Cell Thermal Conductivity Meter: A Comprehensive Guide

If you are working in the field of thermal conductivity, then you know how important it is to have accurate and reliable measurements. One tool that can help you achieve this is a cell thermal conductivity meter. This device allows you to measure the thermal conductivity of a wide range of materials, from liquids and gases to solids and powders.

A cell thermal conductivity meter works by measuring the rate at which heat flows through a material. This is done by placing the material in a cell and applying a temperature gradient across it. The meter then measures the temperature difference across the material and calculates its thermal conductivity. This information can be used to determine the material’s ability to conduct heat, which is important in many applications, including materials science, engineering, and manufacturing.

Whether you are a researcher, engineer, or manufacturer, a cell thermal conductivity meter can be an invaluable tool for understanding the thermal properties of your materials. With accurate and reliable measurements, you can make informed decisions about how to optimize your processes and products. So if you are looking for a way to improve your thermal conductivity measurements, consider investing in a cell thermal conductivity meter.

Fundamentals of Thermal Conductivity

Thermal conductivity is the property of a material that determines how well it conducts heat. The thermal conductivity of a material is defined as the amount of heat that is transferred through a unit thickness of the material per unit of time and per unit area when there is a temperature difference across the material. The units of thermal conductivity are watts per meter kelvin (W/mK).

Thermal Conductivity in Cells

Thermal conductivity in cells is an important property that determines the rate of heat transfer within the cell. The thermal conductivity of a cell is influenced by various factors such as the cell membrane, cell wall, cytoplasm, and organelles. The thermal conductivity of a cell can be measured experimentally using various techniques such as the transient hot wire method, the laser flash method, and the 3-omega method.

Measurement Principles

The transient hot wire method is a popular technique for measuring the thermal conductivity of cells. In this method, a thin wire is inserted into the cell, and a current is passed through the wire to heat it up. The temperature rise of the wire is measured, and the thermal conductivity of the cell is calculated using the temperature rise, the wire length, and the wire diameter.

The laser flash method is another technique used for measuring the thermal conductivity of cells. In this method, a laser pulse is used to heat the cell, and the temperature rise is measured using a detector. The thermal conductivity of the cell is calculated using the temperature rise, the laser pulse duration, and the cell thickness.

The 3-omega method is a non-destructive technique used for measuring the thermal conductivity of cells. In this method, a thin metal film is deposited on the cell, and a high-frequency current is passed through the film. The temperature rise of the film is measured, and the thermal conductivity of the cell is calculated using the temperature rise, the film thickness, and the frequency of the current.

In conclusion, thermal conductivity is an important property of cells that determines the rate of heat transfer within the cell. The thermal conductivity of a cell can be measured experimentally using various techniques such as the transient hot wire method, the laser flash method, and the 3-omega method.

Cell Thermal Conductivity Meter Design

Sensor Technologies

Cell thermal conductivity meters utilize various sensor technologies to measure the thermal conductivity of a cell. One common technology is the four-electrode design, which compensates for fouling, cable and connector polarization errors, and fringe field interference errors. Each conductivity cell is made from graphite and housed in an epoxy outer shell to withstand prolonged rough outdoor conditions.

