Assessing Lithium Battery Explosion Test: Introducing the Large Battery Adiabatic Calorimeter (BAC-420AE)

Lithium Battery Explosion Test With the increasing prevalence of lithium batteries across diverse applications, prioritizing their safety is essential. Given the risk of explosion associated with improperly managed lithium batteries, it underscores the importance of conducting secure, precise, and dependable adiabatic thermal runaway tests in laboratory settings.

These tests are crucial for accurately evaluating the safety margins and potential failure hazards of battery cells. The Large Battery Adiabatic Calorimeter (BAC-420AE) is a critical tool designed to address these safety concerns. This advanced instrument integrates comprehensive testing methodologies, including thermal, electrical, and mechanical abuse tests, enhanced by visible and infrared imaging, gas analysis, and specific heat testing.

With the BAC-420AE, crucial parameters like battery-specific heat capacity, heat generation rates during charge/discharge cycles, thermal runaway initiation temperatures, maximum thermal runaway rates, and adiabatic temperature rise can be accurately determined, providing a thorough assessment of relevant thermodynamic characteristic parameters of the battery thermal runaway process.

Background Lithium Battery Explosion Test

Rising Demand for Advanced Energy Storage Solutions

As electric vehicles (EVs) gain traction and renewable energy sources become increasingly integrated into the power grid, there is a surging need for batteries capable of storing large amounts of energy efficiently. This demand is fueled by the desire to reduce reliance on fossil fuels and mitigate environmental impact. High-capacity, high-energy-density batteries are essential for meeting the power requirements of EVs and ensuring the stability and reliability of renewable energy systems.

Challenges in Battery Safety and Performance

Despite the promising prospects of advanced battery technologies, concerns regarding their safety and performance persist. Lithium batteries, in particular, are susceptible to thermal runaway and degradation under extreme conditions, posing significant safety risks. Moreover, the energy density and cycle life of conventional batteries fall short of meeting the evolving demands of modern applications. Addressing these challenges requires innovative approaches to battery design, testing, and characterization. Current methods, such as battery accelerated rate calorimetry (ARC), while valuable, are inadequate for fully assessing the safety and development requirements of emerging lithium battery technologies. Thus, there is a pressing need for enhanced testing protocols and technologies to ensure the safe and reliable operation of next-generation energy storage systems.

Development of the BAC-420AE

In response to these challenges, the Large Battery Adiabatic Calorimeter (BAC-420AE) was developed. It refines testing by evaluating critical parameters like Thermal Runaway Onset Temperature, Maximum Rate of Temperature Rise, Adiabatic Temperature Rise, and Specific Heat Capacity, alongside measuring Heat Generation during Charging/Discharging. This allows for a more comprehensive understanding of the conditions that lead to battery failures.

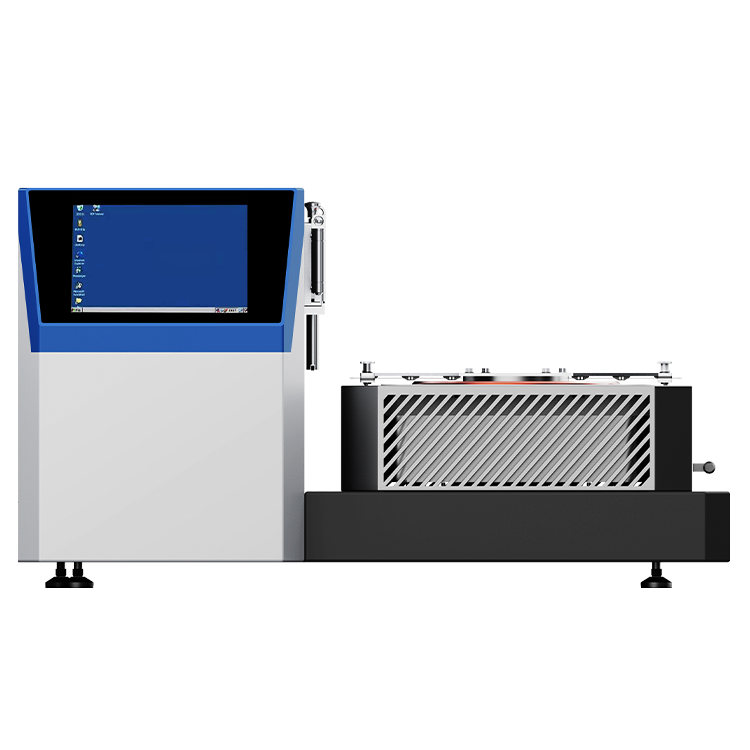

Design and Components of the BAC-420AE

The Lithium Battery Explosion Test BAC-420AE is meticulously designed to enhance the reliability and accuracy of lithium battery safety tests.

