What is ISO 8301 and Its Impact on Thermal Conductivity Testing

In sectors ranging from construction to high-tech manufacturing, the accurate measurement of thermal conductivity is a fundamental requirement. Have you ever wondered how specialists evaluate how well materials resist heat flow? This critical property, especially in the context of insulation materials, directly impacts the performance and safety of products. ISO 8301, a globally recognized standard for thermal conductivity testing, ensures that this property is measured with precision, significantly affecting product quality, safety, and overall performance. This post explores the importance of ISO 8301, its role in material testing, and how cutting-edge tools like the Heat Flow Meter (HFM 510A) are transforming the landscape of thermal conductivity assessment.

Why ISO 8301 Matters in Material Testing

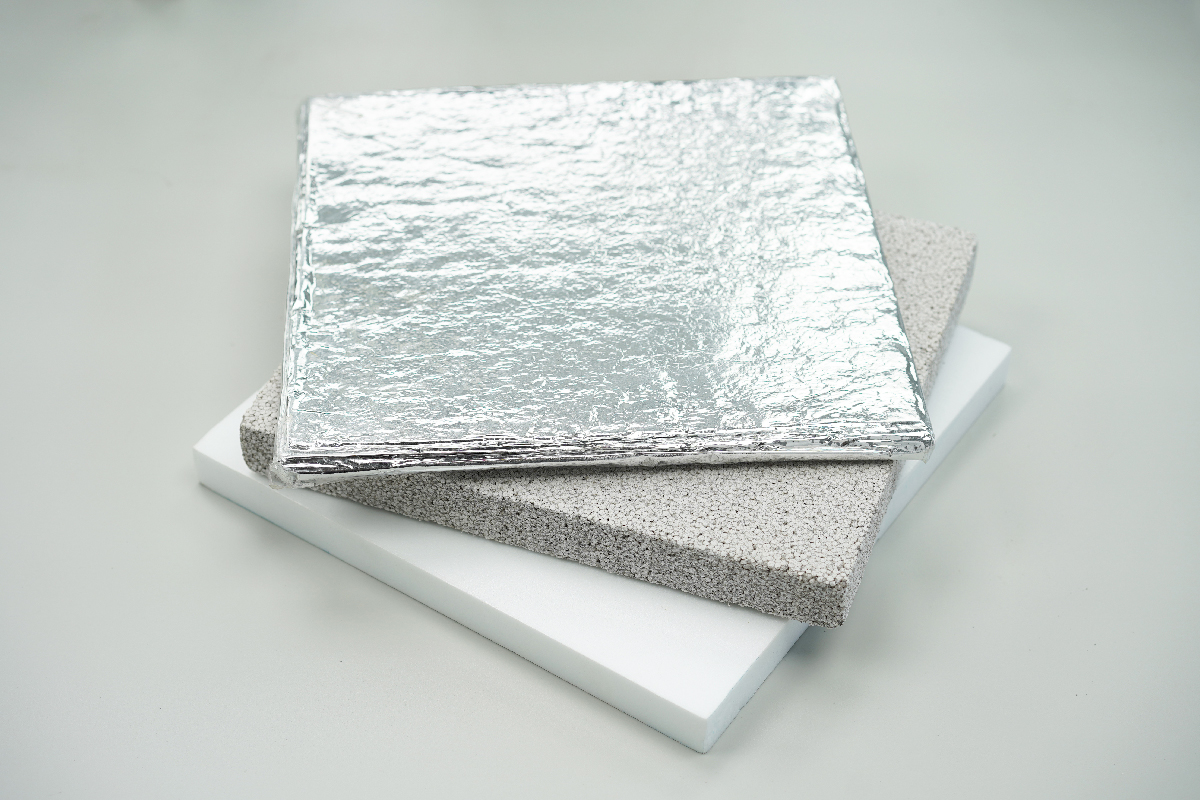

ISO 8301 serves as an essential benchmark in the testing of materials used in insulation, energy systems, and other applications where heat resistance is critical. Whether the material is expanded polystyrene, aerogel, or mineral wool, adherence to ISO 8301 allows manufacturers to consistently measure and report thermal conductivity in a standardized way, recognized across the industry. The reproducibility of these results ensures that they remain reliable, which is vital for quality control, regulatory compliance, and making informed decisions when comparing different products.

Following the guidelines set forth by ISO 8301 enables manufacturers to verify that their materials meet the required performance levels for insulation and other thermal applications. This consistency and precision are especially crucial in industries like construction, energy, and manufacturing, where thermal efficiency and performance directly impact cost-effectiveness and operational success. Ultimately, ISO 8301 guarantees that materials, once tested, will perform as required in the most demanding conditions.

