Understanding the DSC Principle: A Key to Modern Thermal Analysis

When studying the thermal properties of materials, scientists often rely on highly precise instruments to gain valuable insights. One such instrument is the Differential Scanning Calorimeter (DSC). But what exactly is DSC, and why is it so crucial for research and industry? This article delves into the DSC Principle and applications of DSC, with a special focus on the innovations brought forth by the DSC-40A model, developed by Hangzhou Zeal Instruments Science & Technology Co., Ltd.

The Working DSC Principle: An Overview

How Does DSC Work?

The DSC principle is as follows: Differential Scanning Calorimetry (DSC) is a thermal analysis technique. It measures the energy absorbed or released by a sample when it is heated, cooled or held at a constant temperature. The purpose of DSC is to analyze material properties such as melting point, crystallization temperature, glass transition temperature and heat capacity. The basic principle is to compare the heat flow of a sample and a reference material under the same temperature program.

The Evolution of DSC Technology

In 1955, Boersma introduced an improved Differential Thermal Analysis (DTA) device, which established a stable linear relationship between the heat flow and temperature difference during the scanning process. This breakthrough led to the development of the “heat flux” type DSC, which allowed for the quantitative measurement of heat flow. Compared to the “power-compensation” type DSC, the heat flux type DSC offers smoother baselines, higher sensitivity, and lower maintenance costs. As DSC technology continued to evolve, new methods for measuring heat flow were developed, significantly enhancing the precision and accuracy of these instruments.

Components and Functionality of Heat Flux Type DSC

The core components of a heat flux type DSC are housed within a sealed cylindrical silver furnace. The heat is transferred to the sample through a heat flow sensor attached to a heating block. The heat flow sensor body is made of nickel-chromium alloy. Two raised platforms support the sample pan and reference pan. A copper-nickel alloy disc is welded to the back of the platform to form a thermocouple. The temperature of the sample and reference pans is accurately measured. During the scan, the furnace temperature changes at a constant rate. The heat flow difference between the sample pan and the reference pan is measured in real time. This heat flow difference is then corrected to obtain the true heat absorption or release of the sample.

