Lithium-ion Battery Testing: Ensuring Safety and Reliability

Lithium-ion batteries, serving as the cornerstone of contemporary electronics, hold a fundamental position in powering a vast array of devices, ranging from handheld smartphones to large-scale electric vehicles. Nonetheless, their extensive usage brings to the forefront the imperative responsibility of ensuring their operational safety, particularly when subjected to extreme or unconventional conditions. A significant element in verifying the safety of these batteries is the procedure known as thermal runaway testing, which plays a critical role in assessing potential risks. This blog explores the intricate processes involved in Lithium-ion Battery Testing, with a spotlight on thermal runaway testing, alongside the cutting-edge technologies implemented for comprehensive safety evaluations.

Lithium-ion Battery Testing is essential not only for manufacturers but also for consumers, as it safeguards the product’s longevity and mitigates threats such as excessive heat, fires, or even explosions, ensuring long-term reliability and safety for end-users.

The Critical Role of Thermal Runaway Testing

Comprehending the Phenomenon of Thermal Runaway

Thermal runaway describes a condition in which a battery’s temperature rises uncontrollably due to a variety of internal or external factors. This uncontrolled temperature surge has the potential to lead to serious, sometimes catastrophic, outcomes, including fires, explosions, and extensive damage to surrounding systems or equipment. Thermal runaway testing, therefore, is a pivotal process that examines the behavior of a battery when it is exposed to extreme heat or abnormal conditions, ensuring it can withstand these stressors without catastrophic failure.

By analyzing the battery’s response during thermal runaway, researchers can accurately assess the potential hazards, both in terms of likelihood and severity. Such testing is meticulously conducted in controlled environments to replicate real-world scenarios, thereby providing manufacturers with critical data concerning the battery’s safety performance under stress.

The Application of Adiabatic Calorimetry in Lithium-ion Battery Testing

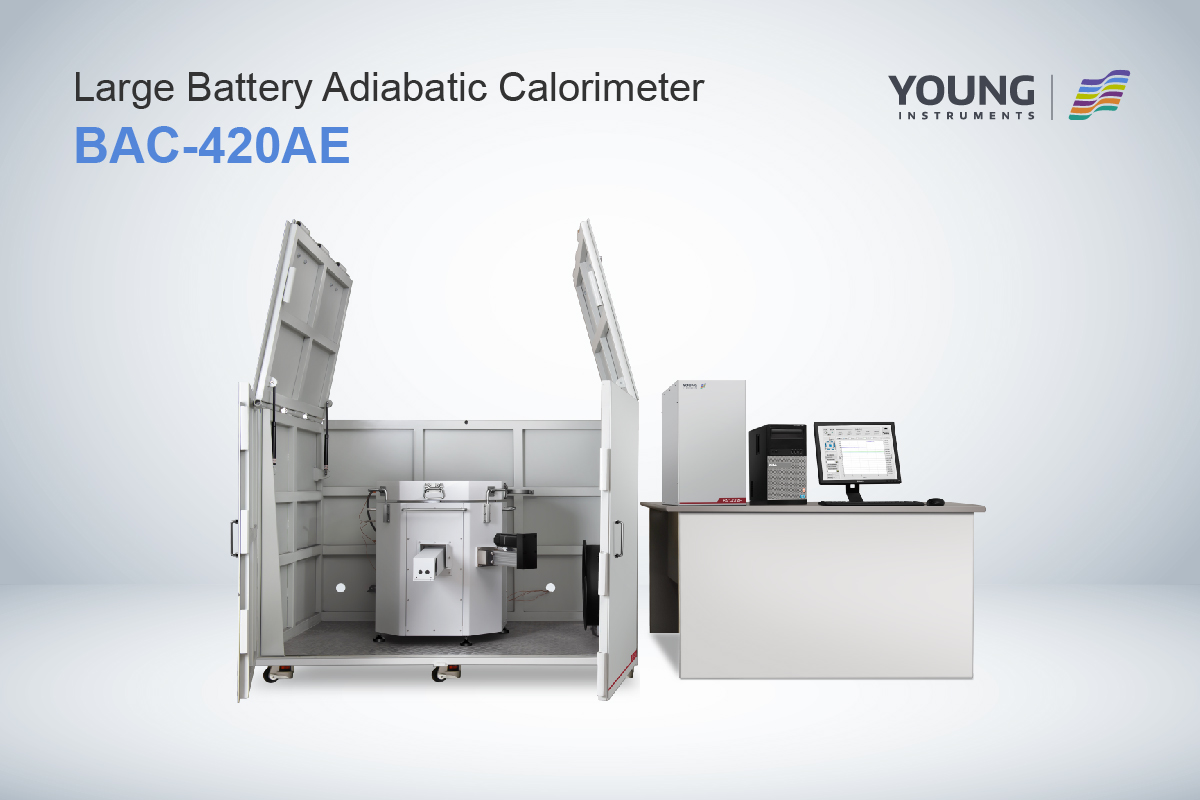

Adiabatic calorimetry, particularly through sophisticated instruments such as the Large Battery Adiabatic Calorimeter (BAC-420AE), plays a crucial role in the precise Lithium-ion Battery Testing. This method significantly reduces the influence of external environmental factors, allowing for a more accurate measurement of a battery’s thermal characteristics under high-stress conditions.

