Demystifying DSC Equipment Price Tags: Differential Scanning Calorimeter Insights

Differential Scanning Calorimetry (DSC) Equipment is a thermal analysis technique used to measure the heat flow difference between a sample and a reference material under controlled temperature conditions. It involves subjecting the sample to a programmed temperature regimen (heating/cooling/isothermal) and observing how the heat flow between the sample and reference changes over time or temperature. This method provides insights into the sample’s heat absorption, release, specific heat variations, and other thermal behaviors during the temperature cycle. DSC calculates parameters such as enthalpy (heat absorbed or released) and characteristic temperatures (onset, peak, endpoint, etc.) to characterize these thermal effects.

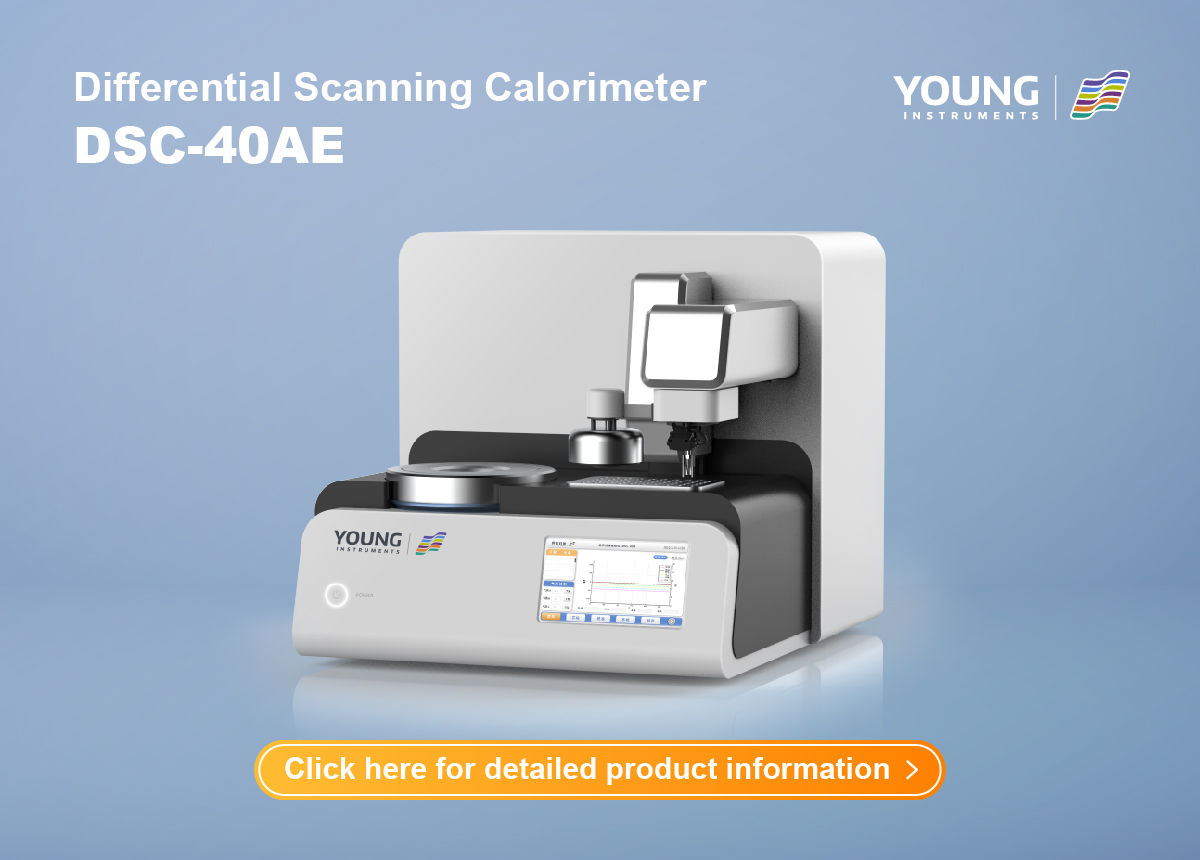

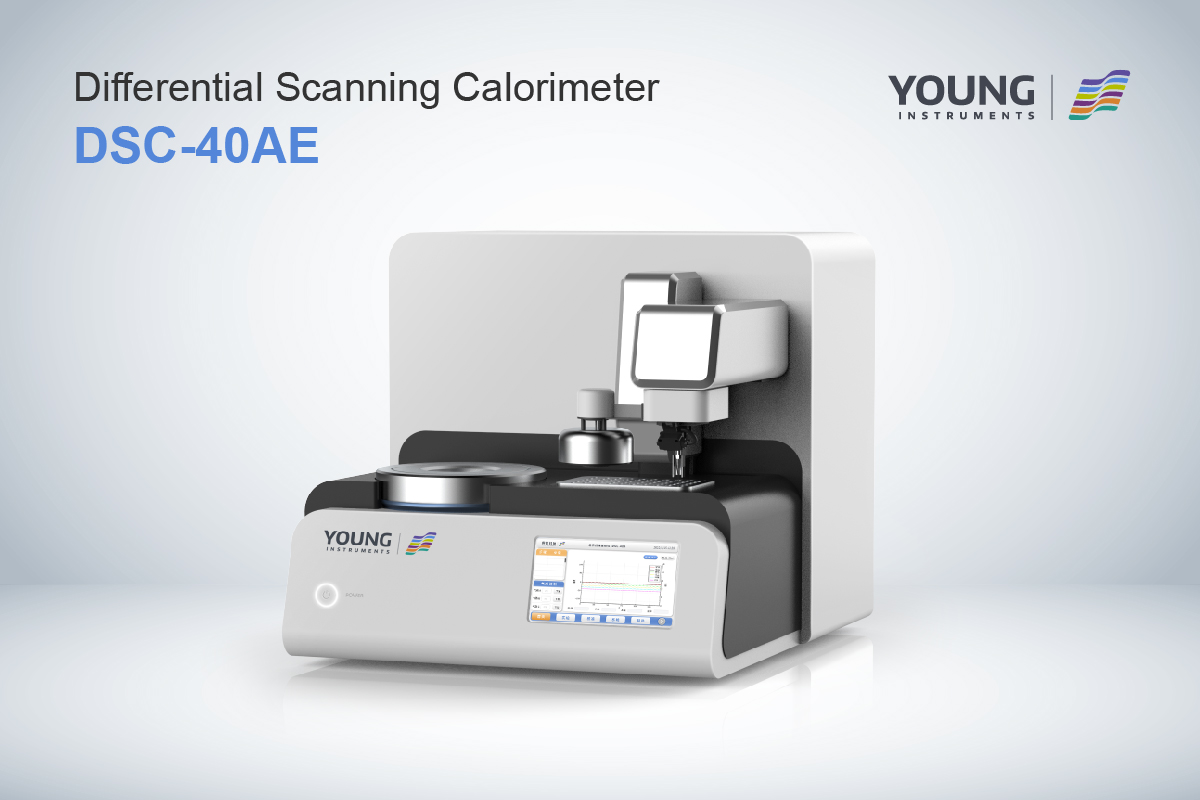

Introduction to DSC Product

Introduction to Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (DSC) is a pivotal thermal analysis method used to measure the heat flow difference between a sample and a reference under controlled temperature conditions. DSC techniques can be broadly classified into two types: heat flow type and power compensation type. The heat flow DSC is renowned for its stable baselines, high sensitivity, and cost-effective operation and maintenance. As DSC technology evolves, so does the precision and accuracy of thermal flow measurements, significantly advancing the field of thermal analysis.

Advantages of Heat Flow DSC

Heat flow DSC distinguishes itself through its design and operation. The main components are encased within a sealed cylindrical silver furnace chamber, optimizing heat transfer efficiency and reducing cross-interference between the sample and reference. This setup utilizes nickel-chromium alloy heat flow sensors and copper-nickel alloy pans, ensuring precise temperature measurements and robust performance in diverse thermal conditions. These features contribute to the method’s ability to provide stable, sensitive, and reliable data crucial for thermal analysis.

Zeal Instruments’ DSC-40AE Model

The DSC-40AE model from Zeal Instruments represents the forefront of DSC technology, featuring adjustable settings for physical properties at both the sample and reference ends, as well as varying heating rates. This calibration significantly improves resolution and sensitivity beyond what traditional DSC systems offer. The DSC-40AE excels in precise analysis of specific heat capacity, exothermic reactions, and other thermal properties due to its advanced algorithm for precise temperature and heat flow modulation. Its operating environment ranges from 5°C to 40°C with humidity levels below 85%. Phase transition temperature accuracy is ±0.1K, phase transition temperature reproducibility is ±0.02K, and enthalpy accuracy is ±1%.