Device Architecture

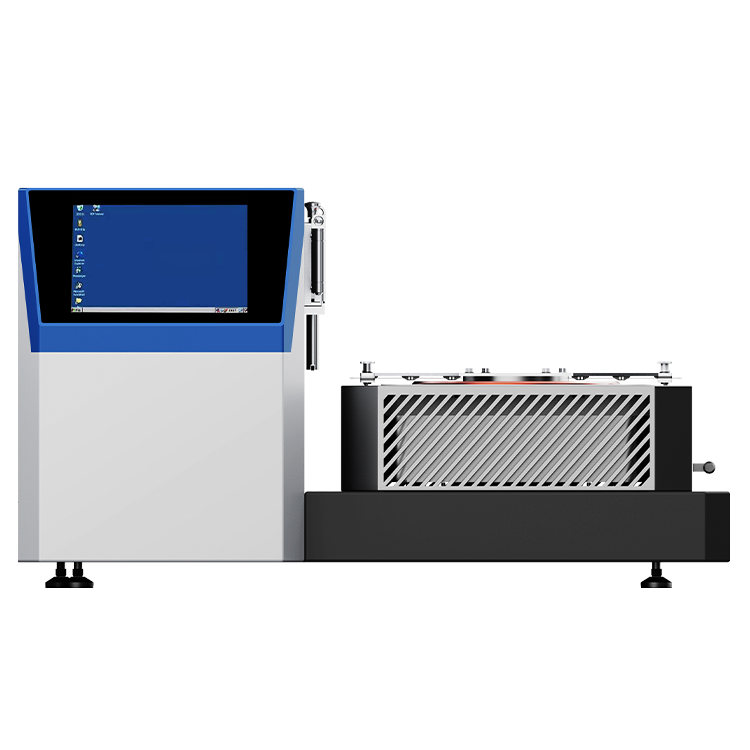

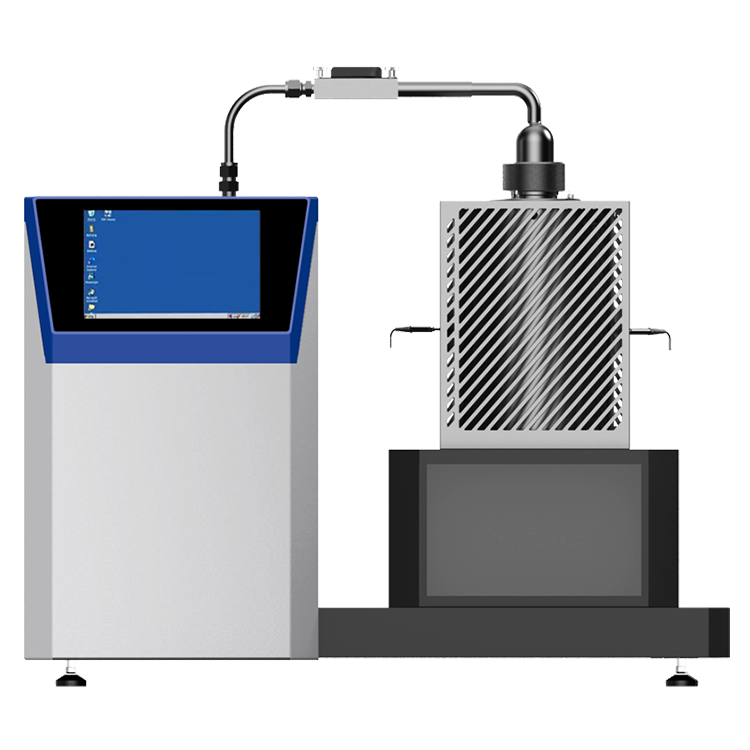

Cell thermal conductivity meters are designed to deliver performance, accuracy, and reliability. The device architecture is usually composed of a conductivity meter and a conductivity cell. The conductivity meter is the main unit that measures the thermal conductivity of the cell. It usually has a digital display that shows the conductivity value in Siemens (S). The conductivity cell is the part of the device that contains the sample being measured. It is connected to the conductivity meter via a cable and connector.

The device architecture also includes a temperature sensor that measures the temperature of the cell. The temperature value is then used to calculate the thermal conductivity of the cell. The device may also include a data logger that records the conductivity and temperature values over time. This allows for the analysis of trends and patterns in the data.

In summary, cell thermal conductivity meters utilize various sensor technologies to measure the thermal conductivity of a cell. They are designed to deliver performance, accuracy, and reliability. The device architecture includes a conductivity meter, a conductivity cell, a temperature sensor, and a data logger.

Operation of Cell Thermal Conductivity Meters

Cell thermal conductivity meters are used to measure the thermal conductivity of cells. These meters are designed to measure the heat transfer rate of cells by monitoring the cooling time of a heated element in the cell. The thermal conductivity of cells can be an important parameter in many biological and medical applications, including cancer research and drug development.

Calibration Procedures

Before using a cell thermal conductivity meter, it is important to calibrate the instrument to ensure accurate measurements. Calibration procedures typically involve measuring the thermal conductivity of a standard material, such as water or a reference cell, and comparing the results to known values. The calibration process should be performed periodically to ensure that the instrument remains accurate over time.

Data Acquisition and Processing

To measure the thermal conductivity of cells, a sample is placed in the cell of the thermal conductivity meter and heated. The heat transfer rate is then measured by monitoring the cooling time of the heated element in the cell. The data is typically recorded and processed using software that calculates the thermal conductivity of the cell.

Data acquisition and processing can be a critical step in obtaining accurate measurements of cell thermal conductivity. It is important to ensure that the data is collected and processed correctly to avoid errors and inaccuracies in the results. Some thermal conductivity meters may also have additional features, such as the ability to measure other parameters, such as temperature or electrical conductivity.

Overall, cell thermal conductivity meters are valuable tools for measuring the thermal conductivity of cells. With proper calibration and data acquisition and processing, these instruments can provide accurate and reliable measurements that can be used in a variety of biological and medical applications.

Applications of Cell Thermal Conductivity Meters

Cell Thermal Conductivity Meters are useful tools that can be used in various applications. Some of the most common applications of these meters are discussed below:

Research and Development

In research and development, Cell Thermal Conductivity Meters are used to measure the thermal conductivity of different materials. This information is important in the development of new materials and products, as it can help researchers determine which materials are best suited for specific applications. By measuring the thermal conductivity of different materials, researchers can also gain a better understanding of how these materials behave under different conditions.

Quality Control in Manufacturing

Cell Thermal Conductivity Meters are also used in quality control in manufacturing. By measuring the thermal conductivity of different materials, manufacturers can ensure that their products meet certain standards. For example, in the electronics industry, manufacturers use Cell Thermal Conductivity Meters to ensure that the thermal conductivity of their products is within certain limits. This is important because if the thermal conductivity of a product is too high or too low, it can affect its performance and reliability.

In addition to the above applications, Cell Thermal Conductivity Meters can also be used in other fields such as materials science, energy research, and environmental monitoring. Overall, these meters are valuable tools that can help researchers and manufacturers better understand the thermal properties of different materials.

Challenges and Limitations

Material Constraints

When using a Cell Thermal Conductivity Meter, there are some material constraints that you need to keep in mind. The device is not suitable for measuring the thermal conductivity of all materials. For instance, materials that are highly reflective or transparent, such as metals or glass, may not produce accurate readings. In addition, materials that are too thin or too small may not provide enough surface area for the device to measure accurately.

Environmental Factors

Another challenge when using a Cell Thermal Conductivity Meter is environmental factors. The device is sensitive to changes in temperature, humidity, and air pressure. Therefore, it is important to ensure that the testing environment is stable and controlled. Any changes in the environment can affect the accuracy of the readings.

In addition, the device may not be suitable for use in extreme temperatures or harsh environments. For example, if the material being tested is too hot or too cold, it may affect the accuracy of the readings. Similarly, if the material is exposed to harsh chemicals or radiation, it may damage the device or affect the accuracy of the readings.

Overall, while the Cell Thermal Conductivity Meter is a powerful tool for measuring the thermal conductivity of materials, it is important to keep in mind the material constraints and environmental factors that can affect its accuracy. By ensuring that the testing environment is stable and controlled, and by carefully selecting the materials to be tested, you can achieve accurate and reliable results with this device.