Automatic Isoperibol Calorimeter: A Guide

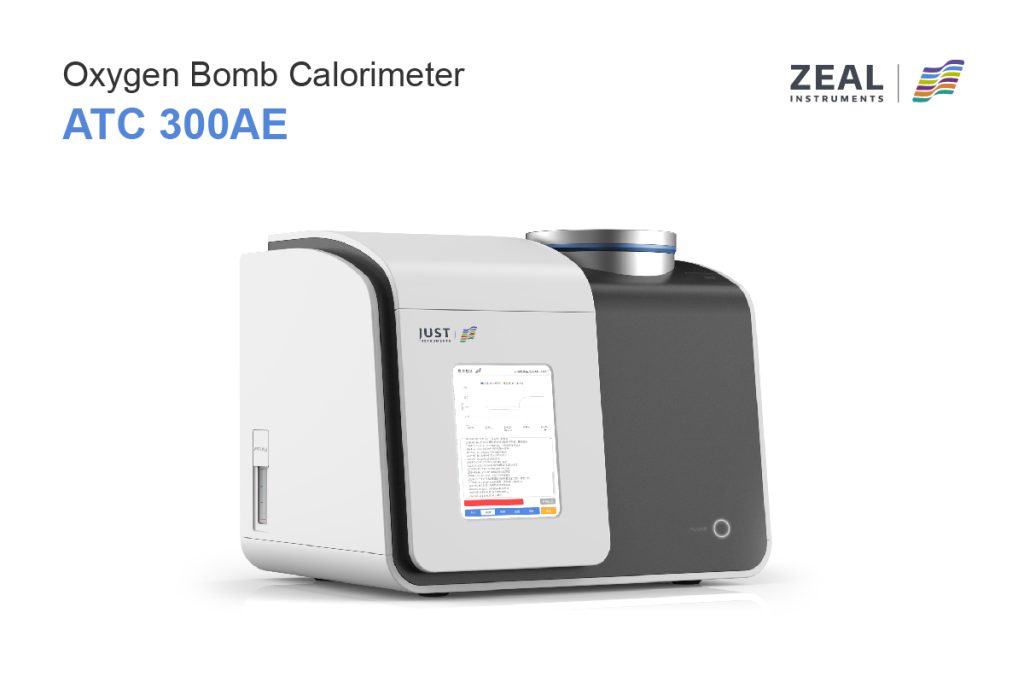

If you are conducting research on the calorific content of solid and liquid fuels, you may have come across the term “Automatic Isoperibol Calorimeter.” This instrument is widely used in laboratories to measure the calorific value of various substances. It is an advanced type of calorimeter that is designed to provide highly accurate results in a short amount of time.

