Are Closed Cup Flash Point Analyzer the Safest Option for Your Testing Needs?

Discover the advantages, limitations, and safety considerations of Closed Cup Flash Point Analyzers, along with strategies for choosing the right model. Explore the expertise of Zeal Instruments, a leading manufacturer, and ensure precision, safety, and compliance in your testing processes. Learn how to overcome challenges and maximize the benefits of closed cup flash point analysis in diverse industries.

Introduction

Understanding the flash point of flammable substances is critical in industries where handling and storage of such materials are common. The flash point, marking the temperature at which a substance emits a vapor that can ignite, is essential for safe handling and transportation. Closed cup flash point analyzers are pivotal in determining these points, ensuring safety and quality control. Industries like petrochemicals, pharmaceuticals, and automotive rely on accurate flash point measurements for safe processing, formulation, and optimal performance. From volatile fuels to medications and lubricants, knowing flash points is indispensable for maintaining safety and quality in various sectors.

Closed Cup Flash Point Analyzers: Ensuring Safety and Quality Control

Closed cup flash point analyzers, and sophisticated instruments, precisely measure the flash point of flammable liquids in a controlled environment. Gradually heating the sample, they detect the ignition temperature, offering a safer alternative to open cup methods by enclosing the sample, minimizing vapor release risks. Zeal Instruments, a leading manufacturer, is renowned for accurate, reliable, and user-friendly closed-cup flash point analyzers. Widely utilized across industries, their instruments ensure precise measurements and robust performance, making them indispensable for safety and quality control.

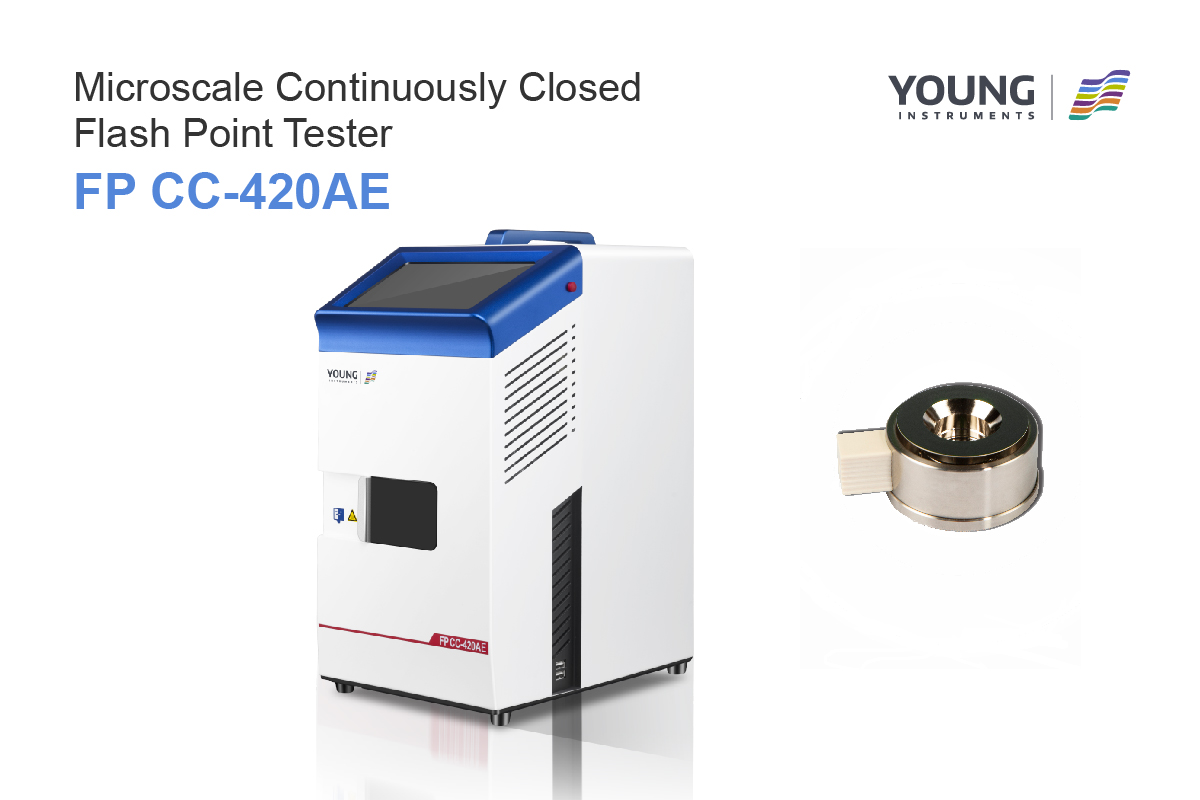

Zeal Instruments introduces Microscale Continuous Closed Flash Point Tester (FP CC-420AE), addressing the challenges faced during flash point measurements. These devices significantly enhance safety and ease of operation by tackling issues such as slow testing speeds, inaccurate measurements, large sample usage, gas pollution, poor repeatability, cumbersome operation, stringent testing conditions, and instrument instability.

1.1 Customized Testing

Microscale Continuous Closed Flash Point Tester (FP CC-420AE) not only facilitates standard testing methods but also offer customized parameter scanning for special samples, providing versatility in testing procedures.

