HFM 510A: Precision Heat Flow Meter Equipment

Heat Flow Meter Equipment, such as the HFM 510A model, are critical instruments designed to measure the rate of heat transfer through a material, a fundamental process across numerous industries. Accurate heat flow measurements are essential for assessing material performance and energy efficiency, particularly in the construction, insulation, and manufacturing sectors. The HFM 510A stands out for its versatility and precision, complying with standards like GB/T 10295, ASTM C518, and ISO 8301. This enables it to evaluate a wide array of low thermal conductivity materials including expanded and extruded polystyrene, PU rigid foam, mineral wool, and more innovative materials like aerogel and concrete, making it an invaluable tool for material researchers and engineers focused on thermal management.

Fundamentals of Heat Flow Measurement

Basics of Heat Transfer

Heat transfer is a fundamental process by which thermal energy moves from a higher to a lower temperature region. This process is crucial in various applications, from industrial manufacturing to residential heating. Understanding heat transfer mechanisms is essential for optimizing energy use and enhancing material performance.

Principles of Heat Flow Measurement

To effectively assess insulation materials, measuring thermal conductivity is crucial. Thermal conductivity indicates the quantity of heat that flows through a material per second per unit temperature difference across a defined thickness. This parameter helps in determining the thermal resistance (R-value), calculated as the material’s thickness divided by its thermal conductivity. Higher thickness results in greater resistance to heat transfer, enhancing insulation properties. The reciprocal of thermal resistance is the heat transfer coefficient (U-value), commonly used to describe structural materials’ thermal characteristics.

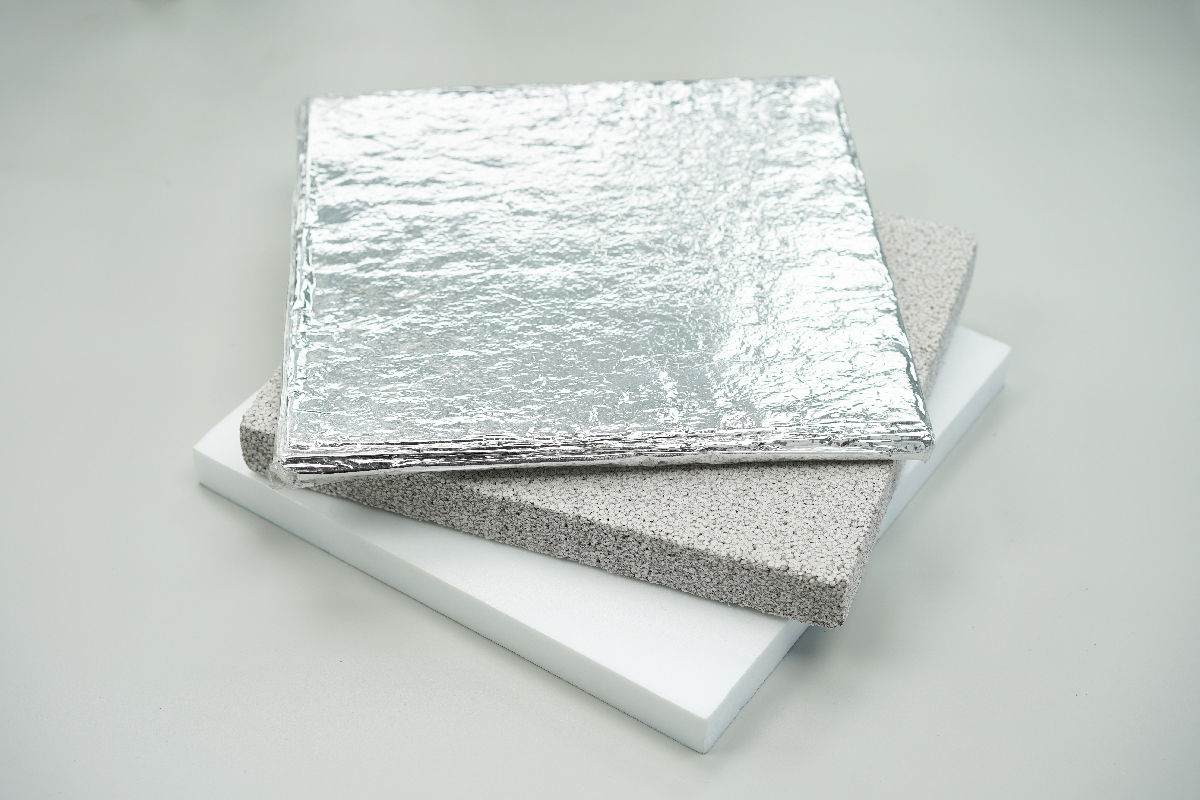

Precision heat flow meters, like the thermal conductivity meter, have revolutionized the measurement of thermal conductivity. This equipment is ideal for assessing thermal conductivity and resistance in materials with low thermal conductivity, such as fiberglass, building materials, and thermal insulation products. It’s ideal for a range of materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), PU rigid foam, mineral wool, and innovative materials like aerogel, thereby broadening its application in material development and evaluation.

