Precision Calorimeter Manufacturers: Innovations from Zeal Instruments

Calorimeter Manufacturers Founded on principles of continuous innovation and a commitment to excellence, Hangzhou Zeal Instruments has established itself as a leader in the development of advanced testing technologies and instruments. By focusing on the frontier exploration of new materials and new energy fields, Zeal Instruments provides essential tools that drive progress across various sectors. Among these tools, precision calorimeters stand out for their critical role in measuring the heat of chemical reactions or physical changes as well as heat capacity, thus serving vital functions in industries ranging from pharmaceuticals to renewable energy development.

Background of Hangzhou Zeal Instruments

Founding History and Milestones Calorimeter Manufacturers

Calorimeter Manufacturers Hangzhou Zeal Instruments Science & Technology Co., Ltd. was established in 2014 with a specific focus on the advancement of thermal analysis and nondestructive measurement technologies. Over the years, the company has become a trusted provider of professional solutions for thermal parameters testing and nondestructive evaluation, particularly in new materials and lithium-ion batteries. Their continued innovation and commitment to quality have positioned them at the forefront of their industry, aiding significant developments in various high-tech sectors.

Core Values and Mission Statement

At Calorimeter Manufacturers the heart of Hangzhou Zeal Instruments is a core mission to enhance the development of new materials through cutting-edge thermophysical property tests. As a leading developer of such instruments, Zeal Instruments strives to empower industries to innovate and improve their products, reflecting their commitment to pushing the boundaries of what’s possible in material science and engineering.

Key Personnel and Experts

Zeal Instruments prides itself on its robust team of over 20 research and development personnel who are at the core of the company’s innovation efforts. Additionally, the company holds more than 30 invention patents, underscoring its role as a leader in technological advancements in the field.

Precision Calorimeter Manufacturers Technology

Overview of Precision Calorimeters

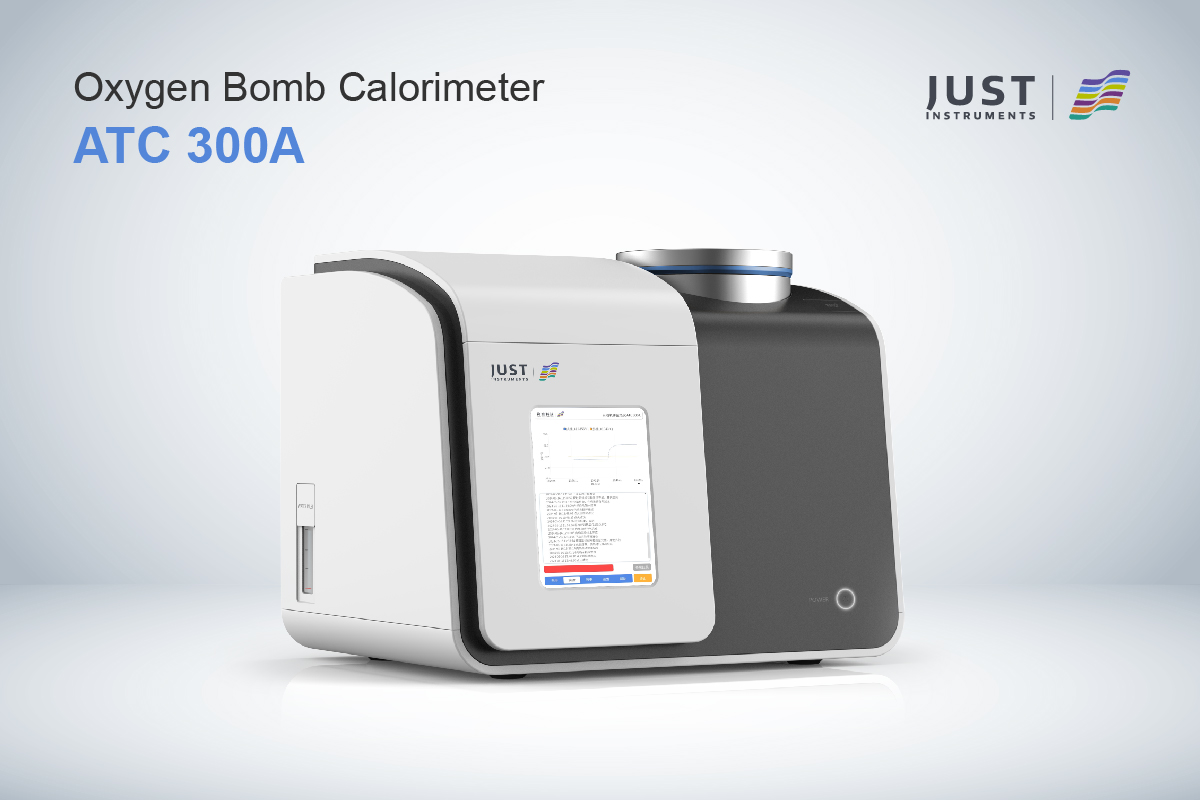

The ATC 300A, a standout model among Zeal Instruments’ offerings, adheres to international standards such as GB/T384, GB/T 213, ASTM 4809, and ASTM D240. This instrument is designed for rapid and accurate calorific value determination of various combustibles. It features an advanced temperature control system that guarantees both precision and repeatability, coupled with a user-friendly interface that enhances its usability. The automatic oxygen bomb calorimeter is indispensable in industries like coal, petrochemical, and biomass fuel, providing essential data for quality control and regulatory compliance.

