DSC Analysis Machine: Understanding Its Function and Importance

If you’re looking to understand the thermal behavior of your materials, a Differential Scanning Calorimetry (DSC) analysis machine is an excellent tool to have in your lab. DSC analysis is a thermoanalytical technique that measures the difference in the amount of heat required to increase the temperature of a sample and a reference material as a function of temperature. This technique is used to study various thermal properties of materials, including glass transitions, melting points, and crystallization.

DSC analysis machines are used in a wide range of industries, including pharmaceuticals, polymers, and materials science. They are especially useful in the pharmaceutical industry, where they can be used to study the thermal behavior of drugs and excipients. In the polymers industry, DSC analysis machines are used to study the thermal properties of polymers, including glass transitions, melting points, and crystallization. Materials scientists also use DSC analysis machines to study the thermal properties of materials, such as metals, ceramics, and composites.

Fundamentals of DSC Analysis

Principles of DSC

Differential Scanning Calorimetry (DSC) is a thermal analysis technique that measures the amount of heat absorbed or released by a sample as it is heated or cooled. The DSC machine measures the difference in heat flow between a sample and a reference material as a function of temperature or time. The sample and reference materials are subjected to the same temperature program, and the heat flow difference is measured as a function of temperature.

DSC analysis is based on the principle that when a sample undergoes a physical or chemical change, such as melting or crystallization, it absorbs or releases heat. The amount of heat absorbed or released is proportional to the amount of material undergoing the change. DSC analysis is used to identify and characterize materials, determine thermal properties such as melting points and glass transition temperatures, and study chemical reactions such as curing and decomposition.

