How Does Differential Scanning Calorimetry Work?

Differential Scanning Calorimetry (DSC) is a powerful analytical technique that measures the heat flow into or out of a sample as it undergoes heating or cooling. Widely used in fields such as materials science, pharmaceuticals, and research, DSC provides essential insights into the thermal properties of materials. This technique enables scientists to assess how materials respond to temperature fluctuations, offering critical information on their stability, composition, and behavior. Zeal Instruments has been at the forefront of delivering cutting-edge testing technologies and instruments since its inception. With a strong focus on continuous innovation and excellence, we are committed to advancing research in emerging fields, particularly in new materials and energy.

What is Differential Scanning Calorimetry (DSC)?

Definition and General Concept of DSC

Differential Scanning Calorimetry (DSC) is a technique used to measure the heat flow in and out of a sample as it is heated or cooled. The primary purpose of DSC is to study the thermal properties of materials. It helps to identify important characteristics, such as melting points, glass transitions, and heat capacity. By comparing the heat flow between a sample and a reference, DSC provides valuable data about how the material responds to changes in temperature.

History and Development of DSC as an Analytical Tool

In 1955, a significant improvement was made to Differential Thermal Analysis (DTA) equipment. Boersma enhanced the DTA setup, creating a stable linear relationship between the heat flow and the temperature difference of the sample. This breakthrough allowed for the quantitative measurement of heat flow and marked the creation of the “heat flow type” DSC.

Compared to the “power compensation type” DSC, the “heat flow type” DSC has several benefits. It offers a stable baseline, high sensitivity, and lower operational and maintenance costs. Over time, DSC technology continued to evolve. The methods for measuring heat flow were refined, and the accuracy of instruments improved. These developments played a key role in advancing thermal analysis science.

Common Materials Analyzed by DSC

DSC is used to analyze a wide range of materials, including polymers, metals, and pharmaceuticals. For example, in polymer studies, DSC helps to determine the melting points and crystallization behavior of plastics. In the pharmaceutical industry, DSC can identify the stability of active ingredients. It is also widely used in metals and alloys to study phase transitions and other thermal properties.

How Does DSC Work?

Explanation of the Basic Mechanism

The basic mechanism of DSC involves measuring the heat flow between a sample and a reference. Both the sample and the reference are placed in a closed cylindrical furnace. Heat is applied to both using a sensor. This sensor is connected to a heating block that transfers heat to the sample. A heat flow sensor made of a nickel-chromium alloy is used to measure the temperature difference. This system ensures precise monitoring of temperature changes during the analysis.

Temperature Control and Heat Difference Measurement

Temperature control in DSC is critical for accurate measurements. The temperature of both the sample and the reference is increased or decreased at a constant rate. The heat difference between the sample and the reference is continuously monitored. As the temperature changes, any variation in heat flow between the sample and the reference is detected. This data is used to calculate the thermal properties of the material.

Types of Thermal Transitions DSC Detects

DSC can detect various thermal transitions. Common examples include melting points, glass transitions, and crystallization points. For instance, when a polymer is heated, DSC can determine its melting point by measuring the point at which the material transitions from solid to liquid. Similarly, the glass transition temperature, which marks the change from a hard, glassy material to a softer, rubbery state, can also be observed. These transitions provide crucial information about the material’s thermal behavior and stability.