Specifications of HFM 510A

Environmental and Temperature Controls

The HFM 510A operates effectively within an ambient temperature range of -5°C to 45°C and under humidity conditions of less than 95% RH. Its plate temperature range is broad, spanning from -30°C to 90°C, facilitated by an external refrigeration system. This extensive range allows for versatility in testing under various environmental conditions. Additionally, the device employs a Peltier system for precise temperature control of the plates, ensuring accurate and consistent measurements.

Sample and Measurement Specifications

The HFM 510A is designed to accommodate samples measuring 300mm in length and width, with a height of less than 100mm. It features a thermal resistance measurement range from 0.1 m²·K/W to 8 m²·K/W and a thermal conductivity range from 0.002 W/(m·K) to 1 W/(m·K), which is scalable up to 2 W/(m·K). The device ensures measurement accuracy within ±1% to 2% and a repeatability of 0.5%, highlighting its reliability and precision in thermal testing.

Advanced Features for Enhanced Usability

The HFM 510A supports more than ten set points, allowing for extensive customization of testing parameters to suit various research needs. It also features a variable load force of 21 kPa (1930N), adaptable for different material densities and compositions. The thickness range for samples extends from 0 to 100mm with a resolution of 0.02mm, providing fine granularity in measurement and enhancing the meter’s application in evaluating a wide range of material types.

Operating Principles of HFM 510A

How Heat Flow is Measured Using the Equipment

In the HFM 510A, the sample material is positioned between two plates, maintaining a specific temperature gradient. Heat flow through the material is quantified using two high-precision heat flow sensors located on each plate. Upon achieving an equilibrium state, where heat flow power remains constant, the thermal conductivity of the material is calculated employing the Fourier heat transfer equation. This method ensures that the intrinsic thermal properties of the material are accurately measured, providing critical data for industrial applications.

Factors Affecting Accuracy and Precision

The accuracy and precision of the HFM 510A are influenced by several factors including the stability of the temperature control, the uniformity of sample placement, and the calibration of the heat flow sensors. Ensuring consistent test conditions and proper handling of the samples is crucial to obtain reliable data. Additionally, the dual sensor design and independent temperature control for each plate enhance measurement precision by mitigating potential errors from uneven heat distribution.

Calibration Procedures

Calibration of the HFM 510A is vital for maintaining measurement accuracy. This process typically involves using reference materials with known thermal properties to set the baseline readings of the device. Regular calibration checks are recommended to ensure continued accuracy. Especially when the device is used extensively or under different environmental conditions. The system’s software facilitates easy calibration management, allowing routine accuracy checks and adjustments. To maintain the reliability and performance of the equipment in long-term use.

Applications of Precision Heat Flow Meter Equipment

Industrial Applications

Precision thermal flow meters like the HFM 510A are essential for industries that require rigorous testing of building materials and insulation materials. They help determine the thermal properties of various materials. Ensuring products such as insulating bricks, insulation panels and roofing materials meet required specifications and efficiency standards. This testing is vital for enhancing energy efficiency in buildings and complying with global environmental standards.

Research Applications

In academic and industrial research, the HFM 510A facilitates advanced studies on the thermal conductivity of new materials. Researchers utilize this equipment to explore innovative materials such as aerogels, which could revolutionize thermal insulation technology. Accurate thermal conductivity measurements are essential for developing materials that could significantly impact energy consumption patterns globally.

Quality Control and Product Development

For product development, the HFM 510A is indispensable in testing and refining prototypes of thermal insulation products. Quality control teams rely on precise heat flow measurements to ensure that products perform consistently and meet stringent industry standards before they reach the market. This rigorous testing process helps in mitigating risks associated with product failures and warranties.

In Closing

The HFM 510A stands as a high-quality instruments designed specifically for measuring thermal conductivity. The equipment is tailor-made to suit a variety of insulation materials and applications, from industrial quality control to cutting-edge research. Crucial for accurate assessment of thermal performance. The HFM 510A comes with features such as automated testing, comprehensive temperature control and advanced data management. Improves efficiency and accuracy across multiple industries. It complies with international standards and guarantees reliable results. making it an important asset in promoting innovation in insulation and building materials. Ultimately, the HFM 510A not only meets the current needs of various industries, but also lays the foundation for future developments in materials science and energy conservation. Highlighting its key role in technological development.