DSC Testing Machine: A Comprehensive Guide to Thermal Analysis

DSC Testing Machine is an essential instrument in material analysis, providing valuable insights into the thermal properties of various substances. These machines utilize the principles of differential scanning calorimetry to measure the heat flow associated with thermal transitions in a material. By accurately analyzing these thermal properties, DSC testing machines offer crucial data that can be applied across a wide range of industries and research fields.

The versatility of DSC testing machines makes them valuable tools for a variety of applications, including pharmaceuticals, polymers, food science, and more. Understanding the technical specifications, operating procedures, and maintenance of these instruments is vital for obtaining reliable and accurate results. By delving into the capabilities and operational aspects of DSC testing machines, you can harness their full potential for your specific analytical needs.

Key Takeaways

- DSC testing machines provide valuable insights into the thermal properties of materials.

- These instruments are widely used across various industries and research fields.

- Understanding the technical specifications and operational aspects is crucial for accurate analysis.

DSC Testing Machine Overview

If you are in the field of material science or engineering, you may have heard of a DSC testing machine. DSC stands for Differential Scanning Calorimetry, which is a thermal analysis technique used to measure the heat flow and temperature associated with thermal transitions in a material.

Principles of Operation

The DSC testing machine works by heating a sample and a reference material at a controlled rate, while simultaneously measuring the heat flow between them. As the temperature changes, the sample undergoes thermal transitions such as melting, crystallization, glass transitions, curing, and decomposition. These transitions cause changes in the heat flow, which can be recorded by the DSC machine.

Key Components

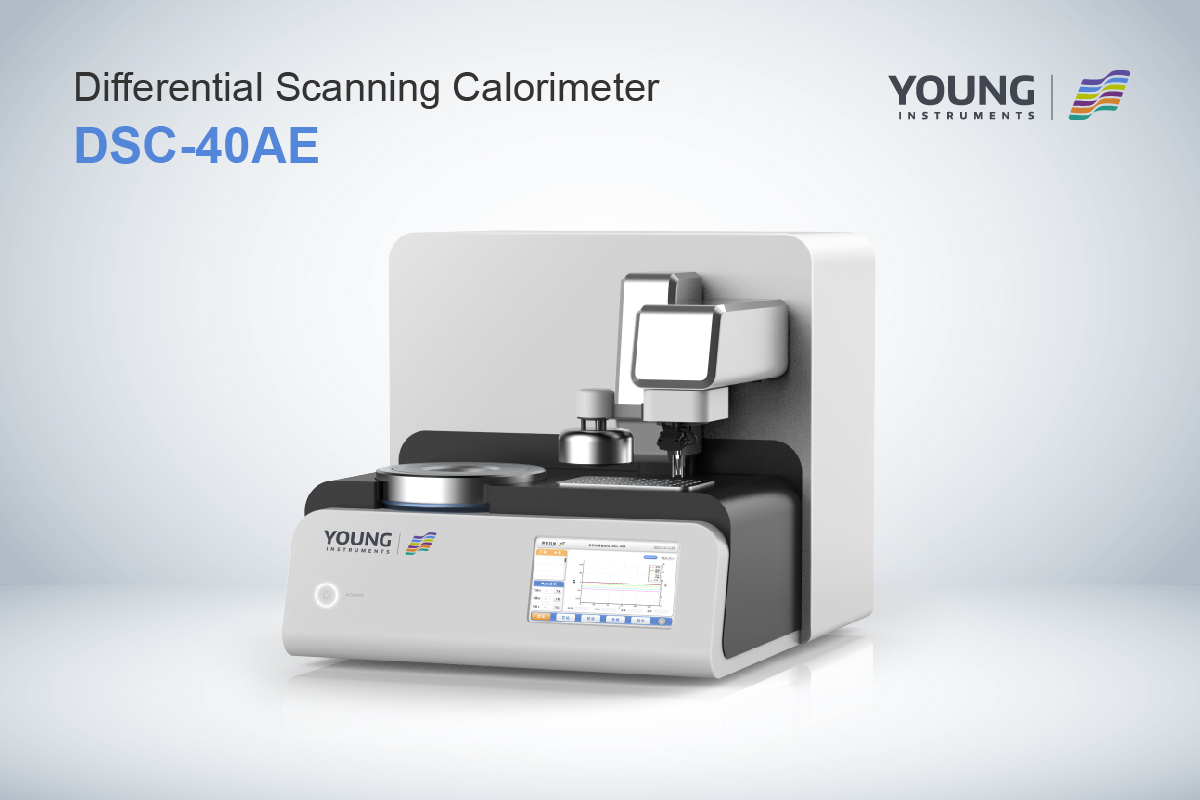

The DSC testing machine consists of several key components, including the sample holder, furnace, temperature controller, and data acquisition system. The sample holder is where the sample and reference material are placed. The furnace is responsible for heating the sample and reference at a controlled rate. The temperature controller maintains a constant temperature and controls the rate of heating. The data acquisition system records the heat flow and temperature data, which can be used to analyze the thermal behavior of the sample.