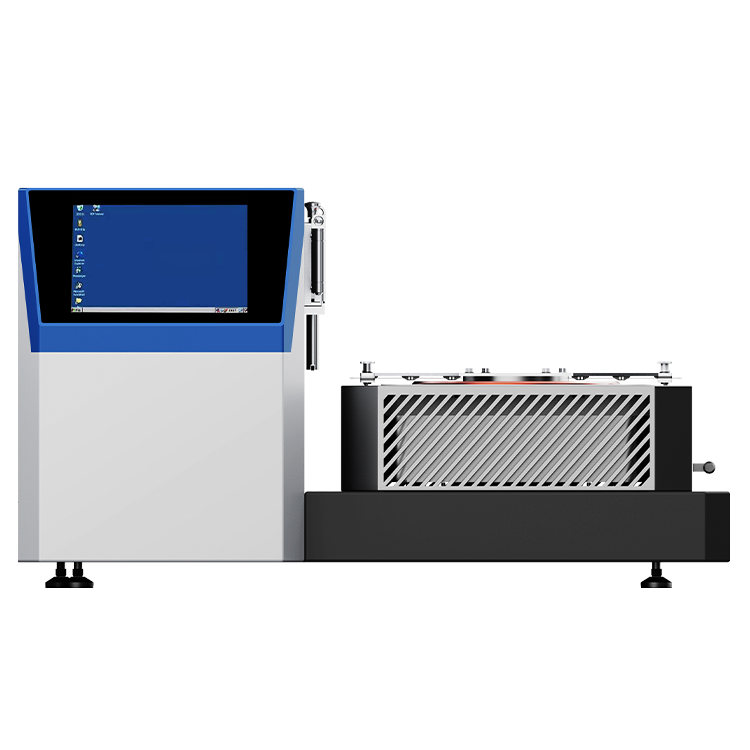

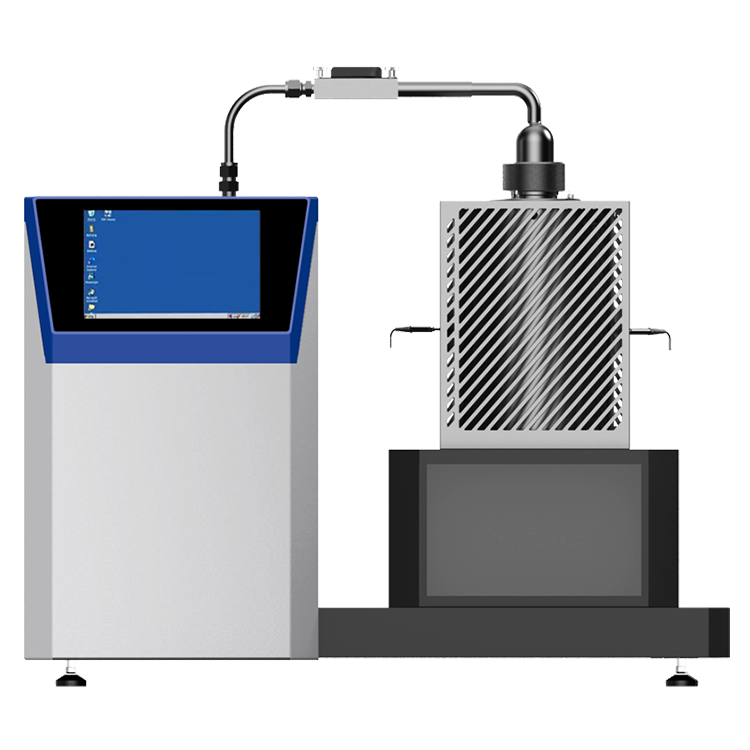

The Automatic Isoperibol Calorimeter is a semi-automated instrument that uses the principle of isoperibol calorimetry to measure the heat of combustion of a substance. The instrument consists of a combustion bomb, a water jacket, and a calorimeter vessel. The sample is placed in the combustion bomb, which is then filled with oxygen and ignited. The heat of combustion is transferred to the water jacket, which in turn heats the calorimeter vessel. The temperature rise of the calorimeter vessel is measured, and from this, the calorific value of the sample can be calculated.

The Automatic Isoperibol Calorimeter offers several advantages over traditional calorimeters. It has a high degree of automation, which reduces the risk of human error and increases the accuracy of the results. It is also designed to handle a large number of samples in a short amount of time, making it ideal for high-throughput laboratories. Additionally, it requires less maintenance than traditional calorimeters, which can save time and money in the long run.

Principles of Operation

Energy Measurement

The Automatic Isoperibol Calorimeter is a device used to measure the heat energy released by a sample during combustion. The instrument uses a fixed bomb and bucket design where the bomb and bucket are not removed from the calorimeter during routine operations. The sample is placed in a bomb, which is then filled with oxygen and ignited. The heat generated by the combustion reaction is absorbed by the surrounding water, causing it to heat up. The amount of heat transferred to the water is measured by the calorimeter, which calculates the heat of combustion of the sample.

Temperature Control

The temperature of the calorimeter is carefully controlled to ensure accurate measurements. The temperature of the water in the calorimeter is maintained at a constant temperature, which is typically around 25°C. The temperature of the bomb is also monitored to ensure that it does not exceed a certain temperature, which could cause the sample to decompose or react in an undesired way. The temperature of the calorimeter is typically controlled using a feedback loop, which adjusts the temperature of the water in response to changes in the temperature of the bomb.

The Automatic Isoperibol Calorimeter is a powerful tool for measuring the heat of combustion of a wide range of samples. By carefully controlling the temperature of the calorimeter and the bomb, the instrument is able to provide accurate and reliable measurements of the heat of combustion of a sample.

Components and Design

The Automatic Isoperibol Calorimeter is a highly precise instrument used for measuring the heat of combustion of a sample. It consists of several components that work together to ensure accurate and reliable results. In this section, we will discuss the main components of the calorimeter and their design.

Sample Chamber

The sample chamber is the heart of the Automatic Isoperibol Calorimeter. It is where the sample is burned, and the heat of combustion is measured. The chamber consists of a bomb, bucket, and jacket. The bomb is a high-pressure vessel that holds the sample and oxygen. The bucket is a container that holds the water used to cool the chamber. The jacket is a surrounding water bath that maintains the chamber at a constant temperature.

The bomb and bucket are designed to be easily removable, allowing for quick and easy loading and unloading of samples. The bomb features a unique closure design that allows the user to seal and lock the head into the cylinder with a simple one-sixteenth turn. This design minimizes frictional wear and improves the lifetime of the main bomb seal, which is an o-ring optimized for this purpose.

Thermometric System

The thermometric system is responsible for measuring the temperature change in the sample chamber during combustion. It consists of a thermistor, a bridge circuit, and a digital voltmeter. The thermistor is a temperature-sensitive resistor that is placed inside the sample chamber. The bridge circuit is used to measure the change in resistance of the thermistor as the temperature changes. The digital voltmeter is used to display the temperature change in the chamber.

