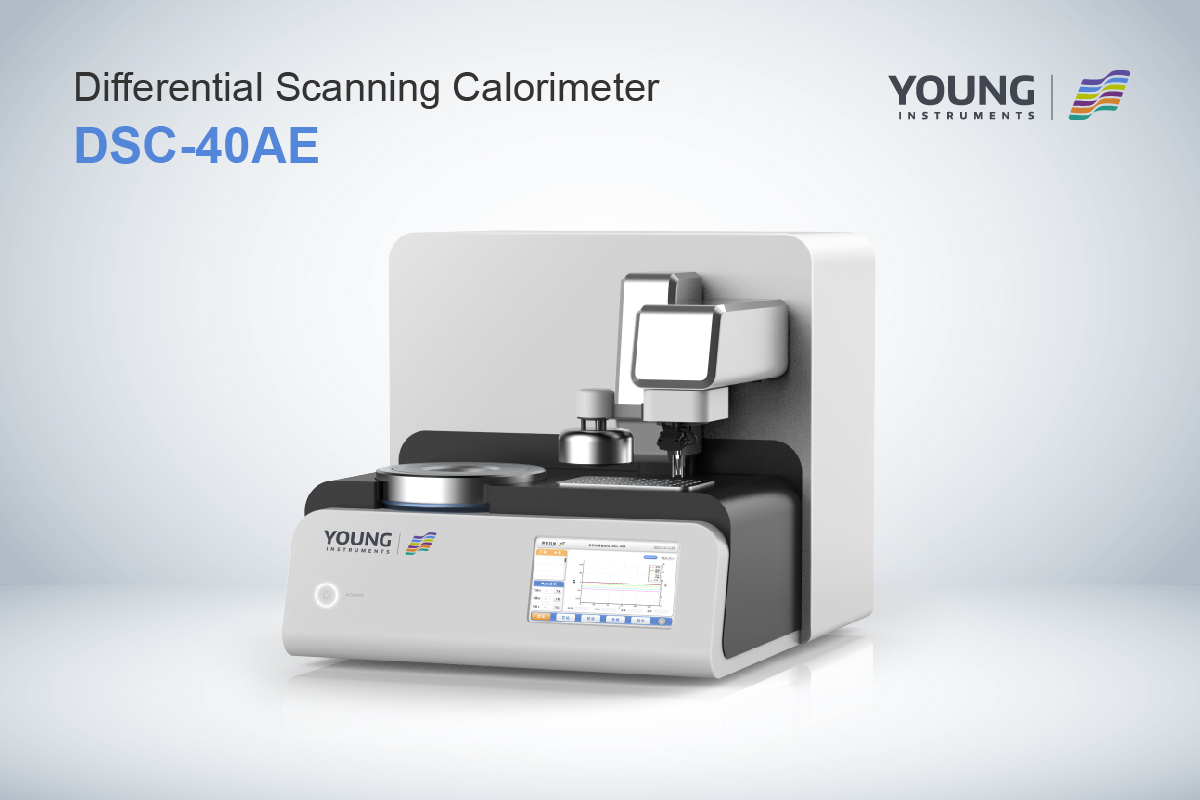

Test Apparatus

The test requires a differential scanning calorimeter, which consists of a sample holder, a reference holder, and a heating/cooling system. The sample holder contains the test specimen, while the reference holder contains an inert material that does not undergo any thermal transitions during the test. The heating/cooling system is used to control the temperature of the sample and reference holders.

Test Procedure

To perform the test, a small amount of the sample is placed in the sample holder, and the reference holder is filled with an inert material. The sample and reference holders are then heated at a constant rate, and the heat required to maintain the temperature difference between the sample and reference holders is measured. When the sample undergoes a thermal transition, such as melting or crystallization, the heat required changes, and this change is recorded. The enthalpy of fusion or crystallization is then calculated using the recorded data.

In summary, ASTM E793 is a test method that measures the enthalpy of fusion and crystallization of a sample using differential scanning calorimetry. The test requires a differential scanning calorimeter, and the enthalpy of fusion or crystallization is calculated from the recorded data.

Significance and Use

If you’re looking to determine the enthalpy (heat) of fusion (melting) and crystallization of solid or liquid samples, ASTM E793 is the standard test method you need. This method uses differential scanning calorimetry (DSC) to provide a rapid and accurate way to measure enthalpic changes accompanying first-order transitions of materials.

Differential scanning calorimetry provides a quick and efficient method for quality control, specification acceptance, and research. This test method is applicable to solid samples in granular form or in any fabricated shape from which an appropriate specimen can be cut, or to liquid samples that crystallize upon cooling.

ASTM E793 is a valuable tool for determining the thermal properties of materials, including the melting and crystallization points. It can be used for a wide range of materials, including metals, polymers, and ceramics. The enthalpy of fusion and crystallization can be used to determine the purity of a material, as well as its thermal stability and phase transitions.

Overall, ASTM E793 is a reliable and widely used test method for determining the enthalpies of fusion and crystallization of materials. It provides accurate and repeatable results, making it a valuable tool for quality control, research, and specification acceptance.

Test Specimen Preparation

Material Selection

The material selected for testing should be representative of the sample being analyzed. The ASTM E793 test method is applicable to solid samples in granular form or in any fabricated shape from which an appropriate specimen can be cut, or to liquid samples that crystallize within the range of the instrument. The material should be homogeneous, free of inclusions, and should not contain any impurities that may affect the thermal behavior of the sample.

Specimen Geometry

The geometry of the specimen can affect the accuracy of the test results. The specimen should be of uniform thickness and should have a flat and smooth surface. The thickness of the specimen should be such that the thermal conductivity of the material does not affect the accuracy of the test results. The size of the specimen should be such that it can be accommodated in the sample holder of the differential scanning calorimeter (DSC).

The specimen can be prepared by cutting it from a larger sample using a sharp blade or a cutting tool. The edges of the specimen should be smooth and free of any deformations. The specimen can also be molded into the desired shape using a mold. The mold should be made of a material that does not react with the sample or affect its thermal behavior.

It is important to note that the specimen mass to be used depends on the magnitude of the transition enthalpy and the volume of the capsule. For comparing multiple results, use similar mass (±5%) and volume of the capsule. The specimen should be weighed using a balance that is readable to 0.001 mg for test specimens on the order of 1 mg in mass to achieve the precision described in this standard.