Heat Flow Measurement: Understanding the Basics

If you are interested in understanding how heat flows through materials, then you need to learn about heat flow measurement. Heat flow measurement is the process of measuring the amount of heat that flows through a material over time. This is an important concept in many different fields, including engineering, physics, and materials science.

There are several different methods of measuring heat flow, including the heat flow meter method, the guarded hot plate method, and the transient plane source method. Each of these methods has its own advantages and disadvantages, and the choice of method will depend on the specific application. For example, the heat flow meter method is often used to measure the thermal conductivity of building materials, while the transient plane source method is commonly used to measure the thermal conductivity of polymers and other materials that are difficult to measure using other methods.

Fundamentals of Heat Flow

When it comes to measuring heat flow, there are a few fundamental concepts that you need to understand. In this section, we will cover two of the most important concepts: thermal gradient and Fourier’s Law.

Thermal Gradient

Thermal gradient is the change in temperature over a distance. It is measured in units of temperature per unit length, such as degrees Celsius per meter. When there is a temperature difference between two points in a material, heat will flow from the hotter point to the colder point. The rate of heat flow is proportional to the thermal gradient and the thermal conductivity of the material.

Fourier’s Law

Fourier’s Law describes the rate of heat flow through a material in terms of the thermal gradient and the thermal conductivity of the material. It states that the rate of heat flow is proportional to the thermal gradient and the thermal conductivity, and is given by the equation:

q = -kA(dT/dx)

where q is the heat flow rate, k is the thermal conductivity, A is the cross-sectional area of the material, dT is the temperature difference across the material, and dx is the distance over which the temperature difference occurs.

Thermal conductivity is a measure of how well a material conducts heat. It is measured in units of watts per meter per degree Celsius (W/m°C). The thermal conductivity of a material depends on its composition, density, and temperature.

To measure heat flow, you need to measure the temperature difference across a material and the thermal conductivity of the material. This can be done using a thermal conductivity measurement device, such as a heat flux sensor or a thermal conductivity meter. These devices work by measuring the temperature difference across a material and the heat flow rate, and then calculating the thermal conductivity using Fourier’s Law.

Overall, understanding the fundamentals of heat flow is essential for accurately measuring heat flow and designing effective heat transfer systems. By understanding thermal gradient and Fourier’s Law, you can better understand how heat flows through materials and how to measure it.

Measurement Techniques

Heat flow measurement techniques can be classified into two main categories: steady-state methods and transient methods.

Steady-State Methods

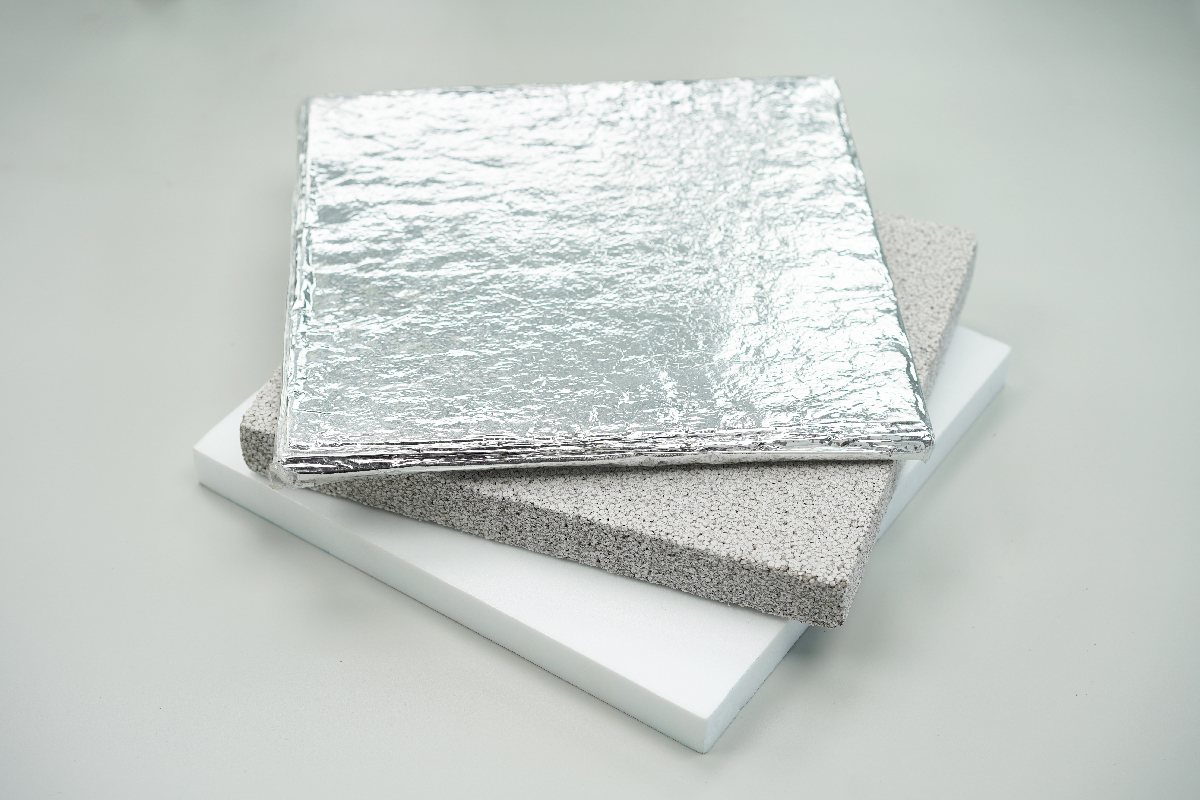

Steady-state methods involve measuring the temperature difference across a sample of known thickness and area under steady-state conditions, where the heat flow is constant. The most common steady-state method is the heat flow meter method, which measures the thermal conductivity of a material by determining the heat flow through a sample of known thickness and area.

