High-capacity 9- series Ternary Lithium-ion Battery Thermal Runaway Testing

Overview – Ternary Lithium-ion Battery

This article investigates the adiabatic heat dissipation behavior of a 130Ah 9-series ultra-high nickel NCM ternary lithium-ion battery using the BAC-420A Large Battery Adiabatic Calorimeter, filling the gap in the industry’s lack of thermal runaway data for large-capacity ultra-high nickel cores.

Introduction – Ternary Lithium-ion Battery

The 9-series ultra-high nickel ternary lithium-ion battery refers to a ternary lithium-ion battery with a positive electrode material elemental ratio of Ni:Co:Mn=9:0.5:0.5. As a solution that has maximized the potential of lithium battery positive electrode materials in the short term, the theoretical energy density of 9-series lithium batteries even exceeds 300Wh/kg. Due to the ultra-high energy density of 9-series lithium batteries, they have attracted close attention from OEMs committed to improving the range of new energy vehicles.

However, high energy density is accompanied by potential high risks. Therefore, obtaining thermal runaway characteristic parameters of 9-series batteries is particularly important. However, the thermal runaway process of 9-series lithium batteries is very intense, with a high probability of damaging instruments. Thus, experimental data on adiabatic thermal runaway of 9-series lithium batteries are extremely lacking, and battery thermal management design lacks experimental data support.

This article conducted adiabatic thermal runaway tests on 130Ah 9-series NCM ultra-high nickel lithium-ion batteries using the BAC-420A Large Battery Adiabatic Calorimeter to obtain relevant thermodynamic characteristic parameters of the thermal runaway process of this battery. The related results are helpful for researchers to clarify the thermal runaway hazards of 9-series batteries and optimize battery safety design.

Experimental Section

1. Sample preparation

1.1 Experimental sample: 130Ah 9-series NCM lithium-ion battery 1, 260mm100mm*25mm, 100% SOC.

2. Experimental conditions

2.1 Experimental instrument: BAC-420AE Large Battery Adiabatic Calorimeter;

2.2 Operating mode: HWS mode, temperature difference baseline mode;

2.3 Standard aluminum block: 6061 aluminum alloy material.

Figure 1: Large Battery Adiabatic Calorimeter(BAC-420A)

3. Experimental Procedure

3.1 Temperature Difference Baseline Calibration: Conduct temperature difference baseline mode experiments using standard aluminum blocks that match the size and shape of the battery to calibrate the thermocouples and instruments.

3.2 Standard Aluminum Block HWS Experiment: Perform HWS mode experiments using standard aluminum blocks to verify the effectiveness of temperature difference baseline calibration and the adiabatic performance of the instruments during the experimental process.

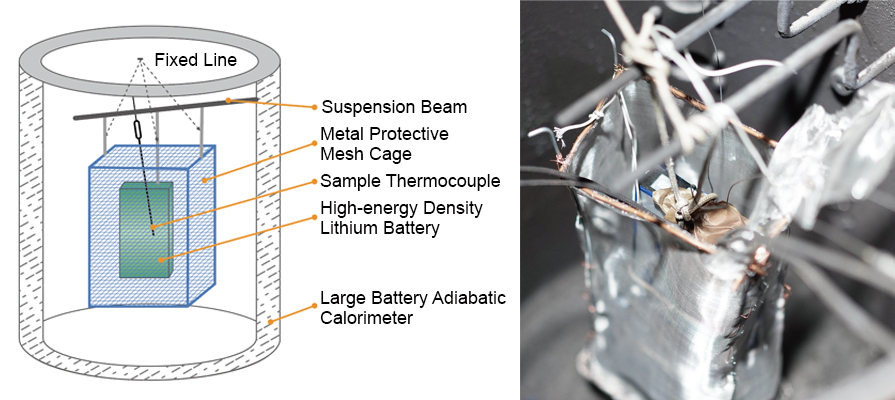

3.3 Battery HWS Experiment: To prevent thermal runaway damage to the furnace chamber by 9-series batteries, a metal mesh protective cover as shown in Figure 2 is added externally to the battery, and adiabatic thermal runaway experiments are conducted in HWS mode.

Figure 2: Schematic diagram and actual photo of the experimental setup for 9-series battery experiments

3.4 Standard Aluminum Block HWS Experiment: After the battery HWS experiment, conduct a new HWS validation experiment using standard aluminum blocks to verify whether the instrument functions normally after thermal runaway and the extent of sensor drift.

Experimental Results

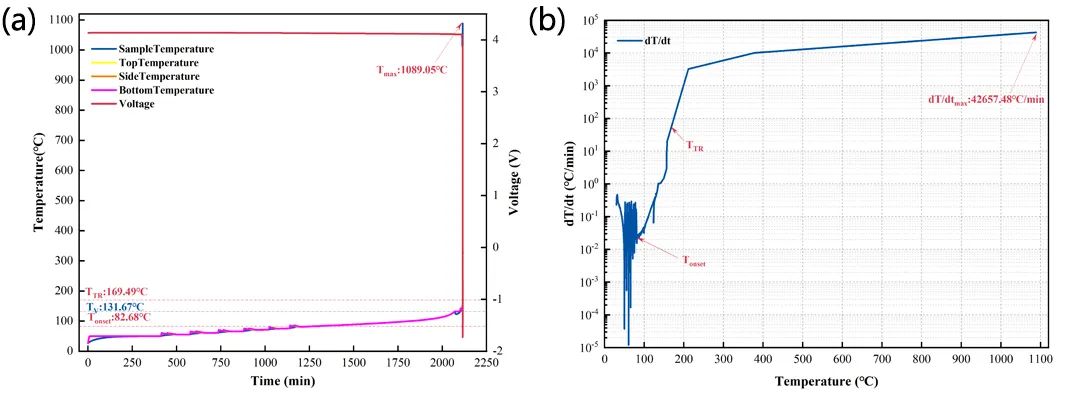

Figure 3: (a) Temperature-time curve and (b) temperature rise rate-temperature curve of battery adiabatic thermal runaway

