Dust Explosion Screening: Understanding the Basics

If you work in an industry that involves handling dust or powders, it’s important to be aware of the risk of dust explosions. These types of explosions can cause serious damage and even loss of life, so it’s crucial to take steps to prevent them from occurring. One of the ways to do this is through dust explosion screening.

Dust explosion screening involves testing dust samples to determine their potential to cause an explosion. This is important because not all dust is created equal – some types are more explosive than others. By testing your dust samples, you can identify potential hazards and take steps to mitigate them. This can include modifying your processes or equipment or using different materials that are less likely to cause explosions.

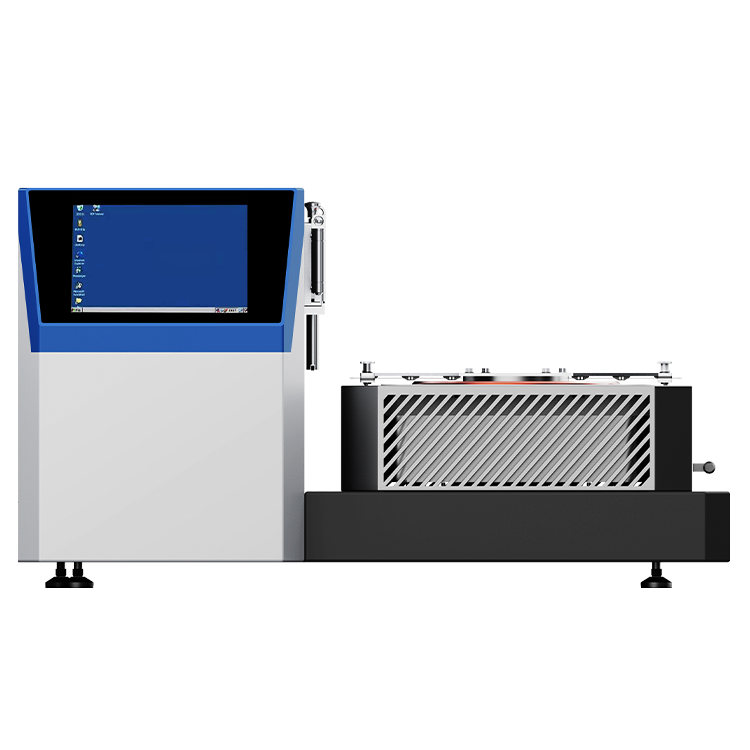

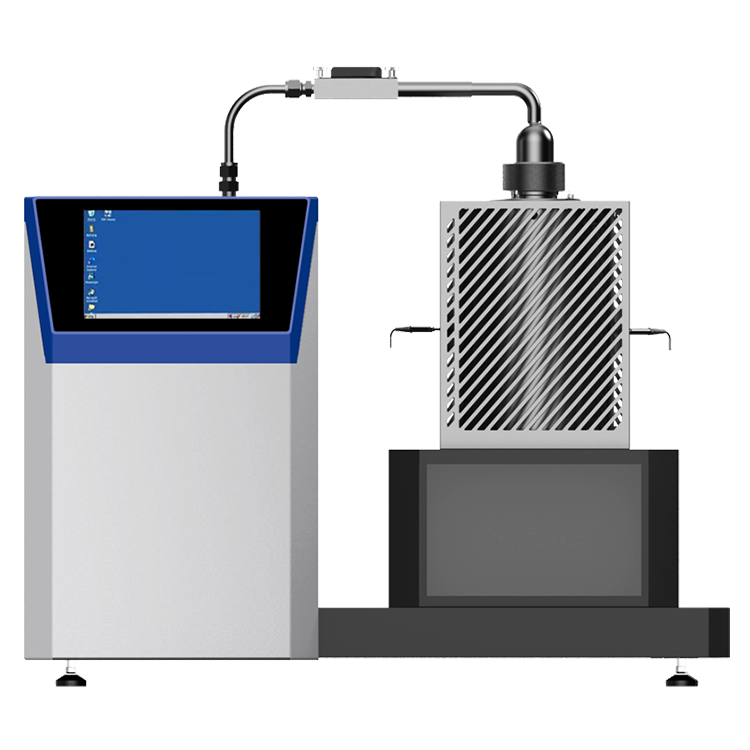

There are a variety of different tests that can be used for dust explosion screening, including the 20-Liter Sphere Test, the Limiting Oxygen Concentration Test, and the Minimum Explosible Concentration Test. Each test has its own strengths and weaknesses, so it’s important to choose the right test for your specific needs. By conducting these tests, you can gain a better understanding of the risks associated with your dust and take steps to prevent explosions from occurring.

Fundamentals of Dust Explosions

Defining Dust Explosions

Dust explosions are a type of explosion that occurs when combustible dust particles are suspended in the air and come into contact with an ignition source, such as a spark or flame. These explosions can cause significant damage to equipment and facilities, as well as pose a serious safety risk to personnel.

Mechanism of Ignition

The mechanism of ignition for dust explosions can vary depending on the type of dust and the conditions present. However, the most common mechanism of ignition is a spark or flame. This can be caused by a variety of sources, including static electricity, hot surfaces, welding, and electrical equipment.

Conditions for Combustion

For a dust explosion to occur, three conditions must be present: fuel, oxygen, and an ignition source. The fuel is provided by combustible dust particles, which can come from a variety of sources, including wood, coal, grain, and chemicals. The oxygen is provided by the air, which is present in most industrial settings. Finally, the ignition source can come from a variety of sources, including sparks, flames, and hot surfaces.

To prevent dust explosions, it is important to eliminate or control one or more of these conditions. This can be done by implementing dust collection systems, using non-sparking tools, and controlling the temperature and humidity levels in the facility. Additionally, it is important to provide training to personnel on the hazards of combustible dust and how to prevent dust explosions.

