EV Battery Abuse Testing: Methods and Importance

If you are interested in electric vehicles, then you are likely aware that the battery is one of the most important components of an EV. The battery is what powers the vehicle, and the performance of the battery can have a significant impact on the overall performance of the vehicle. However, batteries can be subject to abuse, which can damage the battery and reduce its performance. This is why EV battery abuse testing is such an important part of the EV design and manufacturing process.

EV battery abuse testing is a process that involves subjecting the battery to a variety of extreme conditions to determine how it will perform under stress. This can include exposing the battery to high temperatures, subjecting it to physical shock, and overcharging or discharging the battery. By testing the battery under these extreme conditions, manufacturers can identify potential weaknesses in the battery and make improvements to the design to ensure that it is as safe and reliable as possible.

There are a variety of different standards and regulations that govern EV battery abuse testing, and it is important for manufacturers to comply with these standards to ensure that their batteries are safe and reliable. Some of the most commonly used standards include SAE J2464, SAE J2929, UN 38.3, and ISO 12405. By complying with these standards, manufacturers can ensure that their batteries are safe and reliable, and that they meet the needs of their customers.

Fundamentals of EV Battery Abuse Testing

As an EV battery manufacturer, it is crucial to ensure that your batteries are safe and reliable. One way to do this is by performing abuse testing. Abuse testing is a set of tests that simulate extreme conditions to which a battery may be exposed during its lifetime. These tests are designed to identify potential safety hazards and to evaluate the battery’s performance under adverse conditions.

The most common types of abuse testing for EV batteries include mechanical abuse, electrical abuse, thermal abuse, and environmental abuse. Mechanical abuse testing involves dropping the battery, crushing it, or puncturing it to simulate accidents or rough handling. Electrical abuse testing involves overcharging, over-discharging, or short-circuiting the battery to simulate electrical faults. Thermal abuse testing involves exposing the battery to high temperatures, low temperatures, or rapid temperature changes to simulate extreme weather conditions. Environmental abuse testing involves exposing the battery to humidity, salt spray, or other environmental factors to simulate corrosion or degradation.