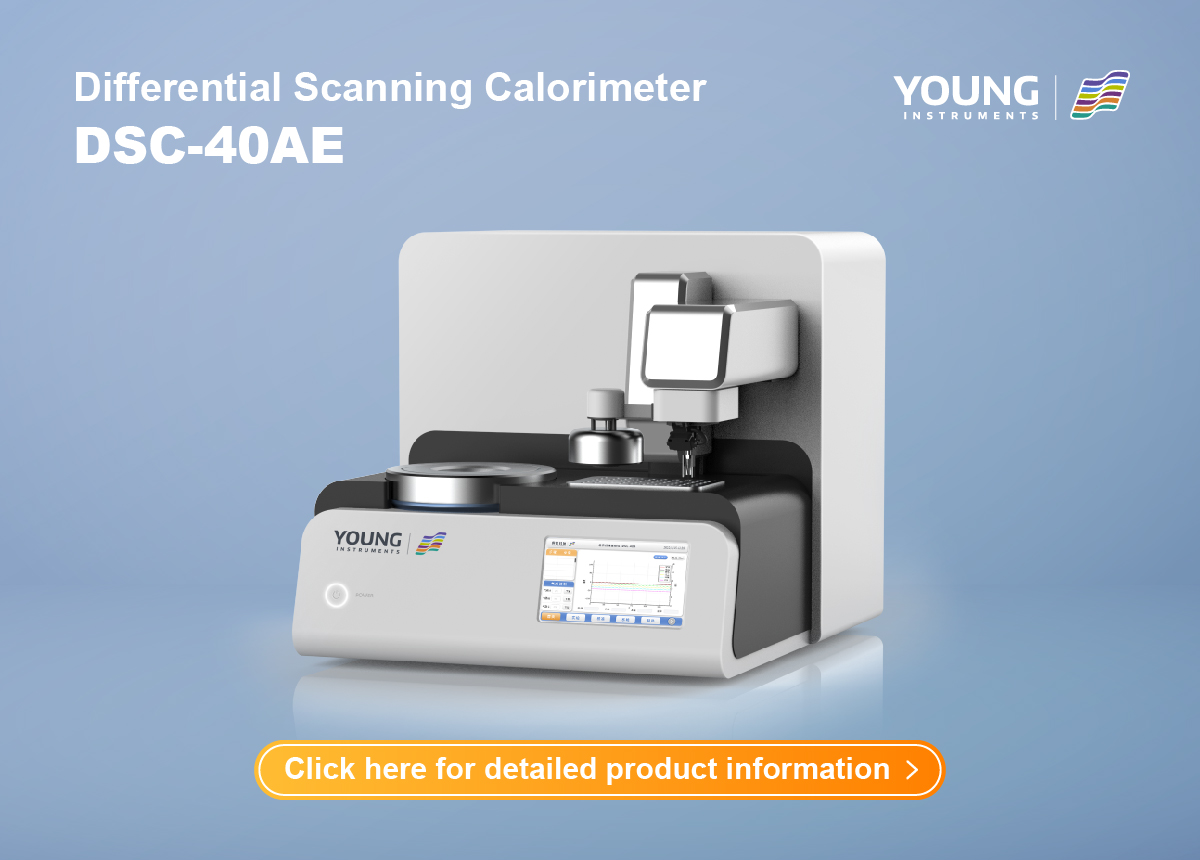

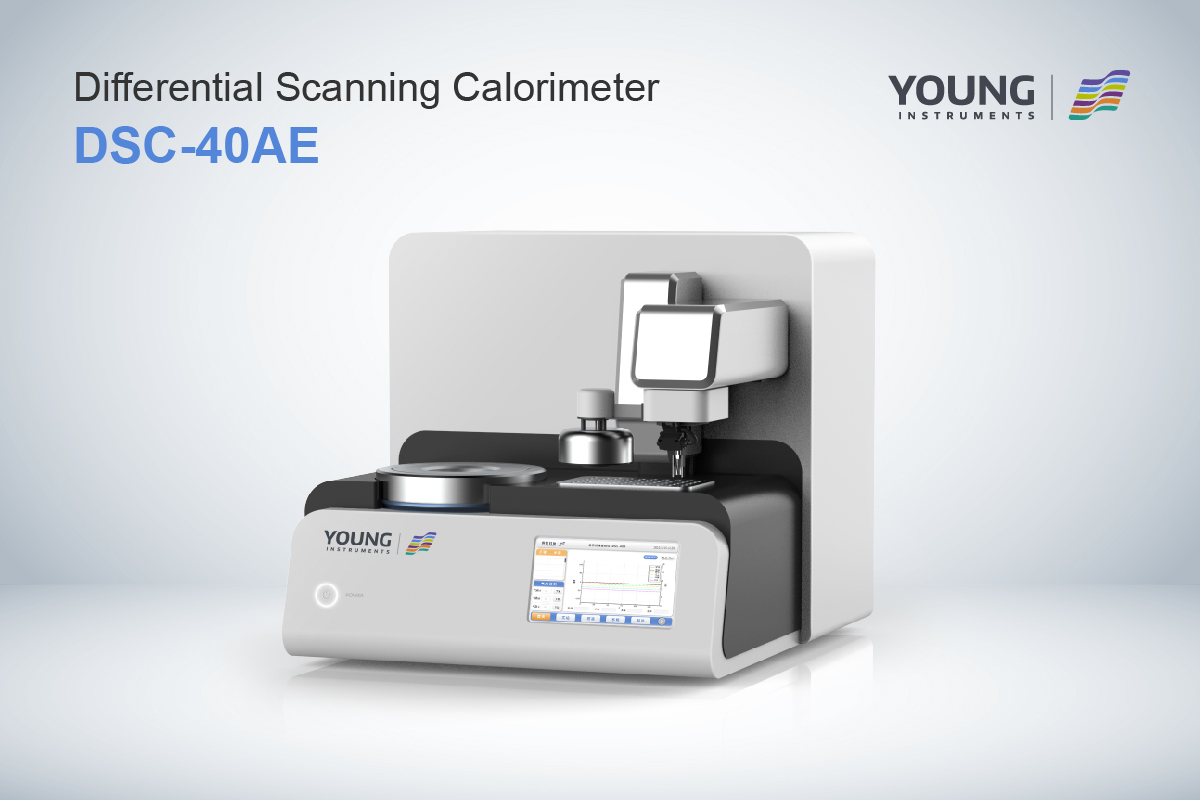

Advantages of DSC – DSC-40AE

Enhanced Resolution and Sensitivity

The DSC-40AE considers and calibrates differences in the physical properties of the heat flow sensor’s reference and sample ends. It also accounts for variations in the heating rate. This results in superior resolution and sensitivity compared to traditional DSC models.

Advanced Heat Flow Technology

The DSC-40AE uses tower-type heat flow technology. This enhances the resolution and sensitivity of the instrument. Additionally, the silver furnace body ensures higher heat transfer efficiency. This reduces cross-interference between the reference and sample.

Specialized Algorithms and Precise Measurement

The DSC-40AE employs specialized algorithms. These algorithms precisely modulate the temperature and heat flow signals. As a result, it enables accurate measurements of specific heat capacity and exothermic reactions. The device also features both ramp and isothermal temperature control modes.

Improved Data Acquisition and Durability

The DSC-40AE has a data acquisition rate of 50Hz. This significantly improves both sensitivity and resolution. The nickel-chromium substrate enhances high-temperature oxidation resistance, sensitivity, and dynamic response. The optimized structural design ensures reliable baseline stability and improves the signal-to-noise ratio. The instrument is also equipped with a high-definition touchscreen, making it easy to operate.

Applications of DSC

Overview of DSC as a Research Tool

DSC is a powerful tool for studying the thermal properties and thermal reactions of materials. It is easy to operate. The technique is widely used and provides clear physical data. With proper calibration and sample preparation, DSC can deliver accurate results.

Testing Thermal Properties and Transitions