Overview of the Calorimeter Design

The calorimeter simulates an ideal adiabatic environment, crucial for directly measuring precise thermal behavior parameters. This setup is crucial for accurately determining the onset and progression of thermal runaway in batteries.

Key Components and Their Functions

The BAC-420AE is equipped with an integrated system that measures battery voltage, current, temperature, and pressure during thermal runaway scenarios. Additionally, it features a versatile battery charging and discharging module that supports mode switching and real-time battery capacity calculations.

Advantages of the BAC-420AE Over Traditional Methods

Unlike traditional methods, the BAC-420AE provides a more detailed and realistic assessment of battery behavior under various stress conditions. It adheres to global standards, including GB/T 36276-2023, UL 9540A, and others, ensuring compliance and relevance in diverse testing environments. This comprehensive approach allows for better prediction and prevention of battery failures in new energy vehicles. The overall structure of the instrument is divided into three parts: the adiabatic chamber, explosion-proof box, and electronic control system. The pressure relief series has excellent multiple safety protection capabilities. It utilizes a spring lock design, where the furnace cover can quickly pop up for rapid pressure relief when the internal pressure is too high. Additionally, burst discs are installed inside the chamber for protection. The explosion-proof box employs mechanical safety interlock devices, with a steel plate thickness of 3.5mm, and is equipped with a high-flow exhaust system to ensure experimental safety.

Testing Procedure

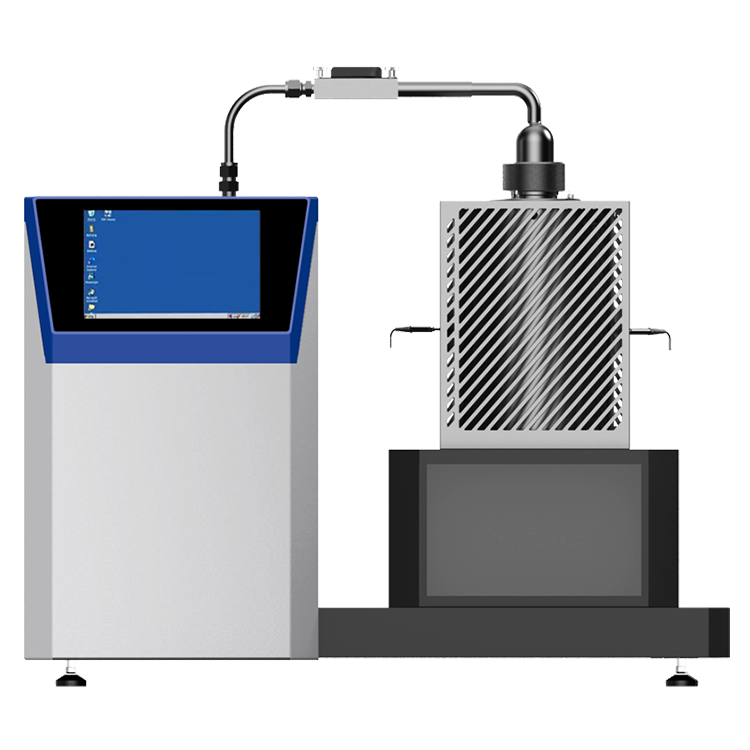

The Large Battery Adiabatic Calorimeter (BAC-420AE) exemplifies cutting-edge technology with its meticulous design that includes a pressure relief-type structure, enhancing both operational convenience and safety. This section details the comprehensive testing procedure enabled by the BAC-420AE, ensuring a thorough assessment of lithium battery safety.

