Expert Insights: Recommended Differential Scanning Calorimeter Manufacturers

Explore expert insights and recommendations on leading Differential Scanning Calorimeter manufacturers, including Zeal Instruments. Discover precision instruments for thermal analysis needs and learn about the advanced features and technical specifications of the DSC-40AE model. From defining the principles of DSC to its vital role in industries like materials science, food, chemistry, and pharmaceutical research, delve into the importance of thermal analysis and the unparalleled precision offered by innovative DSC technology. Stay ahead with the latest advancements, future trends, and opportunities in DSC instrumentation, ensuring excellence in material characterization and process optimization.

Introduction to Differential Scanning Calorimeter (DSC)

1. Definition and Working Principle of DSC

Differential Scanning Calorimeter (DSC) is a powerful analytical technique used to measure the heat flow associated with physical and chemical changes in materials as a function of temperature. It operates on the principle of comparing the heat flow to a reference material under controlled heating conditions. This allows for precise determination of various thermal properties of substances.

2. Importance of Thermal Analysis in Industries

Thermal analysis, particularly using techniques like DSC, plays a crucial role in industries such as coal, metallurgy, construction, and petrochemicals. It helps in understanding material behavior, optimizing processes, ensuring product quality, and developing innovative solutions.

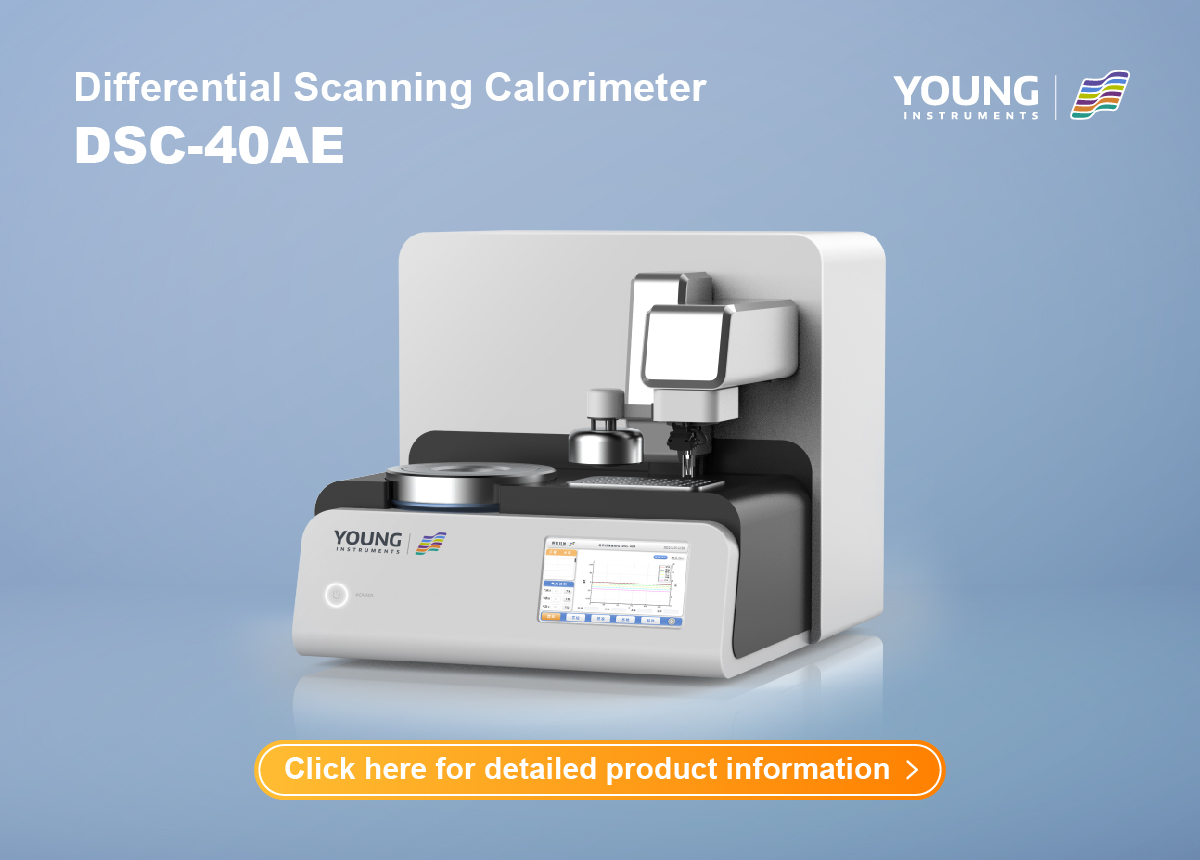

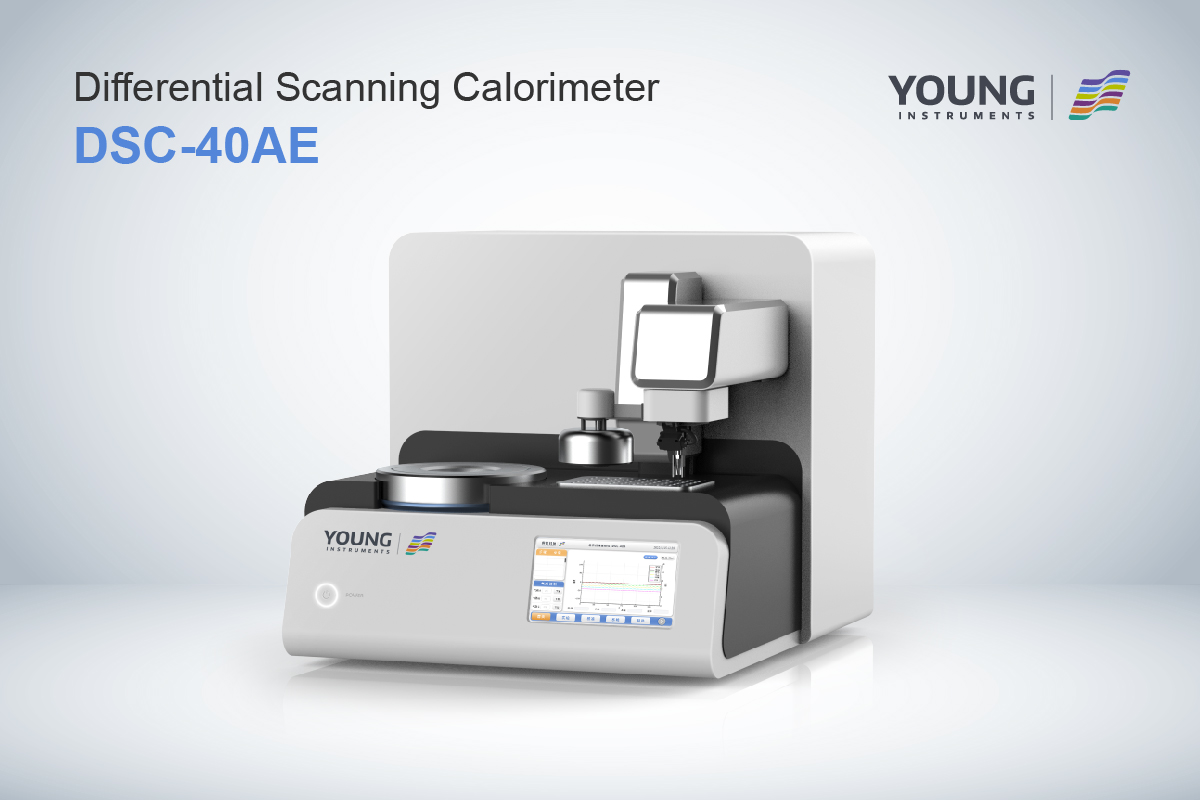

Introducing the DSC-40AE: Unraveling Material Properties with Precision

Product Overview:

The DSC-40AE offers unparalleled precision in thermal analysis, enabling the characterization of fundamental properties such as glass transition temperature, melting point, crystallization temperature, crystallinity, enthalpy of fusion, crystallization enthalpy, crystallization kinetics, reaction kinetics parameters, specific heat capacity, material compatibility, and gelation conversion rate, all with sample quantities in the milligram range.

