Heat Flow Meter for Thermal Conductivity Testing of Building Insulation Materials

The Heat Flow Meter (HFM) is the primary instrument used to measure the thermal conductivity of insulation materials in buildings. The testing principle involves placing the sample between two temperature-controlled plates, applying a constant temperature difference, and using a heat flow meter to measure the steady-state heat flow through the sample. The magnitude of heat flow Φ depends on factors such as the thermal conductivity λ of the sample, sample thickness ∆x, temperature difference ∆T between the cold and hot plates, and the heat transfer area A. According to Fourier’s formula, when thermal equilibrium is reached, the thermal conductivity λ can be calculated using the following formula:

Hangzhou Zeal Instruments Science & Technology Co., Ltd. presents the HFM 510A, a precise and efficient instrument for measuring thermal conductivity. It adheres to standards such as GB/T 10295-2008, DIN EN 12664, EN 12667, and JIS A1412. This article showcases the HFM 510A’s capabilities using three common insulation materials:

Sample Preparation

Extruded Polystyrene (XPS) Board

Made from polystyrene resin, this high-performance board features a uniform surface layer and closed-cell honeycomb structure, offering excellent thermal insulation and compressive strength for various building applications.

Vacuum Insulation Panel (VIP) Board

Comprising a core material with a vacuum-sealed surface layer, this panel minimizes heat transfer through air convection, providing low density and thermal conductivity, ideal for efficient insulation in walls, cold storage, and refrigerators.

Thermosetting Composite Polystyrene Foam Insulation (TEPS) Board

The Thermosetting Composite Polystyrene Foam Insulation (TEPS) board primarily uses silicate cement as the main cementitious material, supplemented with polystyrene foam particles, fibers, and additives. It boasts excellent fire resistance and insulation performance, making it widely used in building wall, roof, and floor insulation systems.Utilizing silicate cement and polystyrene foam particles, this board offers superior fire resistance and insulation, widely used in building insulation systems.

Test Conditions

| Item | Tmean Set Value | Conditions | Number of Trials |

| Thermal Conductivity | 25°C | Hot Plate Temperature: 35°C Cold Plate Temperature: 15°C |

3 |

Testing Steps

- Sample Preparation: Ensure samples are 300mm x 300mm x (5-100)mm, with surface slopes under 5° and theoretical thermal conductivity within (0.0021) W/(mK).

- Instrument Preparation: Prepare the instrument by turning it on, lifting the furnace door, and placing the sample on the tray. Ensure the sample is properly positioned, then close the tray and lower the furnace door.

- Parameter Setting: Set up the experiment, including names, sample data, and control options, then start.

- Record Results: Recording Results:** Post-experiment, record the thermal conductivity (λ) values.

Test Results

| Sample Name | Group | Thermal Conductivity λ (W/(m·K)) | Average Value W/(m·K) |

Repeatability |

| XPS board | 1 | 0.03989 | 0.03988 | 0.129% |

| 2 | 0.03992 | |||

| 3 | 0.03982 | |||

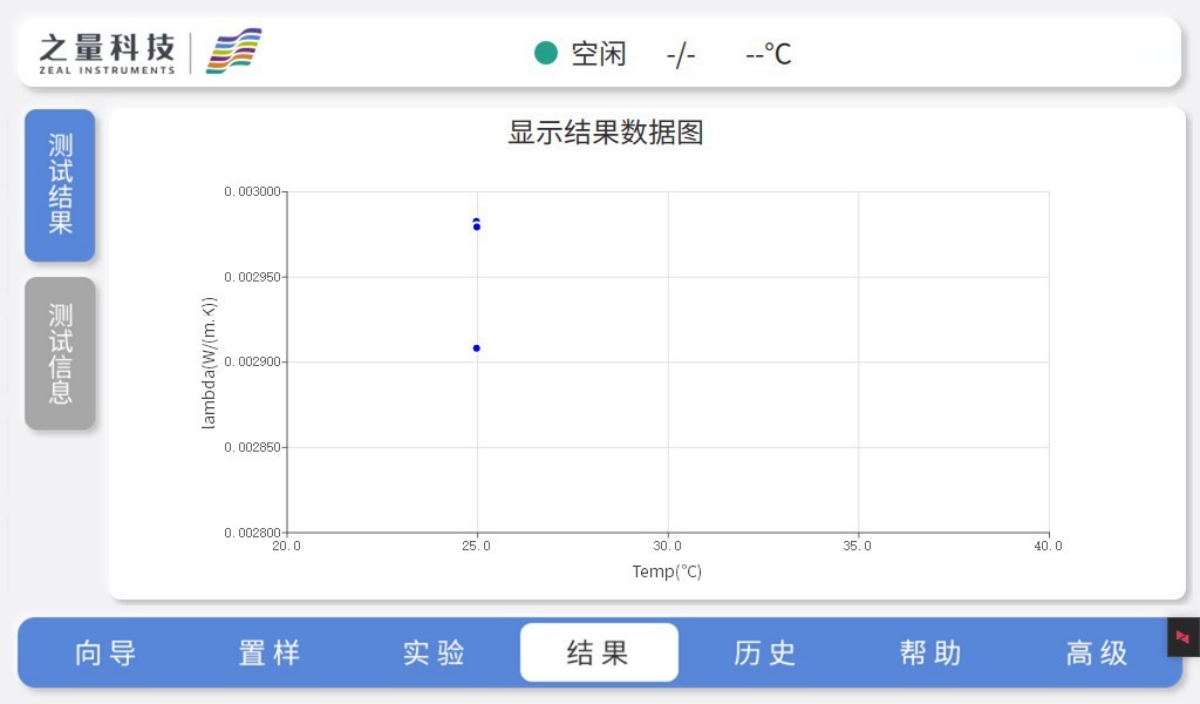

| VIP board | 1 | 0.00298 | 0.00296 | 1.367% |

| 2 | 0.00298 | |||

| 3 | 0.00291 | |||

| TEPS board | 1 | 0.05418 | 0.05429 | 0.212% |

| 2 | 0.05428 | |||

| 3 | 0.05441 |

Based on high-precision measurements, the Heat Flow Meter HFM 510A also supports graphical display of test results, aiding experimentalists in visually analyzing experimental outcomes to enhance efficiency. Using the VIP board as an example:

CONCLUSION

The HFM 510A demonstrates excellent measurement accuracy, especially for XPS and TEPS boards, with repeatability within 0.5%. The VIP board’s uneven surface, affecting thickness measurement (∆x), results in lower test repeatability. To ensure reliable results, sample surface smoothness should be improved during testing.

Test results indicate that the TEPS board has the highest thermal conductivity, followed by the XPS board. Notably, the VIP board shows the lowest thermal conductivity, highlighting its superior insulation capabilities.

The Heat Flow Meter HFM 510A demonstrated accurate measurements for all three sample types, with particularly high repeatability for the XPS and TEPS boards, within a 0.5% margin.

However, the uneven surface of the VIP board impacts the precise measurement of sample thickness (∆x), leading to reduced repeatability in thermal conductivity tests. To ensure reliable outcomes, it is recommended to enhance the sample surface smoothness during experimentation.