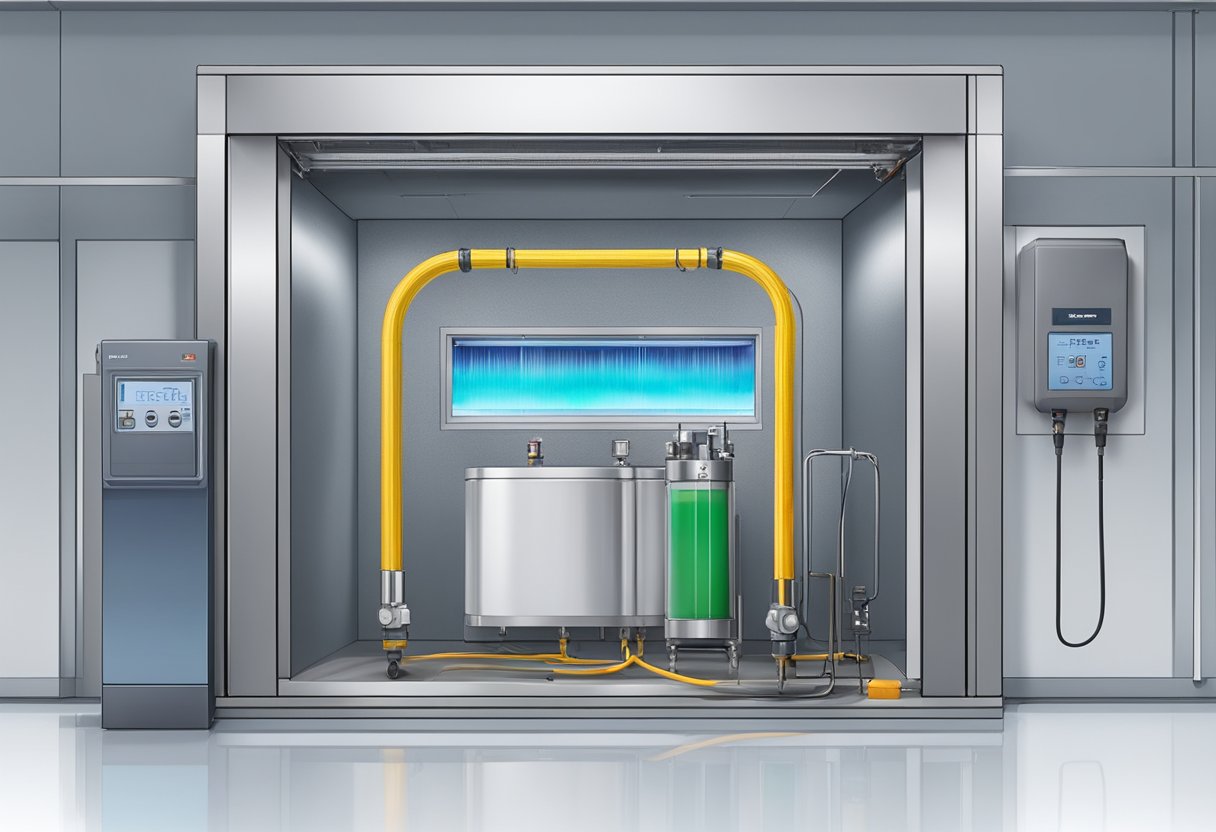

To perform abuse testing, you will need specialized equipment and facilities. You may also need to comply with international standards and regulations, such as those set by the United Nations, the International Electrotechnical Commission, or the Society of Automotive Engineers. These standards and regulations specify the test procedures, test conditions, and pass/fail criteria for each type of abuse test.

It is important to note that abuse testing is not a one-time event. As battery technology evolves and new safety hazards are identified, you may need to update your abuse testing procedures and standards. You should also perform regular quality control checks to ensure that your batteries meet the required safety and performance standards.

In summary, EV battery abuse testing is a critical step in ensuring that your batteries are safe and reliable. By simulating extreme conditions, you can identify potential safety hazards and evaluate the battery’s performance under adverse conditions. To perform abuse testing, you will need specialized equipment and facilities and must comply with international standards and regulations. Regular quality control checks are also necessary to ensure that your batteries meet the required safety and performance standards.

Mechanical Abuse Testing

Mechanical abuse testing is a crucial part of EV battery testing. It involves subjecting the battery to various mechanical stresses to assess its structural integrity and durability. There are three main types of mechanical abuse tests: Crush tests, impact tests, and penetration tests.

Crush Tests

Crush tests simulate real-world operating conditions and evaluate the battery’s resistance to physical damage and mechanical abuse. During the test, the battery is compressed between two plates until it deforms or ruptures. The test measures the force required to crush the battery and the deformation of the battery.

Impact Tests

Impact tests simulate situations where the battery is dropped or hit by an object. The test evaluates the battery’s resistance to impact and its ability to withstand mechanical shocks. During the test, the battery is dropped from a specified height onto a hard surface, and the impact force is measured.

Penetration Tests

Penetration tests simulate situations where the battery is punctured by a sharp object. The test evaluates the battery’s resistance to penetration and its ability to withstand mechanical damage. During the test, a sharp object is driven into the battery, and the force required to penetrate the battery is measured.

In conclusion, mechanical abuse testing is an essential part of EV battery testing. It helps ensure that the battery can withstand real-world operating conditions and mechanical abuse. By subjecting the battery to various mechanical stresses, engineers can identify potential weaknesses and improve the battery’s design and construction.

Thermal Abuse Testing

Thermal abuse testing is a crucial aspect of EV battery testing. It involves exposing the battery to high temperatures to determine its safety and performance under extreme conditions. There are two types of thermal abuse tests: overheating tests and thermal runaway tests.

Overheating Tests

Overheating tests are designed to simulate the effects of high temperatures on the battery. During this test, the battery is exposed to high temperatures to determine its ability to withstand extreme heat. The test is performed by placing the battery in an oven and gradually increasing the temperature until it reaches a predetermined level. The battery is then left at that temperature for a specific amount of time before it is removed from the oven and allowed to cool.