The DSC-40AE is your ultimate companion for precise thermal analysis, providing insights crucial for various research and industrial applications.

Key Features:

- Tower-Type Heat Flow Technology:Leveraging mature tower-type heat flow technology to enhance instrument resolution and sensitivity.

- Silver Furnace Body:Ensuring higher heat transfer efficiency and reducing interference between reference and sample.

- Specialized Algorithm:Modulating temperature and heat flow signals through dedicated algorithms for precise data on specific heat capacity, reaction heat release, and more.

- Temperature Control Modes: Equipped with both heating and isothermal control modes for versatile testing scenarios.

- Comprehensive Analytical Functions:Offering a range of analytical functions including DSC Onset Point, Start set Point, Endset Point, baseline correction, peak heat flow, glass transition temperature, peak area, heat of absorption/release, peak temperature, extrapolation temperature, and specific heat.

- High Data Acquisition Frequency: Achieving a sampling rate of 50Hz to enhance sensitivity and resolution.

- Innovative Base Design: Enhancing sensor oxidation resistance at high temperatures and improving sensitivity and dynamic response.

- Optimized Structural Design: Providing reliable baseline stability and enhancing signal-to-noise ratio.

- High-Definition Touch Screen: Facilitating intuitive instrument operation.

Technical Specifications:

- Operating Environment: 5°C to 40°C, <85% RH

- Temperature Control Range: RT to 600°C

- Heating Scan Rate: 0.1K/min to 200K/min

- Scan Rate Deviation: ±1%

- Phase Transition Temperature Accuracy: ±0.1K

- Phase Transition Temperature Reproducibility: ±0.02K

- Enthalpy Accuracy: ±1%

- Enthalpy Measurement Precision: ±0.25%

- Baseline Stability: 200μW

- Baseline Reproducibility: ±15μW

- Heat Flow Display Resolution:0.1μW

- Heat Flow Peak Noise: 9μW

- Indium Peak Height/Half-peak Width: 8 mW/K

- TAWN Sensitivity: 3

- TAWN Resolution: 0.12

- Heat Flow Measurement Range: ±750 mW

- System Sampling Rate: 50Hz

- Gas Atmosphere Control: 3 channels, flow rate adjustable (0~300mL/min)

- Power Supply: AC220V/50Hz

- Power Consumption: 450W

- Dimensions: 505mm × 400mm × 355mm (L×W×H)

- Weight: 35kg

Application of DSC in Polymer Material Analysis

Differential Scanning Calorimetry (DSC) provides valuable insights into the physical and chemical changes occurring in polymer materials. It offers information on heat absorption, heat release, and changes in heat capacity during processes such as crystallization-melting and glass transition. These transitions represent fundamental changes between crystalline and amorphous polymers, reflecting alterations in the molecular motion states.

Additionally, DSC can investigate physical aging processes related to the movement of small-scale polymer units, making it an effective tool for studying polymer molecular dynamics.

- Evaluation of Thermal Oxidative Stability: Oxidation Induction Time (OIT) refers to the time taken for a sample to undergo an auto-catalytic oxidation reaction under specified temperature conditions in ambient pressure, air, or oxygen atmosphere, as determined by DSC. DSC allows for rapid determination of OIT, facilitating the selection of antioxidant types, dosages, and efficacy. It also enables the analysis of factors influencing material thermal oxidation aging based on material characteristics. Moreover, by establishing the linear relationship between OIT and test temperature and fitting equations by the Arrhenius equation, it’s possible to infer the anti-thermal oxidative aging lifespan at a given operating temperature.

- Chemical Composition Detection: By comparing the enthalpy change values of the sample with a reference material of known composition using DSC, it is possible to roughly estimate the chemical composition content in the sample.

- Analysis of Polymer Crystallization Behavior: The crystallization behavior of materials significantly affects their application performance. DSC characterization allows for the analysis of material crystallization behavior.