Preparing the Lithium Battery Sample

Sample preparation is a critical initial step. Following specifications, surface treatment of the battery is conducted, followed by activation and control of the state of charge (SOC), with basic data such as battery mass and voltage being recorded.

Loading the Battery into the Calorimeter

The BAC-420AE’s design includes a cavity within a cavity structure for double protection and rapid pressure relief, significantly enhancing safety. The battery is carefully placed into the calorimeter, ensuring correct alignment with sensors and connections for accurate data collection.

Initiating the Test

Testing begins with the calorimeter tightly sealed, utilizing an anti-explosion box and spring lock design to safeguard experimental personnel and equipment. This structure greatly minimizes safety risks during the experiment. The test sequence can vary depending on the specific objectives, including adiabatic thermal runaway tests, adiabatic temperature rise tests, and more.

Monitoring and Recording Data During the Test

Throughout the testing process, the BAC-420AE consistently matches the theoretical temperature rise rate with an impressive error margin of less than 0.002℃/min. This precise control allows it to monitor and record minute changes in the battery during thermal runaway, providing essential data for analysis. The instrument’s modular design allows customization with additional modules like atmosphere simulation, specific heat capacity testing, and video monitoring, offering flexibility to meet diverse research needs.

Specifications

The specifications of the BAC-420AE underline its capabilities and versatility in battery safety testing:

- Adiabatic Furnace Size: 420mm diameter, 520mm depth.

- Exothermic Detection Sensitivity: 0.02°C/min to 0.05°C/min.

- Temperature Uniformity: Maintains a difference of less than 0.5°C between the furnace and the sample under constant temperature conditions.

- Temperature Control: Ranges from room temperature to 300°C, with a temperature tracking rate of 0.02°C/min to 13°C/min.

- Pressure Capability: Sealed canister accommodates a pressure range from 0 to 2 MPa.

- Needle Travel: Adjustable via software, ensuring precise control over test parameters.

- Current Range: The charge and discharge column supports a current range from -500A to 500A, catering to a wide variety of testing scenarios.

These features make the BAC-420AE a robust tool for comprehensively evaluating the thermal characteristics of lithium batteries, crucial for advancing battery technology and enhancing safety in new energy vehicles.

Applications and Future Directions

The Large Battery Adiabatic Calorimeter (BAC-420AE) stands as a pivotal instrument in the advancement of battery safety research, with potential applications and enhancements that promise to broaden its impact significantly.

Potential Applications of the BAC-420AE in Battery Safety Research

The BAC-420AE plays a pivotal role in testing both individual battery cells and battery packs, offering essential insights to mitigate the risk of thermal runaway—a significant concern in battery operations. It facilitates the acquisition of pertinent thermodynamic parameters and other data pertaining to the battery’s thermal runaway process. These findings aid researchers in gaining a deeper understanding of the thermal runaway risks associated with lithium batteries, thereby enhancing battery safety designs.

Moreover, they enable development personnel to conduct comprehensive assessments of the safety margins and failure risks associated with battery cells. Additionally, they assist users in implementing effective thermal management strategies and optimizing battery designs.

Integration with Other Testing Methodologies for Comprehensive Battery Safety Assessment

Integrating the BAC-420AE with other testing methodologies could create a more holistic approach to battery safety. By combining it with accelerated life testing and real-time monitoring systems, researchers can obtain a multifaceted view of battery performance and longevity. Linking these data points with cloud-based analytics platforms would enable the sharing of insights across the industry, fostering faster improvements in battery technology and safety standards.

In Closing Lithium Battery Explosion Test

The debut of the Large Battery Adiabatic Calorimeter (BAC-420AE) signifies a substantial progression in lithium battery safety testing. Featuring an innovative design with a pressure relief structure, advanced safety mechanisms, and meticulous temperature management, the BAC-420AE is set to revolutionize the evaluation of battery safety. It delivers detailed and trustworthy data on thermal runaway and other crucial safety metrics, facilitating the creation of safer and more efficient batteries. Designed to meet contemporary testing requirements, the BAC-420AE also possesses the flexibility to accommodate future technological developments, ensuring its ongoing significance and efficacy in enhancing battery technology and safety protocols across diverse sectors.