Thermal Runaway Tests

Thermal runaway tests are designed to simulate the effects of a battery malfunction that results in a rapid increase in temperature. During this test, the battery is exposed to a small heat source to initiate a thermal runaway event. The temperature of the battery is then monitored as it continues to heat up until it reaches a critical point. The test is designed to determine the battery’s ability to prevent thermal runaway and to minimize the risk of fire or explosion.

Thermal abuse testing is an essential part of EV battery testing, and it is necessary to ensure the safety and reliability of EV batteries. By subjecting batteries to high temperatures, manufacturers can identify potential issues and make necessary improvements to enhance the safety and performance of their products.

Electrical Abuse Testing

When it comes to EV battery abuse testing, electrical abuse testing is an important aspect. This testing is designed to evaluate the battery’s ability to withstand various electrical abuse scenarios.

Overcharge Tests

One type of electrical abuse testing is overcharge testing. During this test, the battery is charged to a voltage higher than its maximum recommended level. This test is designed to evaluate the battery’s ability to withstand overcharging scenarios. Overcharging can lead to thermal runaway, which can result in a fire or explosion.

Short Circuit Tests

Another type of electrical abuse testing is short circuit testing. During this test, a short circuit is created within the battery to evaluate its ability to withstand this type of scenario. Short circuits can occur due to internal or external factors, and can lead to thermal runaway.

In addition to these tests, there are other types of electrical abuse testing that can be performed to evaluate the battery’s ability to withstand abuse scenarios. It is important to note that these tests are designed to evaluate worst-case scenarios and should not be attempted outside of a controlled testing environment.

Overall, electrical abuse testing is an important aspect of EV battery abuse testing. By evaluating the battery’s ability to withstand various electrical abuse scenarios, manufacturers can ensure that their batteries are safe and reliable for use in electric vehicles.

Environmental Abuse Testing

When it comes to testing electric vehicle (EV) batteries, it’s important to ensure that they can withstand various environmental conditions. Environmental abuse testing is designed to simulate the harsh conditions that batteries may encounter during their lifespan. Here are two common types of environmental abuse testing:

Humidity Exposure

Humidity exposure testing is used to evaluate the ability of batteries to withstand exposure to high humidity levels. During this test, the battery is exposed to high levels of humidity for a set period of time. The goal is to determine if the battery can maintain its performance and functionality even when exposed to high levels of humidity.

Salt Spray Tests

Salt spray tests are used to assess the ability of batteries to withstand exposure to saltwater and other corrosive substances. During this test, the battery is exposed to a saltwater mist for a set period of time. The goal is to determine if the battery can maintain its performance and functionality even when exposed to corrosive substances.

Overall, environmental abuse testing is an important part of the battery testing process. By subjecting batteries to harsh environmental conditions, manufacturers can ensure that their products are capable of withstanding the rigors of real-world use.

Regulatory Standards and Compliance

When it comes to EV battery abuse testing, regulatory standards and compliance are of utmost importance. These standards and regulations are in place to ensure the safety and reliability of EV batteries, and to prevent any potential hazards that may arise from their use.

In North America, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that specify safety requirements for motor vehicles and motor vehicle equipment. These standards cover various aspects of EV battery safety, including crashworthiness, occupant protection, and electrical safety.

In Europe, the European Union has established the General Safety Regulation (GSR) which sets out safety requirements for motor vehicles and their components. The GSR covers various aspects of EV battery safety, including crashworthiness, occupant protection, and electrical safety.

In Asia, there are various regulations and standards that cover EV battery safety, including the Chinese GB/T standards, the Japanese JIS standards, and the Korean KS standards. These regulations and standards cover various aspects of EV battery safety, including electrical safety, environmental performance, and durability.

It is essential to ensure that EV batteries comply with these regulatory standards to ensure their safety and reliability. Failure to comply with these standards can result in costly recalls, legal liabilities, and reputational damage. Therefore, it is recommended that EV battery manufacturers work with third-party testing and certification organizations to ensure compliance with these regulatory standards.