Heat Flow Meter Principle: A Key to Measuring Thermal Conductivity

Have you ever wondered how we measure the insulating properties of materials? From the foam in your home’s walls to the insulating materials used in aerospace, understanding heat flow is crucial for product performance. But how do scientists and engineers quantify how well materials resist heat transfer? The answer lies in the Heat Flow Meter, a high-precision instrument that plays a vital role in evaluating the thermal conductivity of various materials.

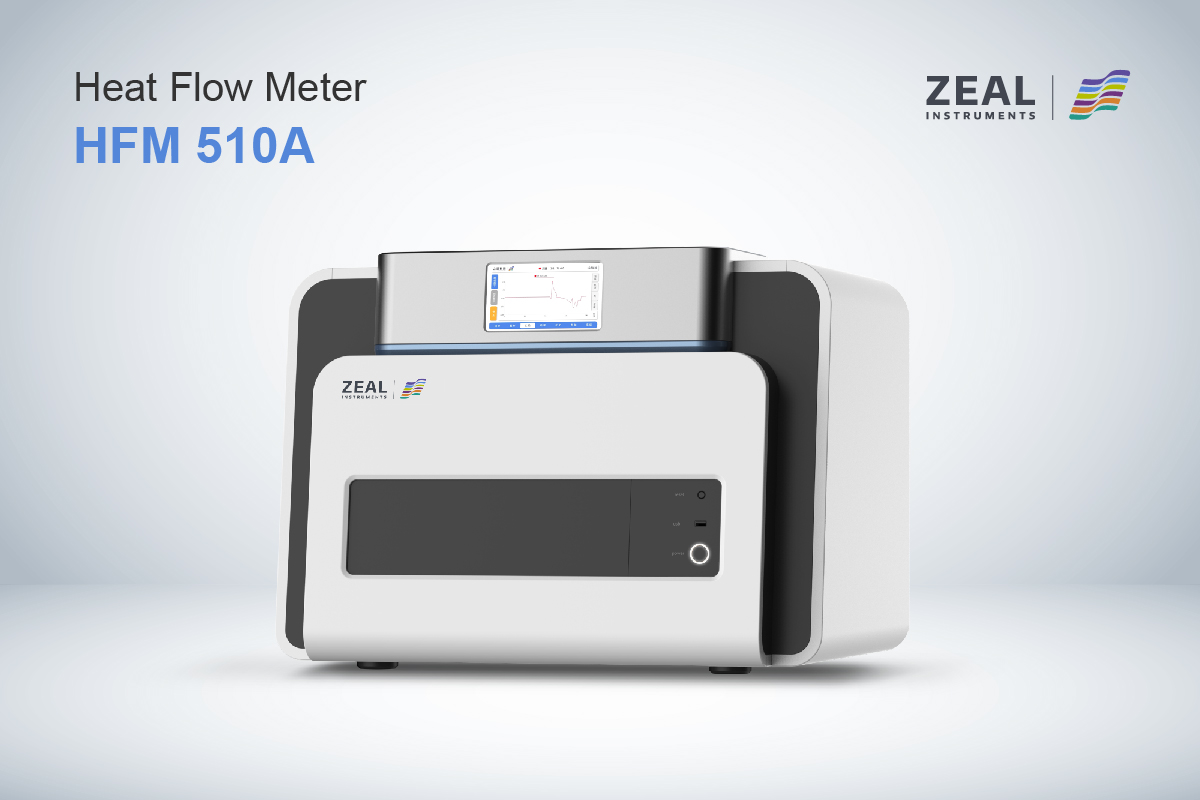

What is a Heat Flow Meter?

A Heat Flow Meter is a specialized instrument used for measuring the thermal conductivity and thermal resistance of materials, particularly insulating materials. It offers a fast, simple, and accurate means to assess materials with low thermal conductivity, such as foams, mineral wool, aerogels, and other insulation materials. Designed in accordance with international standards like ASTM C518, ISO 8301, and DIN EN 12667, the Heat Flow Meter is a critical tool in industries ranging from construction to aerospace, where understanding heat transfer is fundamental to ensuring energy efficiency, safety, and performance.

Heat Flow Meter Principle: How Does a Heat Flow Meter Work?

The Heat Flow Meter Principle is grounded in Fourier’s Law of Heat Conduction, which states that the rate of heat transfer through a material is directly proportional to the temperature gradient and the material’s thermal conductivity. This is where the Heat Flow Meter comes into play.

When a material is placed between two plates (heated and cold), the Heat Flow Meter measures the temperature difference between the two surfaces of the material. By calculating the amount of heat passing through the material, it determines the material’s thermal conductivity. Thermal conductivity (λ\lambdaλ) indicates the rate at which heat transfers through the material, while thermal resistance (RRR)—the inverse of thermal conductivity—quantifies the material’s ability to resist heat flow.