In summary, the DSC testing machine is a powerful tool used to investigate the thermal properties of materials. By measuring heat flow and temperature changes associated with thermal transitions, it can provide valuable information about a material’s behavior under different conditions. With its key components and principles of operation, the DSC testing machine is an essential tool in the field of material science and engineering.

Applications of DSC Testing

DSC Testing Machine is a versatile thermal analysis technique that can be used to evaluate various qualities in specimens. It allows monitoring of glass transition temperatures, fusion and crystallization occurrences, and other chemical reactions. DSC Testing Machine is a valuable tool in the fields of Material Characterization, Quality Control, and Research and Development.

Material Characterization

DSC Testing Machine is used to characterize materials by measuring their thermal properties. It is used to determine the specific heat capacity, temperature of phase changes, and melting points of a particular sample material. These properties can be commonly classified as thermal transitions. DSC Testing Machine is useful in the characterization of polymers, composites, and other materials.

Quality Control

DSC Testing Machine is a valuable tool in quality control. It is used to evaluate the quality of materials used in manufacturing processes. It can be used to identify the presence of impurities and contaminants in materials. DSC Testing Machine is also used to ensure the consistency of materials used in manufacturing processes.

Research and Development

DSC Testing Machine is an important tool in research and development. It is used to investigate, select, compare, and evaluate the end-use performance of materials in research, quality control, and production applications. DSC Testing Machine is also used to develop new materials and to improve the performance of existing materials. It is a valuable tool in the development of new products and technologies.

In conclusion, DSC Testing Machine is a versatile thermal analysis technique that can be used to evaluate various qualities in specimens. It is a valuable tool in the fields of Material Characterization, Quality Control, and Research and Development.

Technical Specifications

Temperature Range

The DSC testing machine is capable of measuring the temperature range of -150°C to 700°C. This range can be adjusted based on the specific needs of the material being tested. The temperature range is important because it allows for the identification of thermal transitions that occur at different temperatures, such as melting, crystallization, glass transition, and chemical reactions.

Sensitivity

The sensitivity of the DSC testing machine is critical for accurate measurements. The machine is capable of detecting small changes in heat flow and temperature, with a sensitivity of up to 0.1 µW. This level of sensitivity is important for detecting small thermal transitions, such as those that occur in polymers, pharmaceuticals, and other materials.

Calibration Standards

The DSC testing machine is calibrated using standard materials, such as indium and zinc. These materials have well-defined melting temperatures and heat of fusion values, which are used to calibrate the machine. The calibration process ensures that the DSC machine is accurate and reliable, providing consistent results over time.

In summary, the DSC testing machine is a powerful tool for analyzing the thermal properties of materials. With a temperature range of -150°C to 700°C, a sensitivity of up to 0.1 µW, and calibration using standard materials, the DSC machine provides accurate and reliable measurements of thermal transitions in a wide range of materials.

Operating Procedures

Operating a DSC testing machine requires careful attention to detail and adherence to established procedures. In this section, we will outline the steps necessary for proper sample preparation, test execution, and data interpretation.

Sample Preparation

Before beginning the test, it is essential to prepare the sample properly. The sample should be clean, dry, and free from any contaminants that could affect the results. The sample size should be consistent with the recommended guidelines for the specific DSC machine being used.

Test Execution

To execute the test, you will need to follow the steps outlined in the DSC machine’s operating manual. Typically, the process involves heating and cooling the sample at a controlled rate while measuring the heat flow.

During the test, it is essential to monitor the test parameters carefully and record the data accurately. Any deviations from the recommended settings or procedures could affect the accuracy of the results.

Data Interpretation

Once the test is complete, it is time to interpret the data. The data will typically include a thermogram that shows the heat flow as a function of temperature.

To interpret the data, you will need to compare the thermogram to reference data or known standards. This process will help you identify the specific characteristics of the sample, such as melting point, glass transition temperature, and heat of fusion.

In conclusion, following the proper operating procedures for a testing machine is critical to obtaining accurate and reliable results. By carefully preparing the sample, executing the test correctly, and interpreting the data accurately, you can ensure that your DSC testing is effective and informative.