Closed Cup Flash Point Test Method for Determining Combustion Hazard Characteristics

The Closed Cup Flash Point Test Method is crucial for assessing the combustion hazard characteristics of various substances. This method, widely used in industries like petrochemicals and chemicals, determines the lowest temperature at which vapors above a liquid ignite. Accurate flash point determination ensures safety and compliance with international standards. According to the ASTM D93 standard, closed cup methods are more precise and safer, capturing vapors that mimic real-world conditions. For instance, transformer oil flash points typically range between 140°C to 180°C, while gasoline flash points are around -43°C. These values are essential for handling, storage, and transportation safety, reducing the risk of fire-related incidents. The FP CC-420AE Microscale Continuously Closed Flash Point Tester exemplifies advanced closed cup testing, offering versatility and accuracy for a wide range of substances, ensuring reliable data for safety assessments.

Product Introduction

The FP CC-420AE Microscale Continuous Closed Microscale Continuously Closed Flash Point Tester is a state-of-the-art instrument designed to determine the combustion hazard characteristics of various substances. Utilizing the continuous closed cup method, this tester offers precise determination of closed cup flash points for a broad spectrum of materials, including petroleum products, transformer oils, turbine oils, paints, fragrances, wood preservatives, essential oils, animal and plant oils, pesticide emulsifiers, high viscosity materials, and plasticizers. Its versatility makes it indispensable in fields such as petroleum, petrochemicals, and chemicals.

Advanced Testing Methods

The FP CC-420AE stands out by allowing users to adjust test parameters to perform not only the continuous closed cup method but also the Pensky-Martens closed cup method and the Rapid Equilibrium closed cup method. This flexibility ensures that the tester maintains excellent correlation with these established methods. Additionally, the tester can handle special samples through a custom parameter scanning method, enhancing its application range and reliability in providing accurate flash point data.

Key Features and Advantages

The FP CC-420AE adopts an advanced continuously closed cup flash point test method, which offers higher precision and efficiency. It requires a small sample size, reducing testing costs and minimizing pollution. The closed cup operation without an open flame enhances safety. The built-in refrigerating module allows for a wide range of flash point tests with short cooling times. The device features a full-automatic test process, automatic flash point calibration with atmospheric pressure, and real-time display of temperature and pressure curves. These capabilities provide a direct and detailed test process, with results including temperature-pressure rise curves for more comprehensive flash point information.

User-Friendly Design

The FP CC-420AE is designed with user convenience in mind. It features a USB port for plug-and-play functionality and a thermal printer for easy data management. The 7-inch color touchscreen supports Chinese input, making operations straightforward and intuitive. This user-friendly design ensures that operators can quickly and easily conduct tests and manage results, enhancing overall efficiency.

Compliance with Standards

The FP CC-420AE meets various international standards, including SH/T 0768, SN/T 3077.1, DL/T 1354, ASTM D6450, SN/T 3077.2, ASTM D7094, GB/T 261, GB/T 21615, ASTM D93, GB/T 5208, GB/T 21790, and ASTM D3828. Compliance with these standards guarantees that the tester provides accurate and reliable data, essential for ensuring safety and regulatory compliance in various industries.

Specifications

The FP CC-420AE operates in environments ranging from 5°C to 40°C with less than 85% relative humidity. It offers a temperature control range of 0-260°C, with optional low-temperature and high-temperature modules extending the range to -30°C to 420°C. The temperature rise speed is adjustable from 0.5°C/min to 12°C/min, with measurement accuracy within ±0.1°C. The pressure testing range is 0 to 200 kPa, and the sample size required is either 1 mL or 2 mL. The device uses high-voltage electron ignition and has an adjustable stirring speed from 50 rpm to 300 rpm. It can store up to 25,000 data entries and includes interfaces for RS232, RJ45, and USB. The rated voltage is AC220V/50Hz with a power consumption of 300W.

The FP CC-420AE Microscale Continuous Closed Microscale Continuously Closed Flash Point Tester is an advanced, versatile, and user-friendly instrument essential for accurately determining the flash points of various substances, ensuring safety, and compliance across multiple industries.

Product Application – Measuring the Flash Point of Ionic Liquids

Experimental Background

In recent years, ionic liquids synthesized in laboratories have found extensive use in chemical separation, organic synthesis, electrochemistry, materials processing, and other fields. As new ionic compounds, ionic liquids exhibit significant property variations between different types, and their physicochemical parameters lack a unified standard. The flash point value is crucial for ensuring the safety performance of ionic liquids during use, making it essential to obtain accurate parameter values. Due to their low vapor pressure, ionic liquids present a challenge for rapid heating test methods, as fewer escaping gases make it difficult to observe flashover under an electric spark, thereby preventing the acquisition of a flash point value. The Microscale Continuous Closed Microscale Continuously Closed Flash Point Tester is specifically designed to address this challenge.

Experimental Method

For testing ionic liquids, the procedure begins by scanning the sample over a wide temperature range to identify a suspected flash point, generally below 100°C, with a testing time not exceeding 2 hours. This initial scan helps determine the instrument’s heating rate and the appropriate testing temperature range. Following this, a small-range scan test near the suspected flash point is conducted to quickly obtain the flash point. This method prevents significant changes in the sample properties during testing, ensuring accurate and reliable results.