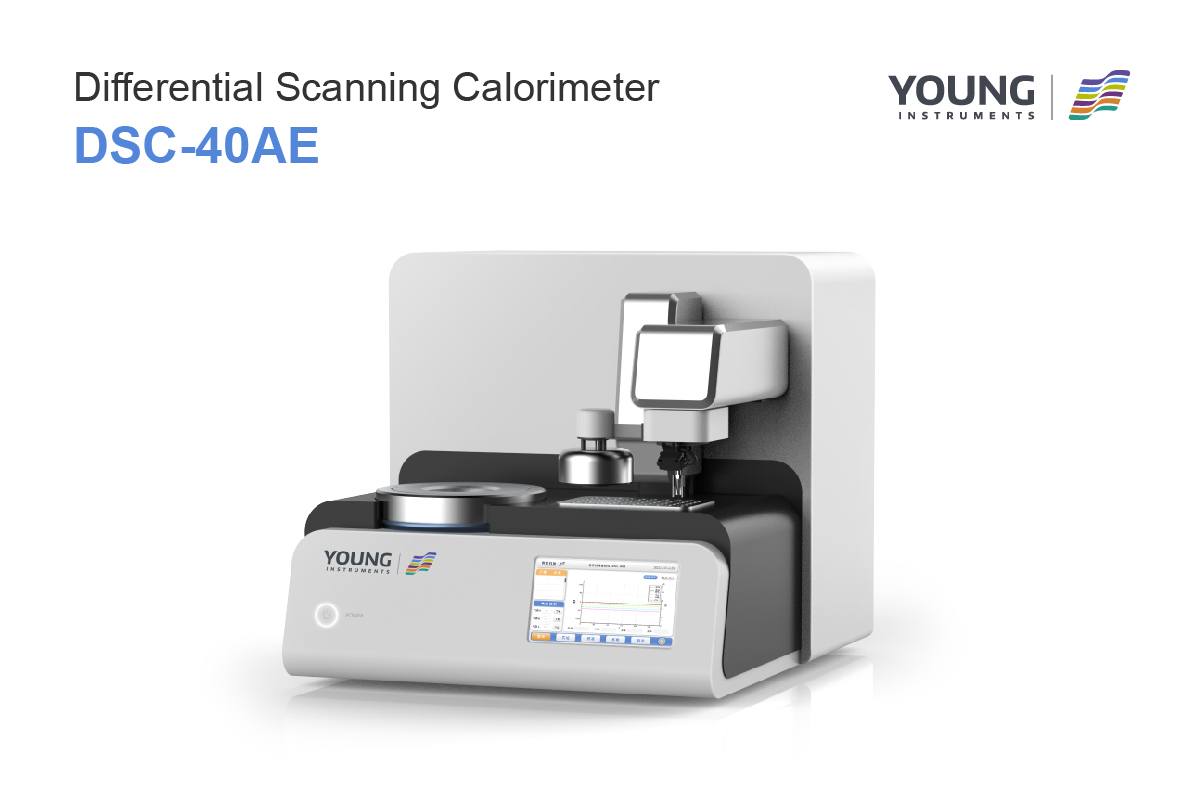

Components of a DSC Machine

A DSC machine consists of several components, including a furnace, a sample holder, a reference material holder, a temperature control system, and a heat flow sensor. The furnace provides a controlled heating and cooling environment for the sample and reference materials. The sample holder and reference material holder are designed to hold the sample and reference materials, respectively. The temperature control system regulates the temperature of the furnace, and the heat flow sensor measures the heat flow difference between the sample and reference materials.

The sample and reference materials are typically placed in small pans, which are then inserted into the sample holder and reference material holder, respectively. The pans are made of materials that have a high thermal conductivity, such as aluminum or platinum. The heat flow sensor is usually a thermocouple or a resistance thermometer, which measures the temperature difference between the sample and reference materials.

In summary, DSC analysis is a powerful technique for studying thermal properties and chemical reactions of materials. The DSC machine consists of several components, including a furnace, a sample holder, a reference material holder, a temperature control system, and a heat flow sensor. By measuring the heat flow difference between a sample and a reference material, DSC analysis can provide valuable information about the thermal behavior and chemical properties of materials.

DSC Machine Operation

Sample Preparation

Before running a DSC cycle, it is important to properly prepare your sample. The sample should be in a small, uniform shape and size. This can be achieved by cutting or grinding the sample to the desired size. It is also important to ensure that the sample is completely dry and free of any impurities. Any impurities can affect the results of the analysis.

Once the sample is prepared, it should be placed in the DSC machine. The sample can be placed in a sample pan, which is typically made of aluminum or platinum. The sample pan should be clean and free of any residue. The pan can be covered with a lid, which is also made of aluminum or platinum.

Running a DSC Cycle

To run a DSC cycle, you will need to set the parameters on the DSC machine. The parameters include the temperature range, the heating rate, and the cooling rate. These parameters will vary depending on the type of sample being analyzed.

Once the parameters are set, the DSC machine will begin to heat the sample at a constant rate. As the sample heats up, the DSC machine will measure the amount of heat absorbed or released by the sample. This information is used to determine the thermal properties of the sample, such as its melting point and specific heat capacity.

During the DSC cycle, it is important to monitor the results and take note of any changes in the sample. This can help to identify any impurities or anomalies in the sample. Once the DSC cycle is complete, the results can be analyzed and used to make informed decisions about the sample.

In summary, DSC machine operation involves preparing the sample and running a DSC cycle with carefully selected parameters. By following these steps, you can obtain accurate and reliable results that can be used to make informed decisions about your sample.

Data Interpretation

Thermogram Analysis

After running a Differential Scanning Calorimetry (DSC) experiment, you will receive a thermogram, which is a plot of heat flow as a function of temperature. To interpret the thermogram, you need to identify the different thermal events that occur during the experiment.

The most common thermal events are endothermic and exothermic peaks, which correspond to the absorption and release of heat, respectively. Endothermic peaks indicate that the sample is absorbing heat, while exothermic peaks indicate that the sample is releasing heat.