Technical Specifications and Features

The DSC-40AE operates within a temperature control range from room temperature to 600°C, with a heating scan rate varying from 0.1K/min to 200K/min. It boasts an impressive data acquisition rate of 50Hz, which sharpens both sensitivity and resolution. The instrument’s structure is designed to maximize oxidation resistance at high temperatures, stabilize baselines, and optimize the signal-to-noise ratio. These capabilities make it highly effective for detailed analysis of phase transitions, specific heat, and enthalpy of reactions.

Practical Applications and Standards Compliance

Zeal Instruments’ DSC-40AE is equipped to handle a wide range of applications, from pharmaceuticals to polymers and from food science to materials research. It meets numerous international standards, including GB/T and ASTM, ensuring its applicability in global scientific and industrial settings. With features like ramp and isothermal temperature control modes and an intuitive high-definition touchscreen, the DSC-40AE stands as a versatile tool in any laboratory focused on material properties and transitions, providing detailed insights into the thermal behaviors of diverse materials.

DSC Applications

DSC plays a crucial role in determining various thermal properties critical to materials research and industry. These include glass transition temperature, thermal stability, oxidation resistance, crystallinity, reaction kinetics, melting enthalpy, crystallization temperature and duration, purity, gelation rate, boiling and melting points, and specific heat capacity.

Food

DSC’s versatility makes it indispensable across multiple industries. In food processing, it aids in monitoring lipid oxidation and other thermal changes during production and storage.

Plastics

Plastic manufacturers rely on DSC to evaluate polymer stability and behavior across different thermal environments.

Fine Chemical

Furthermore, pharmaceutical firms use DSC to assess compound purity and the crystalline structure of drug formulations, essential for ensuring efficacy and safety.

Energetic Materials

Beyond its conventional uses, DSC plays a pivotal role in studying intricate materials such as liquid crystals crucial for display technologies, as well as energetic materials used in explosives. These advanced applications underscore DSC’s pivotal role in advancing material sciences, providing in-depth insights into material behaviors at molecular levels under varying thermal conditions.

Applications of DSC in Specific Fields

Exploring Ionic Liquids

Differential Scanning Calorimetry (DSC) plays a crucial role in the study of ionic liquids, focusing on essential thermal properties such as glass transition temperatures and melting points. Researchers employ DSC to develop and evaluate stable co-equilibrium metal ionic liquids resistant to moisture and air. This advancement allows for the effective stabilization of lanthanide elements within these liquids, facilitating their application as propellants.

Advancing Liquid Crystal Technology

DSC serves as a key tool in determining the temperature ranges critical to liquid crystal phases, pivotal for enhancing liquid crystal materials. Studies involving various branched quaternary ammonium molecules have demonstrated that the length of the alkyl chain significantly impacts phase transitions. At temperatures near ambient, these materials undergo glass transitions, showcasing intriguing nematic and near-crystalline liquid crystal behaviors. Such insights are crucial for tailoring the functional properties of these molecular materials.

Characterizing Nanomaterial Dynamics

Utilizing DSC, researchers have uncovered unique properties of precursors used in synthetic nanodiamond production. These precursors not only contain free water molecules but also nano-sized water clusters within their pores. DSC analysis reveals distinct melting peaks for these water forms, enabling precise calculation of melting point differences (ΔT). This capability allows researchers to accurately assess the dispersity of different precursor types, surpassing the limitations of conventional characterization methods.

In Sum

Differential Scanning Calorimetry (DSC) is a pivotal analytical technique in materials science, offering profound insights into thermal properties critical for various applications. It enables the precise characterization and enhancement of materials, from stabilizing intricate ionic liquids for propulsion to refining liquid crystal materials essential in display technologies. Its widespread use across diverse sectors underscores its foundational importance in advancing both research and industrial applications. By delivering precise thermal analysis, DSC continues to foster innovation and advancements in materials science, facilitating the development of materials with optimized properties and functionalities.