Experimental Results

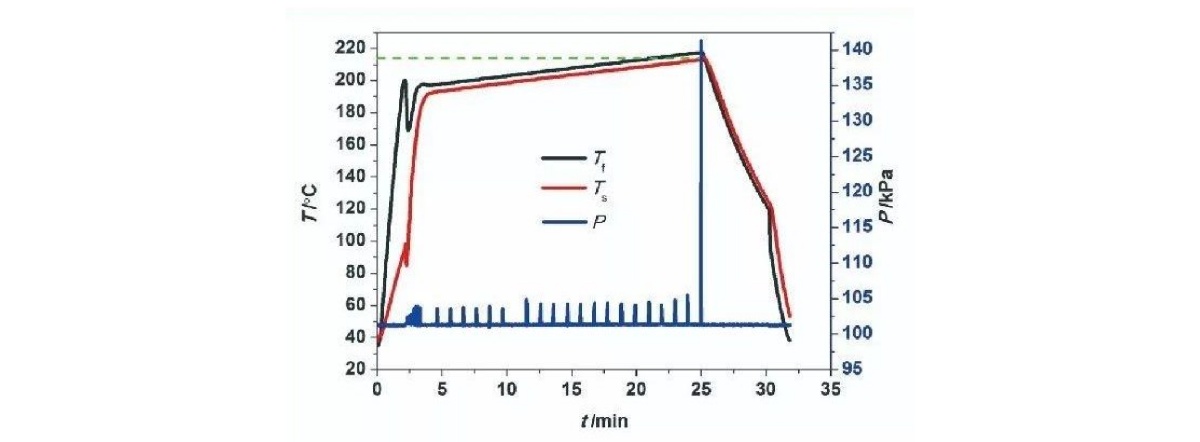

The data recorded during the testing of ionic liquid sample A using the FP CC-420AE Microscale Continuously Closed Flash Point Tester is shown in Figure 1. The sample temperature around 213°C caused a sudden increase in pressure within the sample cup, indicating this temperature as the flash point of sample A. Table 1 presents the four test results for ionic liquid sample A, with the flash point value consistently around 220°C, closely matching the predicted value. This consistency demonstrates the reliability and accuracy of the FP CC-420AE in measuring the flash point of ionic liquids, providing essential data for ensuring their safe use in various applications.

Figure 1 Data recorded during the testing of sample A (Tf—sample cup temperature, Ts—sample temperature, P—pressure inside the closed sample cup)

Table 1 Flash point test results for ionic liquid A

|

Experiment Number |

Heating Rate (°C/min) |

Temperature Range (°C) |

Calibrated Flash Point and Pressure Increasec |

|

A1 |

1.0 |

180-230 |

223.1℃,30.0kPa/223.0℃ |

|

A2 |

1.0 |

180-230 |

225.1℃,33.2kPa/225.0℃ |

|

A3 |

1.0 |

200-240 |

213.0℃,40.0kPa/213.0℃ |

|

A4 |

1.0 |

200-240 |

219.0℃,37.2kPa/219.0℃ |

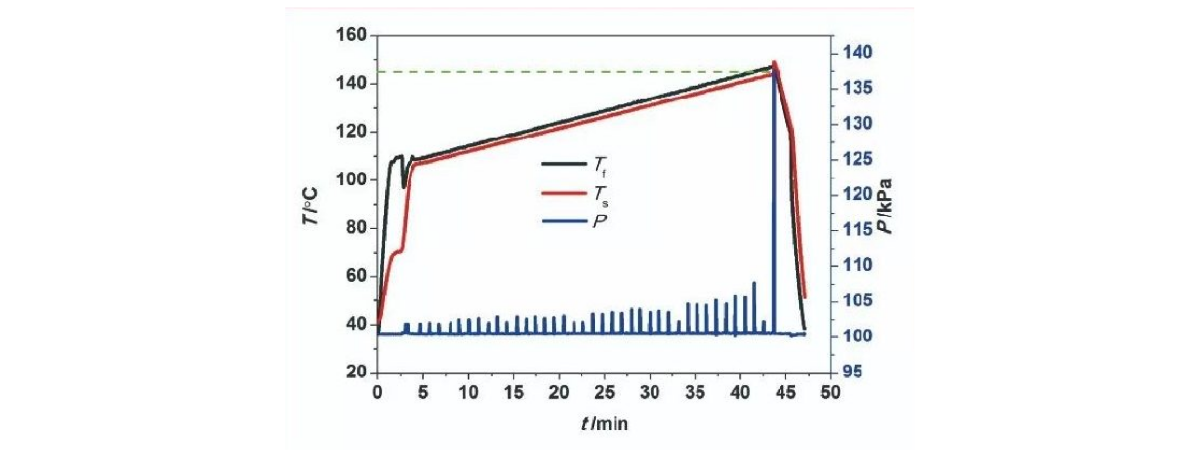

Figure 2 Data recorded during the testing of sample B with the FP CC-420A Microscale Continuously Closed Flash Point Tester (Tf—sample cup temperature, Ts—sample temperature, P—pressure inside the closed sample cup)

Table 2 Flash point test results for ionic liquid B

|

Experiment Number |

Heating Rate (°C/min) |

Temperature Range (°C) |

Calibrated Flash Point and Pressure Increase |

|

B1 |

1.0 |

110-150 |

144.2℃,37.1kPa/144.0℃ |

|

B2 |

1.0 |

120-150 |

143.2℃,41.2kPa/143.0℃ |

Final Words

The Closed Cup Flash Point Test Method is crucial for precisely assessing the combustion hazard characteristics of various materials. Advanced instruments such as the FP CC-420AE enable accurate flash point measurements for a range of substances, including petroleum products, transformer oils, turbine oils, paints, and fragrances. This method’s adaptability to different testing standards, including the Pensky-Martens and Rapid Equilibrium methods, guarantees both reliability and broad applicability. Accurate determination of flash point is essential for safety and regulatory compliance. Helps reduce fire risks in industries such as petrochemical and chemicals. The FP CC-420AE highlights the efficiency and effectiveness of the continuous closed cup method. Proving to be an indispensable tool for the safe handling, storage and transportation of combustible materials.