Application of DSC in Food Analysis

In food processing, heat is a ubiquitous parameter, involved in processes such as thermal sterilization, cooking, drying, and refrigeration. When food interacts with heat, various changes occur, including phase transitions (e.g., water and ice), alterations in protein conformation (ordered to disordered), changes in mass or composition, and variations in rheological properties. Most substances change heat capacity, structure, etc., with temperature variation, accompanied by changes in energy, making them amenable to study via DSC.

- Proteins: Different proteins possess distinct functional properties, closely related to their structures. The degree of protein denaturation affects protein structure, which further influences protein functionality. Protein denaturation during food processing plays a crucial role in certain properties of food systems. The process of protein denaturation is accompanied by energy changes, measurable using DSC.

- Starch: DSC is used to study the structure and properties of starch, especially thermodynamic properties. It can analyze the melting behavior of starch and starch mixtures, predict structure, and is a classic method for determining starch gelatinization and retrogradation. By establishing a standard curve to determine the relationship between a certain degree of starch gelatinization and the area under the DSC peak, starch gelatinization can be quantified. Additionally, the relationship between starch recrystallization molecular size and the area under the DSC peak can determine the degree of starch retrogradation. DSC is also used to measure energy changes during the gelatinization and aging phase transitions.

- Fats: Fats exhibit significant heat-induced phase transitions during heating and cooling processes, which are temperature-dependent. DSC can determine the crystallization kinetics, compositional changes, and thermodynamic properties of fats. Attempts have been made to apply DSC in monitoring the oxidation of fats to control fat processing. DSC can also guide the development of new varieties of fat substances, such as margarine and butter substitutes.

- Moisture Content: Water in food can be expressed in three ways: moisture content, water activity, and dynamic flowability of water. Water activity represents the degree of water binding in food, which can be divided into free water and bound water. Recent studies suggest that using the dynamic flowability of water to represent the interaction between water and food is more reasonable. DSC thermal analysis technology can be used to determine freezable water and unfreezable water in food systems.

- Fat Oxidation: Fats exhibit significant heat-induced phase transitions during heating and cooling processes, which are temperature-dependent. Differential scanning calorimetry (DSC) can measure the heat absorbed or released during sample phase transitions or the heat capacity of the sample, as well as determine the starting temperature, maximum reaction temperature, and end temperature of the reaction. DSC is based on these properties to study various sample properties.

Advancements in DSC Technology and Future Prospects

1. Recent Innovations in DSC Instrumentation and Software Capabilities

Manufacturers like Zeal Instruments are at the forefront of innovation in DSC technology, continually improving instrumentation and software capabilities to meet the evolving needs of industries. Recent advancements include higher temperature ranges, faster heating and cooling rates, improved sensitivity, and enhanced data analysis algorithms, allowing for more accurate and comprehensive material characterization.

2. Integration with Other Analytical Techniques

Integration of DSC with complementary analytical techniques, such as thermogravimetric analysis (TGA), Fourier-transform infrared spectroscopy (FTIR), and dynamic mechanical analysis (DMA), offers synergistic benefits for comprehensive material characterization. This integrated approach provides a more holistic understanding of material properties and behavior, enabling better-informed decision-making in research, development, and quality control processes.

3. Future Trends and Opportunities

Looking ahead, the future of DSC technology holds promising opportunities for leveraging its capabilities across diverse industrial sectors. Emerging trends include miniaturization of instrumentation for portable applications, automation and remote monitoring capabilities, and advancements in data analytics and artificial intelligence for predictive modeling and process optimization. These developments are expected to drive innovation, efficiency, and sustainability in materials science and engineering.

Conclusion

In conclusion, the Differential Scanning Calorimeter (DSC) is an indispensable tool for fields such as materials science, food, chemistry, pharmaceutical research, and more, enabling precise characterization of materials and optimization of processes. Manufacturers like Zeal Instruments play a vital role in providing cutting-edge DSC solutions that empower industries to achieve excellence in thermal analysis and drive innovation and efficiency in their operations.