Importance of Precision in Calorimetry

Calorimeter Manufacturers in calorimetry is paramount as it influences the reliability of data crucial for material development, energy production, and environmental monitoring. Accurate calorific measurements ensure that industries can maintain efficient processes, meet regulatory standards, and develop safer, more effective products.

Specifications and Operating Environment

The ATC 300A operates effectively within a temperature range of 15°C to 30°C and a maximum relative humidity of 80% without condensation. It utilizes either a cotton thread or an ignition wire as its ignition method. This precision calorimeter boasts a temperature resolution of 0.0001°C and operates in an isoperibol test mode. It can complete a test in less than 15 minutes and measures calorific values up to 34,000J with a precision of less than 0.10% and a fluctuation of less than 0.20%. The device’s oxygen bomb can withstand pressures up to 240 bar and is made from corrosion-resistant materials such as stainless steel and Hastelloy. Furthermore, it has a substantial data storage capacity, able to store up to 10000 entries.

Innovations by Zeal Instruments

Automated Features for Enhanced Efficiency

Hangzhou Zeal Instruments has revolutionized calorimetry with features like automatic bomb lifting, bomb serial number recognition, and automatic oxygen filling and release. Their systems ensure the seamless operation of oxygen pressure detection and internal and external water management for the calorimeter’s inner cylinder, eliminating the need for manual intervention and significantly enhancing the accuracy and reliability of test results.

Advanced Temperature and Environmental Control

A distinctive semiconductor cooling water circulation system equipped with a high-efficiency filter allows precise temperature trend monitoring and control during the heating, insulation, and cooling phases. This system swiftly achieves thermal equilibrium, thereby minimizing environmental interference, which is crucial for obtaining accurate calorimetric data.

User-Friendly Interface and Data Management

The integration of a touchscreen color LCD facilitates stable software operation and displays real-time data curves, making the testing process more intuitive. Additionally, the calorimeter features automatic ignition wire detection and short-circuit protection, enhancing both user safety and equipment longevity. Advanced data correction capabilities provide accurate calorific values by correcting for variables such as the heat produced by ignition wire combustion and the calorific values of various chemical substances.

Connectivity and Data Integration

Through the use of advanced serial port technology, multiple units can be controlled simultaneously without risk of experimental interference, making it ideal for larger laboratories managing numerous tests concurrently. The system also supports automatic generation and saving of charts and process data, along with historical data retrieval, which significantly enhances research efficiency and data analysis.

Enhancing Precision and Efficiency

The automatic oxygen bomb calorimeter offers exceptional temperature control accuracy through its semiconductor refrigeration water circulation system, achieving faster and more precise temperature stabilization compared to external cooling methods. The instrument simplifies experimentation with automated functions like lifting, oxygenation, and exhaust, minimizing operator error. It features a secure, independent database and a unique software model that displays calorific value curves and supports multiple unit conversions in real time. Additionally, its design includes specialized ignition wire detection and circuit protection technologies, enhancing safety and prolonging the device’s operational lifespan.

Applications of Oxygen Bomb Calorimeter

Fuel Analysis

The Oxygen Bomb Calorimeter is extensively employed in various industries for fuel analysis. In sectors like coal and biofuels, it accurately measures the heat released during combustion, providing crucial data for assessing fuel quality and efficiency. This analysis aids in optimizing combustion processes, enhancing energy production, and meeting environmental standards.

Quality Control in Food Industry

In the food industry, precise measurement of calorific value is essential for quality control and nutritional labeling. The calorimeter assists in determining the energy content of food products through combustion analysis. This ensures compliance with regulatory standards, facilitates product development, and helps consumers make informed dietary choices.

Research and Development

Beyond industrial applications, the Oxygen Bomb Calorimeter serves as a valuable tool in research and development across diverse fields. Material testing institutions utilize it to assess the calorific value of various materials, aiding in the development of new construction materials and optimizing manufacturing processes. Additionally, in biology and engine technology research, such as in the study of kerosene and jet fuel, this device provides crucial insights into energy release mechanisms, contributing to advancements in fuel efficiency and environmental sustainability.

Future Directions and Potential Developments

Research and Development Initiatives

Hangzhou Zeal Instruments is investing heavily in R&D to further enhance the precision and efficiency of their calorimeters. Current projects include the development of micro-calorimeters that could revolutionize the measurement of minute thermal changes in highly sensitive materials and biological samples.

Expansion into New Markets and Industries

With a solid foundation in pharmaceuticals, chemicals, and food industries, Zeal Instruments plans to expand its reach into new markets such as biotechnology and environmental science. This expansion is driven by the growing demand for precise thermal analysis in research and industry-specific applications, positioning Zeal as a global leader in calorimetry solutions.

Final Thoughts

Hangzhou Zeal Instruments continues to set the standard in the field of precision calorimetry with its innovative approach and cutting-edge technology. Their automatic oxygen bomb calorimeter exemplifies this by offering unparalleled temperature control, ease of operation, and data accuracy, which are essential for a wide range of industries. By integrating automated functionalities, advanced safety features, and robust data handling capabilities, Zeal Instruments not only enhances the efficiency and reliability of thermal analysis but also ensures the longevity and protection of the equipment. These advancements underscore Zeal Instruments’ commitment to pushing the boundaries of material testing and energy research, solidifying their role as a leader in precision calorimeter manufacturing.