The Key Components: How the Measurement Works

The Heat Flow Meter operates by utilizing a controlled thermal environment. A sample is placed between two plates: one plate is heated, and the other is kept cooler. The device measures the temperature difference between the two plates as well as the amount of heat passing through the sample. This data allows the meter to compute the material’s thermal conductivity using Fourier’s Law.

In practical terms, the Heat Flow Meter’s sensors detect how much heat passes through a specific area of the material over a set period. These sensors are highly sensitive and can measure minute changes in temperature, ensuring the accuracy of the measurements. The result is a clear, quantifiable reading of thermal conductivity or resistance, which is then used to assess how well the material will perform in real-world applications.

Specifications of Heat Flow Meters

To fully appreciate the value of a Heat Flow Meter, it’s essential to understand its specifications. Here are some of the key parameters that define the capabilities of an Heat Flow Meter:

Operating Environment: Typically between -5°C to 45°C with a humidity level of less than 95%.

Plate Temperature Range: This varies from -30°C to 90°C, allowing it to test a wide range of materials in different thermal conditions.

Cooling System: External refrigeration ensures that the plates maintain stable temperatures during testing.

Control System: A Peltier system controls the temperature of the plates, providing high-precision temperature regulation.

Thermal Resistance Range: The Heat Flow Meter can measure materials with thermal resistances ranging from 0.1 m²·K/W to 8 m²·K/W.

Thermal Conductivity Range: It can measure thermal conductivities from 0.001 W/(m·K) to 1 W/(m·K), scalable up to 2 W/(m·K).

Accuracy and Repeatability: The device provides an accuracy of ±1% to 2%, with a repeatability of 0.5%, making it suitable for both research and industrial applications.

Thickness Range: The sample thickness can range from 0 to 100mm, with a resolution of 0.02mm, ensuring precise measurement of thin and thick materials alike.

Advanced Automation Features

One of the standout features of modern Heat Flow Meters is their high level of automation. These systems come with a host of integrated functionalities, such as automatic plate elevation, load force adjustment, and temperature control, all of which enhance ease of use and consistency during testing.

Additionally, many Heat Flow Meters have built-in sensors for automatic thickness measurement, ensuring that even uneven surfaces can be measured with high precision. This eliminates the need for manual calibration, allowing operators to focus on other aspects of their research or testing.

Modes of Operation

Heat Flow Meters offer flexibility by providing three distinct experimental modes: Standard, Fast, and Custom. This variety allows users to choose the mode that best suits their needs, whether they require standard precision measurements, rapid testing for preliminary results, or highly customizable setups for complex or specialized materials.

Advantages of Using Heat Flow Meters

The main advantage of Heat Flow Meters lies in their automation and adaptability. With automated functions such as sample loading, temperature control, and thickness measurement, the user experience is simplified and less prone to human error. The instruments can automatically adjust to sample irregularities, ensuring that even materials with non-flat surfaces can be accurately tested.

Moreover, the wide range of materials that the Heat Flow Meter can assess makes it invaluable in various industries. From construction insulation to aerospace applications, the Heat Flow Meter is versatile enough to measure the thermal properties of diverse materials such as expanded polystyrene, extruded polystyrene, polyurethane foam, mineral wool, expanded perlite, aerogels, and more.

Smart Data Management and Connectivity

Modern Heat Flow Meters come with integrated data management systems that allow users to track real-time measurement data and historical records. Many systems offer features such as user login for security, real-time data monitoring, historical data queries, and customizable report generation. These features make the instruments not only more efficient but also more user-friendly, as they facilitate the documentation and sharing of test results.

Furthermore, the devices often support a variety of peripheral connections, including the ability to interface with external keyboards, mice, and printers. This flexibility enhances the device’s usability in diverse laboratory and industrial environments.

Applications of Heat Flow Meters

Heat Flow Meters are indispensable tools in a wide array of industries. They are especially useful in the development and testing of insulating materials, including:

- Expanded Polystyrene (EPS)

- Extruded Polystyrene (XPS)

- Polyurethane Foam (PU)

- Mineral Wool

- Expanded Perlite

- Aerogels

- Natural Fibers

- Cork

- Wool

- Foam Glass

These materials are used in everything from construction and automotive manufacturing to energy storage and aerospace technology. By accurately measuring the thermal conductivity of these materials, Heat Flow Meters help ensure that products meet performance standards and are optimized for their intended applications.

Conclusion: Why Choose Hangzhou Zeal Instruments?

So do you know the Heat Flow Meter Principle now? The Heat Flow Meter provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd. stands out for its precision, automation, and ease of use. With a wide range of technical specifications and features, the device is well-suited for researchers and industries seeking to understand and improve the thermal properties of materials.

Whether you are conducting research in a laboratory or managing industrial testing processes, the Heat Flow Meter from Hangzhou Zeal Instruments offers a reliable solution that guarantees accurate and efficient results. Its advanced features, coupled with its compatibility with a variety of materials, make it an essential tool in thermal testing applications.

By offering high-precision, automated testing, and comprehensive data management, Hangzhou Zeal Instruments helps industries meet stringent performance standards while improving energy efficiency and product quality.