To identify the thermal events in the thermogram, you should look for peaks in the heat flow curve. Each peak corresponds to a thermal event, and the height and area of the peak provide information about the magnitude of the event.

Calorimetric Calculations

Once you have identified the thermal events in the thermogram, you can perform calorimetric calculations to determine the heat capacity, enthalpy, and other thermodynamic properties of the sample.

The heat capacity is the amount of heat required to raise the temperature of the sample by one degree Celsius. It can be calculated by dividing the heat absorbed or released by the sample by the corresponding temperature change.

The enthalpy is the heat absorbed or released by the sample during a thermal event. It can be calculated by integrating the area under the peak corresponding to the event.

Other thermodynamic properties that can be calculated from DSC data include the melting point, glass transition temperature, and crystallization temperature. These properties can provide valuable information about the chemical and physical properties of the sample, such as its purity, stability, and thermal behavior.

In summary, interpreting DSC data requires identifying the thermal events in the thermogram and performing calorimetric calculations to determine the thermodynamic properties of the sample. By understanding the thermal behavior of a sample, you can gain insights into its chemical and physical properties, which can be useful in a wide range of applications.

Applications of DSC Analysis

Differential Scanning Calorimetry (DSC) is a widely used thermal analysis technique that is used to measure enthalpy changes due to changes in the physical and chemical properties of a material as a function of temperature or time. The method allows you to identify and characterize materials. Here are some of the applications of DSC analysis:

Polymer Characterization

DSC analysis is used to study the thermal properties of polymers. The technique is used to measure the glass transition temperature, melting temperature, and crystallization temperature of polymers. DSC analysis is also used to determine the specific heat capacity of polymers. The technique is used to study the thermal stability of polymers and to determine the effect of additives on the thermal properties of polymers.

Pharmaceutical Analysis

DSC analysis is used to study the thermal properties of pharmaceuticals. The technique is used to measure the glass transition temperature, melting temperature, and crystallization temperature of pharmaceuticals. DSC analysis is also used to determine the specific heat capacity of pharmaceuticals. The technique is used to study the thermal stability of pharmaceuticals and to determine the effect of additives on the thermal properties of pharmaceuticals.

DSC analysis is also used for other applications such as food analysis, environmental analysis, and material science. The technique is widely used in research and development, quality control, and process control.

Maintenance and Troubleshooting

Routine Maintenance

To ensure the optimal performance of your DSC Analysis Machine, it is important to perform routine maintenance. Here are some tasks that you should perform regularly:

- Clean the sample holder: After each use, clean the sample holder with a soft cloth or tissue paper to remove any residue. You can also use a mild solvent such as isopropyl alcohol to clean the sample holder. Make sure to dry it thoroughly before using it again.

- Check the calibration: It is important to check the calibration of your DSC Analysis Machine regularly to ensure accurate results. You can do this by running a standard material that has a known heat of fusion and comparing the results with the expected values. If there is a significant difference, you may need to recalibrate the machine.

- Inspect the furnace: Inspect the furnace regularly for any signs of damage or wear. If you notice any cracks or other damage, contact the manufacturer for repairs.

Common Issues and Fixes

Even with routine maintenance, you may encounter some issues with your DSC Analysis Machine. Here are some common issues and fixes:

- Baseline drift: If you notice that the baseline is drifting, it may be due to a dirty sample holder or contamination on the sample. Clean the sample holder and try again. If the problem persists, you may need to recalibrate the machine.

- Noisy baseline: If the baseline is noisy, it may be due to electrical interference. Make sure that the machine is properly grounded and that there are no other electrical devices nearby that could be causing interference.

- Poor resolution: If you are getting poor resolution, it may be due to a poorly calibrated machine or a sample that is too small. Check the calibration and try again. If the problem persists, try using a larger sample.

By performing routine maintenance and troubleshooting common issues, you can ensure that your DSC Analysis Machine is performing optimally and producing accurate results.