The HFM 510A Heat Flow Meter: A Revolution in Thermal Conductivity Testing

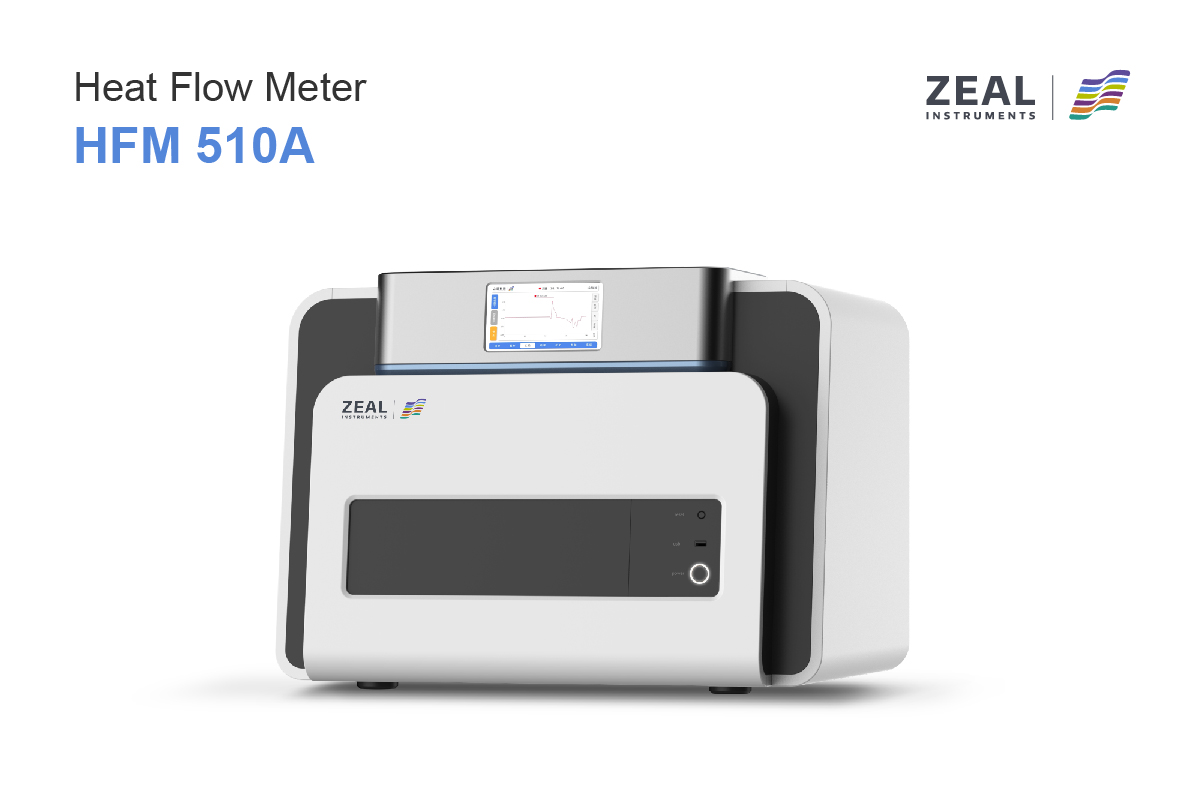

For testing to be conducted in compliance with ISO 8301, advanced instrumentation is indispensable. One of the most cutting-edge tools for this task is the Heat Flow Meter (HFM) 510A, which automates the process of thermal conductivity measurement with high precision. Designed to deliver results that align with global industry standards, the HFM 510A plays a crucial role in improving the efficiency and reliability of thermal conductivity testing.

The HFM 510A is engineered to test a wide array of low thermal conductivity materials, including:

- Expanded Polystyrene (EPS)

- Extruded Polystyrene (XPS)

- Polyurethane (PU) Rigid Foam

- Mineral Wool

- Expanded Perlite

- Foam Glass

- Natural Fiber Materials

- Cork

- Wool

- Aerogel

- Concrete

- Gypsum

Compliant with international standards like GB/T 10295, ASTM C518, and ISO 8301, the HFM 510A provides rapid, highly accurate results, making it an indispensable tool for manufacturers, researchers, and material scientists.