Using this advanced testing method, researchers are able to determine key thermal runaway parameters such as the initiation temperature points (T1, T2, T3), the maximum rate at which the temperature increases, and the total energy released during the runaway event. These quantifiable metrics offer a much more objective and reliable assessment of battery safety, in stark contrast to traditional methods that often rely on subjective indicators like the presence of smoke, fire, or physical damage.

The Benefits of Thermal Runaway Testing

One of the foremost advantages of thermal runaway testing is that it eliminates much of the subjectivity that typically accompanies safety evaluations. Traditional approaches, which rely heavily on visually observable phenomena such as smoke or flames, are far less precise. In contrast, thermal runaway testing generates solid, quantitative data that can be used to refine battery designs and optimize their safety performance based on defined metrics.

Moreover, this testing process allows for consistent comparison across various battery systems, capacities, and charge states, providing manufacturers with the ability to enhance the inherent safety features of their batteries. As a result, the likelihood of dangerous failures in real-world applications is significantly reduced, leading to a safer and more reliable product for consumers.

Advanced Testing Methods with the BAC-420AE

Multiple Abuse Testing Methods in One Instrument

The BAC-420AE, a cutting-edge calorimeter provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd., integrates multiple abuse testing methods that extend beyond mere thermal analysis. This advanced instrument not only supports thermal testing but also incorporates electrical and mechanical abuse testing, providing a comprehensive view of a battery’s safety performance. Furthermore, the calorimeter is equipped with visible and infrared imaging, gas collection systems, and specific heat testing functions, enabling detailed analysis of battery behavior under various stress scenarios.

The versatile capabilities of the BAC-420AE allow for the precise measurement of several critical parameters, including battery-specific heat capacity, heat generation during charging and discharging cycles, and adiabatic temperature rise. These measurements are crucial for understanding the underlying mechanisms that drive battery thermal runaway, ultimately leading to improved safety designs for lithium-ion batteries.

Real-Time Data Collection for Enhanced Analysis

A standout feature of the BAC-420AE is its ability to simultaneously collect real-time data on battery voltage, current, temperature, and pressure, offering an in-depth view of the thermal runaway process as it unfolds. This comprehensive data collection capability provides invaluable insights that enable researchers to continuously monitor the condition of the battery during testing.

In addition to these capabilities, the calorimeter also incorporates an integrated charging and discharging module that allows for seamless mode switching and precise adjustments in current and voltage. This enables manufacturers to test batteries under a variety of charging conditions, replicating real-world usage more accurately and ensuring the reliability and applicability of the test results.

Critical Parameters Measured

Thermal runaway testing with the BAC-420AE yields several important parameters that are essential for a comprehensive understanding of battery performance, including:

Thermal Runaway Onset Temperature: The temperature at which the battery begins to experience uncontrolled heating.

Maximum Rate of Temperature Rise: The steepest slope in the temperature increase, providing insights into how quickly the battery heats up during thermal runaway.

Adiabatic Temperature Rise: The total increase in temperature under adiabatic conditions, crucial for determining the thermal stability of the battery system.

These parameters provide researchers with detailed insights into the thermal behavior of the battery, facilitating more accurate and informed safety assessments.

Practical Applications in Lithium-ion Battery Testing

Testing of Battery Packs and Individual Cells

The BAC-420AE is versatile enough to accommodate testing both at the battery pack level and the individual cell level. This adaptability allows manufacturers to evaluate the thermal behavior of an entire battery system or focus on the specific safety characteristics of its individual components.

By simulating near-adiabatic conditions, the calorimeter provides precise thermal data that is critical for developing safer and more reliable battery systems. Manufacturers can use this data to compare different battery chemistries and capacities, determining which designs offer the optimal balance of performance and safety.

Charging and Discharging Testing Under Thermal Conditions

Lithium-ion batteries undergo various charging and discharging cycles throughout their lifespan. The BAC-420AE enables precise thermal testing during these cycles, offering manufacturers key insights into the heat generation that occurs at different charging rates.

When this data is combined with specific heat capacity measurements, it provides a complete picture of the total heat output during charging and discharging. Such information is vital for designing efficient battery management systems that ensure safe battery operation, even under high load conditions.

Gas Analysis During Thermal Runaway

A crucial aspect of thermal runaway is the release of gases, which can be flammable or even toxic. The BAC-420AE includes specialized features for gas collection and analysis, allowing researchers to measure the gas pressure, quantity, and composition during the runaway process.

This data is essential for evaluating the potential risks of explosion or fire. By understanding the chemical makeup of the released gases, manufacturers can develop effective containment strategies and improve the overall safety of battery enclosures, ensuring that any gas release is safely managed.

Conclusion: The Road to Safer Lithium-ion Batteries

As the global demand for lithium-ion batteries continues to grow, the need for robust and rigorous safety testing becomes even more critical. Thermal runaway testing, particularly with advanced techniques such as adiabatic calorimetry, plays an essential role in ensuring the safety of these batteries across a broad spectrum of applications.

With innovative tools like the BAC-420AE, provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd., manufacturers have access to comprehensive testing solutions that combine thermal, electrical, and mechanical abuse assessments with real-time data analysis. These tools enable the development of safer, more reliable battery technologies that meet the growing demands of industries from consumer electronics to electric vehicles.

The future of lithium-ion batteries lies in continuous innovation and stringent safety testing, ensuring not only compliance with safety standards but also paving the way for groundbreaking advancements in battery technology.