1.2 Technical Specifications

- Operating Environment: 5°C to 35°C, <85% RH

- Temperature Control Range:0~260℃;-30℃~260℃ (low-temperature module); 0~420℃ (high-temperature module); -30℃~420℃ (both low-temperature and high-temperature modules)

- Temperature rise speed (2.5±0.3)℃/min, (5.5±0.5)℃/min, 1.0℃/min to 10℃/min customized

- Temperature Measurement Accuracy: ±0.1℃

- Pressure Testing Range: 0 to 200kPa

- Sample Size: 1ml or 2ml

- Ignition Mode: high-voltage electron ignition

- Stirring Speed: 50rpm to 300rpm, adjustable

- Data Storage Capacity: ≥5,000 entries

- Interface: RS232*1, RJ45*1, USB*2

- Rated Voltage: AC220V/50Hz

- Rated Power: 300W

- Dimension: 225mm × 310mm × 415mm

- Weight: 13.5kg

1.3 Product Features

- High Safety: Ensures safety with high-performance, compact, lightweight design.

- Short Testing Time: Facilitates quick and accurate testing.

- Portable: Portable automatic micro-volume closed-cup flash point tester.

- Compliance: Complies with safety flash point testing standards such as ASTM D6450, ASTM D7094, ASTM D93, and ASTM D3828.

- Low Sample Requirement: Requires minimal sample volume of 1-2ml.

- Wide Temperature Testing: Conducts continuous closed-cup testing without open flames or irritating gases, with a temperature range from -30°C to 400°C.

- Visual Analysis: Features a fully automatic closed-cup flash point instrument with visual combustion curve analysis.

- Portable Design Philosophy: Integrates a compact, portable design suitable for both laboratory and outdoor environments for rapid testing.

- Automatic Ignition and Cleaning Program: Automatically cleans residual substances attached to the ignition system, ensuring precise testing.

Applications of Closed Cup Flash Point Analyzers

2.1 Exploration of Crucial Industries

Microscale Continuous Closed Flash Point Tester (FP CC-420AE) finds applications in diverse industries, including petrochemicals, pharmaceuticals, and automotive.

- Petrochemical Sector: In petrochemical refineries, closed cup flash point analyzers are used to determine the flash points of various fuels, solvents, and chemicals, ensuring safe handling and processing.

- Pharmaceutical Industry: Pharmaceutical companies utilize closed cup flash point analysis to assess the flammability of solvent-based formulations, ensuring compliance with safety regulations and quality standards.

- Automotive Sector: Closed cup flash point testing is integral to the automotive industry for assessing the flash points of engine oils, fuels, and lubricants, ensuring optimal performance and safety.

2.2 Regulatory Requirements and Standards

Discussion on regulatory requirements and standards related to flash point testing emphasizes the importance of compliance with safety regulations and industry standards. Zeal Instruments’ analyzers are designed to meet or exceed these requirements, providing reliable and accurate measurements for regulatory compliance.

Advantages of Closed Cup Flash Point Analyzers

Closed cup flash point analyzers offer several advantages over other testing methods, making them preferred choices in industries dealing with flammable substances. These advantages include:

- Precise Measurement: Closed cup flash point analyzers provide precise measurements of the flash point temperature, ensuring accuracy in determining the flammability of substances.

- Enclosed Environment: The closed cup design minimizes vapor release during testing, enhancing safety and reducing the risk of accidents.

- Versatility: Closed cup flash point analyzers can test a wide range of substances, including volatile liquids, semi-solids, and solids, making them suitable for diverse applications.

Safety Considerations in Closed Cup Flash Point Testing

When conducting closed cup flash point tests, safety should be a top priority. Several safety protocols and procedures should be followed to mitigate risks:

- Ventilation: Ensure proper ventilation in the testing area to prevent the buildup of flammable vapors and reduce the risk of fire or explosion.

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety glasses, gloves, and lab coats, to protect against potential hazards.

- Fire Safety Equipment: Keep fire extinguishers and other fire safety equipment readily available in the testing area to respond quickly to emergencies.

Choosing the Right Closed Cup Flash Point Analyzer

Selecting the right closed cup flash point analyzer is crucial for accurate and reliable testing. Factors to consider include:

- Throughput: Determine the testing throughput requirements based on the volume of samples processed regularly.

- Accuracy:Evaluate the accuracy and precision of the analyzer’s measurements to ensure reliable results.

- Compliance Requirements:Ensure that the chosen analyzer complies with relevant industry standards and regulations.

When comparing different models and brands of closed cup flash point analyzers, consider:

- Features and Specifications:Compare the features and specifications of various analyzers to find the one that best meets your specific needs.

- User Reviews: Read user reviews and testimonials to gauge the performance and reliability of different models.

- Support and Service: Consider the availability of technical support and service from the manufacturer to address any issues or concerns.

By carefully evaluating these factors and following best practices for safety and testing, you can choose the right closed cup flash point analyzer for your application, ensuring accurate and reliable results while prioritizing safety.

Conclusion

In conclusion, closed cup flash point analyzers, such as Microscale Continuous Closed Flash Point Tester (FP CC-420AE) manufactured by Zeal Instruments, play a vital role in ensuring safety and quality control in industries dealing with flammable substances. By accurately determining the flash points of materials, these analyzers mitigate risks and facilitate compliance with regulatory standards, contributing to safer workplaces and products.