By understanding the fundamentals of dust explosions, you can take steps to prevent these dangerous and costly incidents from occurring in your facility.

Characteristics of Combustible Dust

When screening for combustible dust, it is important to understand the characteristics of the dust in question. The following subsections describe some of the key characteristics that should be considered.

Particle Size and Shape

Particle size and shape are important factors in determining the combustibility of a dust. Finer particles are more likely to ignite and propagate a flame than larger particles. Additionally, irregularly shaped particles can create more surface area, increasing the likelihood of combustion.

Moisture Content

Moisture content is another important factor to consider when screening for combustible dust. Moisture can help to suppress dust explosions by preventing dust particles from becoming airborne. However, too much moisture can also create a risk by promoting the growth of microorganisms that can produce combustible gases.

Chemical Composition

The chemical composition of a dust can also affect its combustibility. Some chemicals are more reactive than others and can ignite more easily. Additionally, certain chemicals can create more toxic byproducts when burned, increasing the risk to workers and the environment.

By understanding these characteristics, you can better identify and mitigate the risks associated with combustible dust.

Dust Explosion Hazard Assessment

When it comes to dust explosion screening, the first step is to conduct a thorough hazard assessment. This assessment will help you identify hazardous locations, evaluate explosion severity, and determine whether the dust is in a layer or suspended in the air.

Identifying Hazardous Locations

The first step in a dust explosion hazard assessment is to identify the areas where dust may accumulate. This includes not only the obvious areas, such as floors and work surfaces, but also areas that may be less obvious, such as ventilation systems, ductwork, and equipment. You should also consider the materials that are present in these areas, as some materials are more likely to create explosive dust clouds than others.

Evaluating Explosion Severity

Once you have identified the hazardous locations, the next step is to evaluate the severity of a potential explosion. This involves determining the maximum explosion pressure and the maximum rate of pressure rise that could occur in the event of an explosion. This information can then be used to determine the appropriate explosion protection measures, such as explosion vents or suppression systems.

Dust Layer vs. Suspended Dust

Finally, it is important to determine whether the dust is in a layer or suspended in the air. Dust layers are typically less dangerous than suspended dust, as they are less likely to create explosive dust clouds. However, dust layers can still be hazardous if they are disturbed, such as by a spark or other ignition source. Suspended dust, on the other hand, is much more dangerous, as it can create explosive dust clouds that can travel throughout a facility.

By conducting a thorough dust explosion hazard assessment, you can identify potential hazards and take appropriate steps to protect your facility and your employees.

Preventive and Mitigation Strategies

Dust explosions can cause significant damage to your facility, harm employees, and even lead to fatalities. Therefore, it is essential to implement preventive and mitigation strategies to reduce the risk of dust explosions.

Explosion Prevention Measures

Explosion prevention measures involve eliminating one or more elements that are necessary for a dust explosion to occur. The three primary elements are fuel, oxygen, and an ignition source. You can eliminate fuel by controlling dust accumulation, using non-combustible materials, or substituting combustible materials with non-combustible ones. You can eliminate oxygen by using inert gases or reducing air supply. Lastly, you can eliminate ignition sources by using explosion-proof equipment, controlling electrostatic discharge, or avoiding welding and cutting activities near combustible materials.

Explosion Protection Systems

Explosion protection systems are designed to contain and suppress explosions. These systems include explosion vents, explosion suppression systems, and explosion isolation systems. Explosion vents are designed to relieve pressure during an explosion, while explosion suppression systems are designed to detect and extinguish an explosion before it spreads. Explosion isolation systems are designed to prevent explosions from spreading between interconnected equipment.

Housekeeping and Control Procedures

Housekeeping and control procedures involve maintaining a clean and organized workplace to reduce the risk of dust accumulation and ignition. You should implement a regular cleaning schedule to remove combustible dust and debris from floors, equipment, and other surfaces. You should also control and monitor the use of equipment that generates dust, such as grinders, sanders, and saws. Lastly, you should train employees on the hazards of combustible dust and the proper procedures for handling and disposing of it.

By implementing these preventive and mitigation strategies, you can significantly reduce the risk of dust explosions in your facility. However, it is essential to assess your facility’s specific hazards and consult with experts to develop a comprehensive dust explosion screening plan.

Regulatory Standards and Guidelines

When it comes to preventing dust explosions, there are a number of regulatory standards and guidelines that companies must follow. These standards and guidelines are designed to help minimize the risk of dust explosions and ensure the safety of workers and the general public.

National and International Regulations

There are a number of national and international regulations that companies must follow to prevent dust explosions. For example, in the United States, the Occupational Safety and Health Administration (OSHA) has established guidelines for the handling of combustible dusts. OSHA’s guidelines include recommendations for conducting hazard assessments, implementing engineering controls, and providing employee training.

Similarly, the European Union has established a number of regulations to prevent dust explosions. The ATEX Directives, for example, require companies to conduct risk assessments, implement control measures, and provide employee training.

Industry-Specific Guidelines

In addition to national and international regulations, there are also industry-specific guidelines that companies must follow to prevent dust explosions. For example, the National Fire Protection Association (NFPA) has established a number of guidelines for specific industries, such as the wood products industry, the agricultural industry, and the food industry.

These guidelines are designed to help companies identify potential hazards, implement control measures, and provide employee training. They may also include specific requirements for equipment design, installation, and maintenance.

Overall, it is important for companies to stay up-to-date on the latest regulatory standards and guidelines to ensure the safety of their workers and the general public. By following these guidelines, companies can help minimize the risk of dust explosions and ensure a safe working environment.