DSC can test several important thermal parameters. These include specific heat capacity and thermal transition temperatures. For example, it can measure the glass transition temperature and the melting point of a material. DSC also tests transition enthalpy, which is the amount of heat absorbed or released during a phase change.

Wide Range of Applications

DSC is used in many fields. In pharmaceuticals, it helps to determine the stability of drugs. In the polymer industry, DSC is used to study the thermal properties of plastics and rubber. For electronic materials, DSC can measure heat resistance, which is important for product durability. The technique is also applied to battery materials to analyze their performance and thermal stability.

Importance of Proper Setup and Control

For accurate results, DSC requires proper setup. This includes instrument calibration and careful sample preparation. Temperature program control is also important, along with maintaining a controlled atmosphere. With these techniques, DSC can provide reliable data for various applications.

Closing Words

In conclusion, Differential Scanning Calorimetry (DSC) is an indispensable tool for analyzing the thermal properties of materials. Known for its high sensitivity and resolution, DSC is suitable for a wide array of applications. It measures crucial thermal parameters such as specific heat capacity, glass transition temperature, and melting points. This technique is widely used across industries like pharmaceuticals, polymers, electronics, and battery materials. The DSC-40AE, in particular, stands out with its advanced features, including precise temperature control, enhanced sensitivity, and an intuitive touchscreen interface for seamless operation. With proper calibration and setup, DSC ensures reliable and accurate data, making it essential for material research and development.