As shown in Figure 3(a), the self-heating temperature rise rate of the battery reached the Tonset detection threshold of 0.02°C/min at 82.68°C. At 131.67°C, the venting temperature Tv was reached, and the pressure relief valve opened. Subsequently, at 169.49°C, the thermal runaway initiation temperature TTR (60°C/min) was reached, and the battery experienced thermal runaway. Within a few seconds, the temperature rapidly increased to approximately 1090°C, with a maximum temperature rise rate (dT/dt)max exceeding 40000°C/min.

Additionally, as observed from the monitoring screens inside and outside the explosion-proof box shown in Figure 4, it can be noted that the thermal runaway process of the battery was extremely intense. Strong jet flames and a large amount of smoke were ejected within a very short period. Simultaneously, the high-temperature and high-pressure airflow generated instantaneously exerted a certain impact on the laboratory walls.

|

|

| Figure 4: (a) Video inside the explosion-proof box and (b) Video outside the explosion-proof box | |

Figure 5: Photo of battery debris

By observing the battery debris, it can be observed that the venting valve position is completely shattered. Meanwhile, the battery debris consists mainly of the external aluminum shell, with almost all internal battery materials ejected from the venting port. The mass loss rate of the battery after thermal runaway reached 85.97%, indicating the severity of thermal runaway of the 9-series cell.

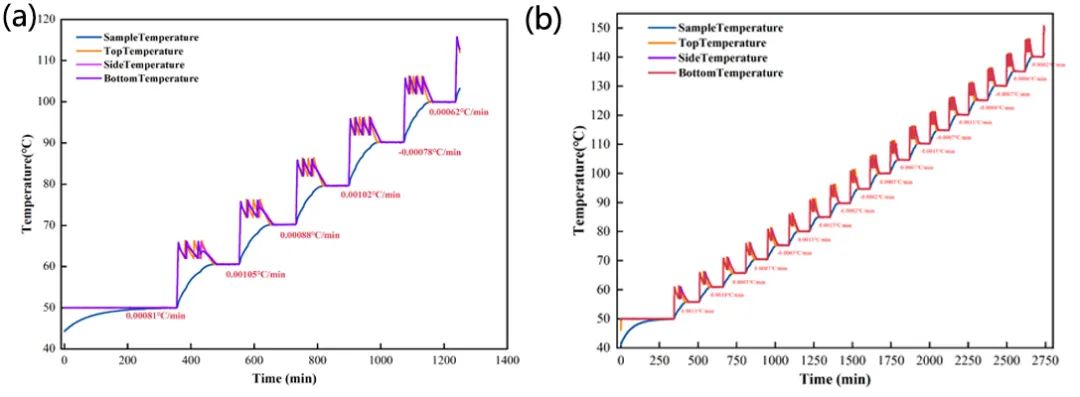

Figure 6: (a) Temperature rise rate curves of aluminum blocks in HWS mode before battery thermal runaway and (b) after battery thermal runaway

Prior to battery testing, the insulation performance of the instrument was verified through HWS experiments with standard aluminum blocks, as shown in Figure 6(a), where the temperature rise rates of each temperature step of the aluminum blocks were all less than ±0.002°C/min. After the battery test, in order to confirm whether the instrument could still function normally after enduring the severe explosion of the 9-series lithium battery, a new set of HWS experiments with standard aluminum blocks was conducted.

Figure 6(b) indicates that the instrument operated well during the experiment, with temperature rise rates for each step of the aluminum blocks remaining below ±0.002°C/min. The insulation performance remained excellent, demonstrating that the instrument functioned properly and that the sensors did not exhibit significant drift.

Understanding Large Battery Adiabatic Calorimeter (BAC-420A) by ZEAL INSTRUMENTS

- Simulating Ideal Conditions:The BAC-420A creates an ideal adiabatic environment, allowing precise measurement of critical parameters such as thermal runaway onset temperature, maximum rate of temperature rise, and adiabatic temperature rise. This enables researchers to understand the intricate mechanisms behind battery thermal runaway and analyze the process of heat diffusion and fire spread with high accuracy.

- Comprehensive Data Acquisition: With simultaneous monitoring of battery voltage, current, temperature, and pressure, the BAC-420A facilitates in-depth thermal runaway analysis. This comprehensive data acquisition capability ensures researchers have access to a wealth of information to enhance battery safety.

- Integrated Charging and Discharging Module:The device comes equipped with an integrated charging and discharging module, enabling seamless mode switching, customizable charging settings, current adjustments, and real-time battery capacity calculations. This functionality empowers researchers to tailor experiments according to their specific requirements and obtain precise results.

- Enhanced Specific Heat Testing:Through constant power and constant rate specific heat test modes, the BAC-420A enhances the accuracy of battery specific heat measurements. This unique testing process ensures researchers can accurately determine the specific heat capacity of batteries, crucial for understanding their thermal behavior.

Conclusion

The severity of adiabatic thermal runaway in large-capacity 9-series ultra-high nickel NCM lithium batteries is high. Laboratories should have sufficient venting and explosion relief areas (recommended to be above 50 square meters), and laboratory walls should be reinforced.

The BAC-420A Large Battery Adiabatic Calorimeter exhibits excellent pressure resistance and explosion resistance, capable of withstanding the thermal runaway explosion impact of large-capacity ultra-high energy density cells.