The thermometric system is designed to be highly accurate and precise. The thermistor is calibrated before each use to ensure that it is reading the correct temperature. The bridge circuit is designed to be highly sensitive, allowing for precise measurements of temperature changes.

Ignition System

The ignition system is responsible for igniting the sample in the bomb. It consists of a spark plug, a capacitor, and a transformer. The spark plug is inserted into the bomb and is used to ignite the sample. The capacitor is used to store electrical energy, which is then discharged through the spark plug to create a spark. The transformer is used to increase the voltage of the electrical energy, allowing for a larger spark.

The ignition system is designed to be highly reliable and consistent. The spark plug is designed to be easily replaceable, allowing for quick and easy maintenance. The capacitor and transformer are designed to be highly efficient, allowing for consistent ignition of the sample.

Overall, the Automatic Isoperibol Calorimeter is a highly precise and reliable instrument that is used for measuring the heat of combustion of a sample. Its components are designed to be highly accurate and precise, allowing for consistent and reliable results.

Calibration and Standards

Calibration Procedure

To ensure accurate and reliable measurements, the Automatic Isoperibol Calorimeter should be calibrated regularly. The calibration procedure involves measuring the heat of combustion of a reference substance, such as benzoic acid, and comparing it to the known value.

The calibration process is automated and controlled by the calorimeter software. The software calculates the calibration factors based on the heat of combustion of the reference substance and adjusts the calorimeter accordingly. It is recommended to perform the calibration procedure at least once a year, or more frequently if the instrument has been repaired or modified.

Reference Standards

Reference standards are used to verify the accuracy and reliability of the calorimeter measurements. The standards should be traceable to a national or international standard, such as NIST (National Institute of Standards and Technology) or ISO (International Organization for Standardization).

The Automatic Isoperibol Calorimeter is designed to comply with ASTM (American Society for Testing and Materials) standards for bomb calorimetry. The instrument is capable of measuring the heat of combustion of various substances, including solids, liquids, and gases, with high precision and accuracy.

To ensure the validity of the measurements, it is important to use high-quality reference standards and follow the recommended procedures for their use. The reference standards should be stored and handled carefully to avoid contamination or degradation.

In summary, calibration and reference standards are crucial for maintaining the accuracy and reliability of the Automatic Isoperibol Calorimeter measurements. By following the recommended procedures and using high-quality standards, you can ensure that your measurements are consistent and trustworthy.

Data Analysis

Correction Factors

When analyzing the data obtained from an Automatic Isoperibol Calorimeter, it is important to take into account correction factors that may affect the accuracy of the results. One such factor is the heat loss correction. This correction factor accounts for any heat loss that occurs during the experiment due to radiation or convection. It is calculated by measuring the temperature difference between the calorimeter and the surrounding environment before and after the experiment.

Another correction factor is the combustion correction. This correction factor is used to account for any incomplete combustion that may have occurred during the experiment. It is calculated by measuring the amount of unburned material left in the bomb after the experiment.

Calculating Results

Once the correction factors have been taken into account, the results of the experiment can be calculated. The gross calorific value (GCV) is calculated by dividing the heat released during the experiment by the mass of the sample. The net calorific value (NCV) is calculated by subtracting the heat of vaporization of any water produced during the experiment from the GCV.

It is important to note that the results obtained from an Automatic Isoperibol Calorimeter are highly accurate and precise. However, it is still important to take into account any correction factors that may affect the accuracy of the results. By doing so, you can ensure that the results obtained from the experiment are as accurate and precise as possible.

Applications and Uses

Material Testing

The Automatic Isoperibol Calorimeter is widely used in material testing to determine the calorific value of solid and liquid fuels, food items, and other materials. This device is particularly useful for testing the energy content of fuels such as coal, wood, and oil. The calorific value of these fuels is an important factor in determining their efficiency and cost-effectiveness. The Automatic Isoperibol Calorimeter is capable of measuring the gross calorific value (GCV) and net calorific value (NCV) of a wide range of materials, making it an essential tool in material testing.

Quality Control

The Automatic Isoperibol Calorimeter is also used in quality control applications. It is used to test the energy content of various products, such as food items and pharmaceuticals, to ensure that they meet certain standards. This device is capable of detecting even small variations in the calorific value of a product, making it an important tool in quality control. By using the Automatic Isoperibol Calorimeter, manufacturers can ensure that their products meet the required standards and are safe for consumption.

Overall, the Automatic Isoperibol Calorimeter is an essential tool in material testing and quality control applications. Its ability to accurately measure the calorific value of materials makes it an important device in a wide range of industries. Whether you are testing the energy content of fuels or ensuring the quality of food items, the Automatic Isoperibol Calorimeter is a reliable and efficient tool that can help you achieve your goals.