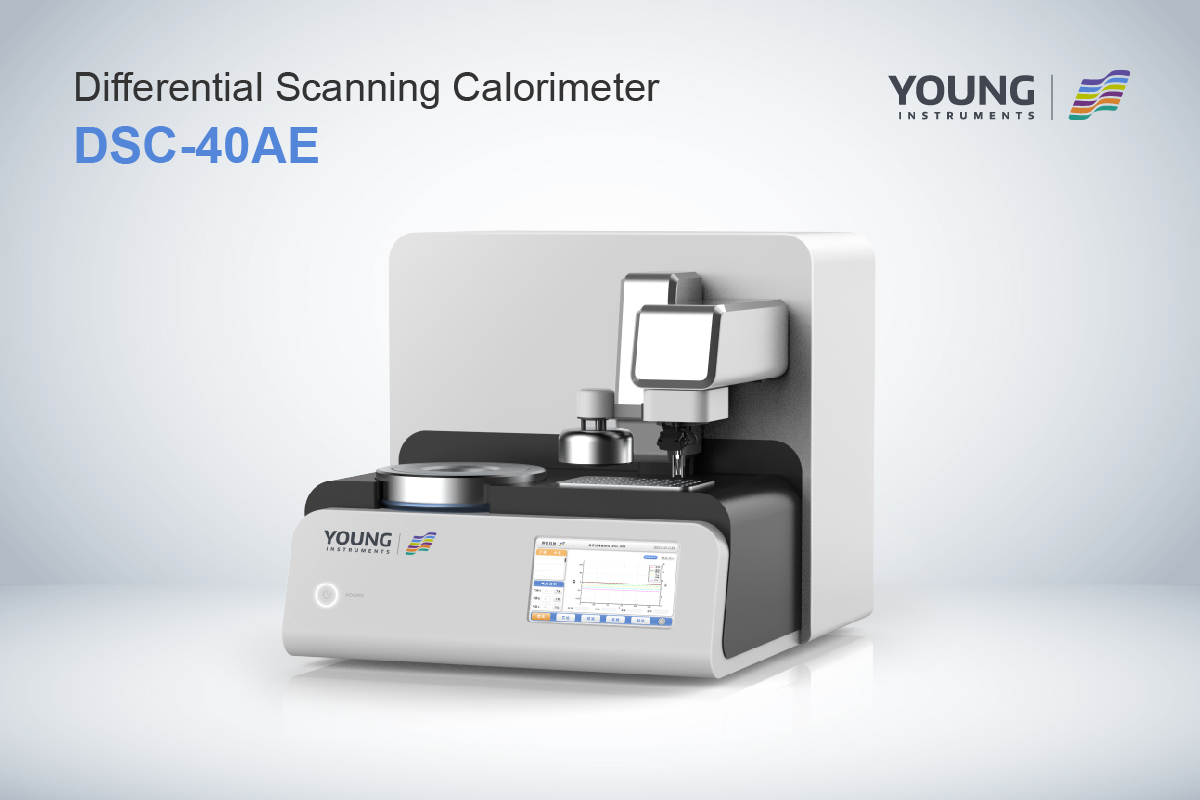

Advancements in DSC Technology: The DSC-40A Model

Enhanced Resolution and Sensitivity

The DSC-40A, developed by Hangzhou Zeal Instruments Science & Technology Co., Ltd., is based on the tower heat flow method principle. It is designed to measure the heat flow difference between the sample and reference sample per unit time under programmed temperature control. By accounting for and calibrating the physical characteristics and heating rate differences of the heat flow sensor between the reference and sample ends, the DSC-40A offers superior resolution and sensitivity compared to traditional DSCs.

Wide Range of Applications

This model is suitable for measuring a variety of thermal properties, including specific heat, glass transition temperature, melting point, crystallization temperature, crystallinity, melting enthalpy, crystallization enthalpy, crystallization kinetics, thermosetting plastic reaction heat, thermosetting plastic reaction kinetics, gelation conversion rate, etc. It is widely used in thermodynamics and kinetics research in polymer materials, biomedicine, inorganic non-metallic materials, petroleum, metal materials, energetic materials, food and other industries.

Key Features of the DSC-40A

- Tower Heat Flow Technology: The DSC-40A employs mature tower heat flow technology to enhance instrument resolution and sensitivity.

- Silver Furnace Design: The silver furnace ensures higher heat transfer efficiency and minimizes cross-interference between the reference and sample.

- Optimized Sensor Design: The nickel-chromium base improves high-temperature oxidation resistance and provides better dynamic response.

- Accurate Data Analysis: With the help of specialized algorithms, the DSC-40A modulates temperature and heat flow signals to obtain more precise data on specific heat capacity and reaction exotherm.

- High-Resolution Data Acquisition: The instrument’s data acquisition frequency reaches 50 Hz, effectively enhancing sensitivity and resolution.

Why Choose the DSC-40A?

A Leap in Thermal Analysis Capability

The DSC-40A model not only surpasses traditional DSCs in resolution and sensitivity but also offers greater reliability and precision. The tower heat flow principle design provides a steady and smooth baseline, reducing signal noise and ensuring more reliable results.

Designed for Easy Operation and Maintenance

The DSC-40A is built for user-friendly operation, featuring a high-definition touchscreen that allows for convenient instrument control and monitoring. Its robust design and optimized structure enhance baseline stability and increase the signal-to-noise ratio, making it an excellent choice for researchers and professionals seeking an efficient and reliable thermal analysis instrument.

Extensive Analytical Functions

The DSC-40A supports a wide range of analytical functions, including the determination of DSC onset point, start set point, end set point, baseline, heat flow peak, glass transition temperature, heat peak area, enthalpy values, peak temperature, extrapolated temperature, specific heat, and more. These features make it a versatile tool for detailed material characterization and analysis.

Product Specifications and Standards Compliance

Testing Standards Met by DSC-40A

The DSC-40A complies with a range of industry standards, including GB/T 22232, GB/T 28724, GB/T 19466.2, GB/T 28723, GB/T 19466.6, ASTM E2253, ASTM E793, ASTM E794, and ASTM E1269. This compliance ensures that the instrument meets the rigorous requirements for accuracy and repeatability in thermal analysis.

Technical Specifications

- Temperature Range: The instrument supports a wide temperature range, making it suitable for various types of thermal analysis.

- Sample Size: The DSC-40A uses milligram-level sample quantities, enabling precise measurements without wasting valuable materials.

- Data Acquisition Rate: With a data acquisition rate of up to 50 Hz, the DSC-40A captures thermal events with high sensitivity and precision.

Applications of DSC-40A in Research and Industry

Polymer Materials

The DSC-40A is extensively used to analyze the thermal properties of polymer materials, such as determining the glass transition temperature, crystallization behavior, and thermal stability. This information is crucial for developing new materials with tailored properties.

Biomedicine and Pharmaceuticals

In the biomedicine and pharmaceutical industries, the DSC-40A helps researchers understand the thermal properties of drugs and biological materials. It is particularly useful for studying the stability and compatibility of new formulations.

Metallurgy and Inorganic Materials

The instrument is also used in the study of metallic and inorganic materials. Used to measure phase changes, melting points and other key thermal properties that determine the performance and durability of these materials.

Conclusion: The Future of DSC Technology

The DSC-40A model from Hangzhou Zeal Instruments Science & Technology Co., Ltd., represents a significant advancement in thermal analysis technology. By combining the latest heat flow measurement technology with rugged design and comprehensive analysis capabilities. It sets new standards for accuracy, sensitivity and ease of use. The DSC-40A is a powerful tool in both academic research and industrial applications. Will continue to drive innovation and discovery in thermal analysis.

For more information on the DSC-40A and other advanced thermal analysis instruments, please visit Hangzhou Zeal Instruments Science & Technology Co., Ltd..