Key Features of the HFM 510A Heat Flow Meter

1. Fully Automated and Efficient Testing Process

The HFM 510A is equipped with numerous automated features that streamline the testing process. These include automatic lifting and lowering of the heating plate, automatic load force measurement, automatic thickness measurement, and precise temperature control. By minimizing the need for manual intervention, these automated functions reduce the chances of human error, boost testing throughput, and speed up the process. This is particularly beneficial for laboratories and manufacturers that require quick results in high-volume testing scenarios.

2. Dual Heat Flow Sensors for Enhanced Accuracy

The HFM 510A incorporates dual heat flow sensors, which significantly increase the accuracy of thermal conductivity measurements. By using two sensors, the device ensures that even the smallest variations in thermal resistance are detected, improving the precision of the data. This dual-sensor system is particularly useful for identifying inconsistencies in materials, such as variations in thickness or composition, which might otherwise go unnoticed.

3. Independent Temperature Control for Precision

A standout feature of the HFM 510A is its ability to independently control the temperatures of both the upper and lower plates during testing. This precise control allows for thermal conductivity tests to be conducted under highly controlled conditions, ensuring that the temperature settings are in line with the parameters outlined in ISO 8301. The ability to adjust temperatures independently is especially important when testing materials under varying conditions, providing more accurate measurements of their thermal behavior.

4. Adaptability to Irregular Surfaces

Another important capability of the HFM 510A is its ability to handle uneven sample surfaces. This is particularly relevant when testing materials like foam or composite substances, which often have non-uniform surfaces. The device can accommodate a wide range of sample shapes and sizes, ensuring accurate measurements even when the surfaces are not perfectly flat or smooth. This feature eliminates the need for extensive sample preparation, saving both time and resources.

5. Comprehensive Software and Data Management

The HFM 510A is paired with sophisticated software that enhances testing flexibility and efficiency. The software supports a variety of measurement accessories and modes, allowing users to adapt the system to specific testing needs. Offline operation is supported, providing added flexibility in test management. The software also features automated data collection, real-time monitoring, and the generation of test reports for seamless record-keeping.

In addition, the software supports peripheral devices such as mice, keyboards, and printers, providing excellent expandability. Features like user login capabilities, historical data queries, and customizable data storage/export options make the HFM 510A ideal for laboratories that require detailed records for regulatory compliance and quality control.

HFM 510A Specifications

Operating Temperature Range: -5°C to 45°C, <95% RH

Plate Temperature Range: -30°C to 90°C

Thermal Conductivity Range: 0.001 W/(m·K) to 1 W/(m·K), scalable up to 2 W/(m·K)

Thermal Resistance Range: 0.1 m²·K/W to 8 m²·K/W

Thickness Measurement Range: 0 to 100 mm

Accuracy: ±1% to 2%

Repeatability: 0.5%

Load Force: 21 kPa (1930 N)

Sample Size: 300mm x 300mm, Height ≤100mm

Cooling System: External refrigeration with Peltier plate temperature control

Dimensions: Compact design with a high-definition touchscreen interface

Applications Across Industries

The synergy between ISO 8301 and the advanced functionality of the HFM 510A opens up numerous possibilities for various industries where accurate thermal conductivity measurements are essential:

Construction and Building Materials: Insulation materials such as mineral wool and expanded polystyrene must undergo precise testing to meet stringent energy efficiency standards.

Energy Sector: In energy-efficient systems, including passive solar panels and HVAC components, accurate thermal testing is critical to maximize efficiency and performance.

Automotive and Aerospace: Lightweight and thermally efficient materials play a key role in reducing fuel consumption and improving comfort in automotive and aerospace designs.

Research and Development: R&D teams rely on the HFM 510A to test innovative materials, such as aerogels, that promise to transform industries through advanced insulation properties.

Conclusion

ISO 8301 provides a critical framework for thermal conductivity testing, ensuring consistency and precision across industries. The HFM 510A, adhering to ISO 8301 standards, delivers precise thermal conductivity measurements for solid and powdered insulation materials, meeting diverse R&D testing requirements. By automating and optimizing the testing process, the HFM 510A empowers manufacturers, laboratories, and researchers with unmatched accuracy and efficiency. Whether it’s evaluating building insulation materials, energy-saving systems. Whether you are developing innovative materials or developing innovative materials, the HFM 510A is your first choice for reliable thermal conductivity analysis. For those seeking excellence in thermal management and product quality. Investing in the HFM 510A is an important step towards achieving the highest performance standards.

For further information or to request a demo, visit Hangzhou Zeal Instruments Science & Technology Co., Ltd. today.