The heat flow meter method involves placing a sample of known thickness between two plates, one of which is heated and the other is cooled. The temperature difference across the sample is measured, and the heat flow through the sample is calculated using a heat flow meter. The thermal conductivity of the sample is then calculated using the heat flow, sample thickness, and temperature difference.

Transient Methods

Transient methods involve measuring the temperature response of a sample to a sudden change in temperature or heat flow. The most common transient method is the transient plane source (TPS) method, which measures the thermal conductivity of a material by applying a heat pulse to one side of a thin disc-shaped sample and measuring the temperature response on the opposite side.

The TPS method involves placing a thin disc-shaped sample between two plates, one of which is heated and the other is cooled. A heat pulse is applied to the sample, and the temperature response on the opposite side is measured using a thermocouple. The thermal conductivity of the sample is then calculated using the heat pulse, sample thickness, and temperature response.

Thermal conductivity measurement devices such as the heat flow meter and TPS are widely used in various industries, including the automotive, aerospace, and electronics industries. These devices provide accurate and reliable measurements of thermal conductivity, which is essential for the design and development of thermal management systems in these industries.

Instrumentation and Devices

When it comes to measuring heat flow, several types of instrumentation and devices can be used. In this section, we will discuss the most common ones: Heat Flow Meters, Thermocouples, and Infrared Thermography.

Heat Flow Meters

Heat Flow Meters are devices that measure the amount of heat that is flowing through a material. They work by measuring the temperature difference between two surfaces of the material and the thermal conductivity of the material. Heat Flow Meters are commonly used in building and construction industries to measure the insulation properties of materials.

Thermocouples

Thermocouples are temperature sensors that are made up of two different metals that are joined together at one end. When the temperature at the junction changes, a voltage is generated that is proportional to the temperature difference. Thermocouples are commonly used in industrial applications to measure temperature in harsh environments.

Infrared Thermography

Infrared Thermography is a non-contact temperature measurement technique that uses infrared radiation to measure the temperature of an object. Infrared cameras are used to capture the infrared radiation emitted by an object, which is then converted into a temperature reading. Infrared Thermography is commonly used in electrical and mechanical maintenance to identify hot spots in equipment.

Overall, there are many different types of instrumentation and devices that can be used for heat flow measurement, including Thermal Conductivity Measurement Devices. The choice of device depends on the specific application and the accuracy required.

Calibration and Standards

When it comes to heat flow measurement, calibration and standards are essential to ensure accurate and reliable results. This section will cover the reference materials and calibration procedures used in heat flow measurement.

Reference Materials

Reference materials are used to calibrate heat flow measurement instruments and ensure that they are accurate. The National Institute of Standards and Technology (NIST) provides a range of reference materials for this purpose. These materials are traceable to international standards and are used to calibrate heat flow meters, thermal conductivity meters, and other heat flow measurement instruments.

Calibration Procedures

Calibration procedures for heat flow measurement instruments vary depending on the type of instrument being used. However, there are some general steps that are typically followed:

- Establish a reference temperature gradient using a known heat source and heat sink.

- Measure the heat flow using the instrument being calibrated.

- Compare the measured heat flow to the known heat flow.

- Adjust the instrument to ensure that it is accurate.

Calibration procedures should be performed regularly to ensure that heat flow measurement instruments remain accurate over time. It is recommended that instruments be calibrated at least once a year.

In addition to regular calibration, it is important to follow established standards for heat flow measurement. The ASTM C518 standard test method is commonly used for steady-state thermal transmission properties of building materials and other materials. This standard establishes a procedure for measuring the heat flow through a material under steady-state conditions.

Overall, calibration and standards are critical to ensuring accurate and reliable heat flow measurement. By using reference materials and following established calibration procedures and standards, you can be confident in the accuracy of your heat flow measurement results.

Applications and Considerations

When it comes to heat flow measurement, there are a variety of applications and considerations to keep in mind. Here, we’ll explore a few of the most important ones.

Industrial Applications

One of the most common applications of heat flow measurement is in industrial settings. For example, thermal conductivity measurement devices are often used to monitor the temperature of industrial equipment and processes. This can help ensure that everything is operating within safe and efficient parameters, and can also help identify potential issues before they become major problems.

Environmental Impact

Another important consideration when it comes to heat flow measurement is the potential environmental impact. For example, some measurement devices may require the use of hazardous materials or chemicals, which can be harmful to the environment if not handled properly. It’s important to carefully consider the environmental impact of any measurement device before using it.

Accuracy and Precision

Finally, accuracy and precision are crucial considerations when it comes to heat flow measurement. In order to get accurate and reliable readings, it’s important to use a high-quality measurement device that is calibrated properly. Additionally, it’s important to carefully follow all instructions and protocols when using the device to ensure that you get the most accurate readings possible.

Overall, heat flow measurement is an important process that has a wide range of applications and considerations. Whether you’re working in an industrial setting or simply trying to monitor the temperature in your home, it’s important to choose the right measurement device and use it properly to ensure accurate and reliable readings.