Microscale Continuously Closed Cup Flash Point Tester — Enhancing Maritime Engine Maintenance

Overview of Microscale Continuous Closed Flash Point Tester

In the realm of maritime transportation, ensuring the smooth operation of engines is paramount for safety and efficiency. However, the potential contamination of lubricating oil with fuel remains a persistent concern. To address this issue, the maritime industry requires efficient and reliable methods for continuously monitoring oil quality during voyages. The Microscale Continuous Closed Flash Point Tester (FP CC-420A) emerges as a solution, offering precise assessments of oil contamination levels promptly and safely.

Status of Oil Contamination Monitoring

The maritime sector faces the challenge of maintaining engine performance amidst the constant risk of lubricating oil contamination. This contamination can arise from various sources, including operational errors and slow fuel leakage into the engine crankcase. Traditional methods of flash point testing, such as the Pensky -Martens Closed Cup (PMCC) method, are inadequate for onboard use due to safety concerns and the need for large sample volumes.

- Safety Risks: Conventional testing methods involve flame ignition, posing a fire hazard, especially in the unpredictable conditions of maritime travel.

- Sample Volume and Testing Time: Large sample volumes and extended testing times increase the likelihood of spillage and are impractical for onboard testing.

- Inaccuracy: Traditional methods may not provide the precision and efficiency required to detect subtle changes in oil quality.

Needs for Onboard Oil Quality Monitoring

Efficient and accurate methods for monitoring oil quality are essential for maritime vessels to prevent engine damage and ensure operational reliability. These methods must address the unique challenges posed by onboard testing, including limited space, safety concerns, and the need for rapid results.

- Minimal Sample Volume: Onboard testers should require small sample volumes to minimize the risk of spillage and accommodate space constraints.

- Short Testing Time: Rapid testing procedures are crucial to minimize downtime and ensure timely assessments during voyages.

- Safety Measures: Testing equipment must employ safety features, such as non-flame ignition, to mitigate the risk of fire onboard vessels.

The Solution: Microscale Continuous Closed Flash Point Tester

The FP CC-420A Microscale Continuous Closed Flash Point Tester, manufactured by Zeal Instruments, addresses the shortcomings of traditional testing methods while meeting the specific needs of maritime oil quality monitoring.

- Microscale Testing: The tester requires only a minimal sample volume of 1-2mL, reducing the risk of spillage and accommodating onboard space limitations.

- Continuous Testing: With a testing time of approximately 10 minutes per sample, the FP CC-420A enables rapid and continuous monitoring of oil quality during voyages.

- Safety Assurance: Utilizing high-pressure electric ignition instead of an open flame, the tester ensures safety onboard vessels, minimizing the risk of fire accidents.

Experimental Section

- Raw materials: lubricating oil (MOBIL GARGOYLE ARCTIC OIL 300), diesel fuel.

- Standard solution preparation : a certain amount of lubricating oil and diesel fuel were aspirated separately with a pipette gun, mixed thoroughly and prepared to obtain 12 samples with diesel fuel volume concentration varying from 0% to 6% gradient.

- Experimental Instruments: Microscale Continuous Closed Flash Point Tester (FP CC-420A);

- Experimental method: astm d7094;

- Preset flash point values: maximum 210°C, minimum 140°C;

- Sample volume: 2.0mL ± 0.2mL;

- Rate of temperature increase: 2.5 °C/min ± 0.3 °C/min;

- Ignition frequency: 1℃;

- Critical value for flash ignition pressure rise detection: 20 kPa.

Testing Procedure

The above standard solutions were tested in order of diesel concentration from lowest to highest. Each sample is pipetted 2mL into the sample cup with a pipette gun, the expected flash point value is set, and the test is subsequently initiated. The instrument automatically completes the test procedure and the flash point value is automatically corrected to standard atmospheric pressure (101.3kPa) at the end of the test.

At the end of the current test, the sample cup is rinsed with anhydrous ethanol and baked and cleaned for 3 min at a temperature 10°C above the expected flash point value of the next sample to remove any residues that may be present in the test chamber. The sample is then loaded and the next sample is tested.

Results

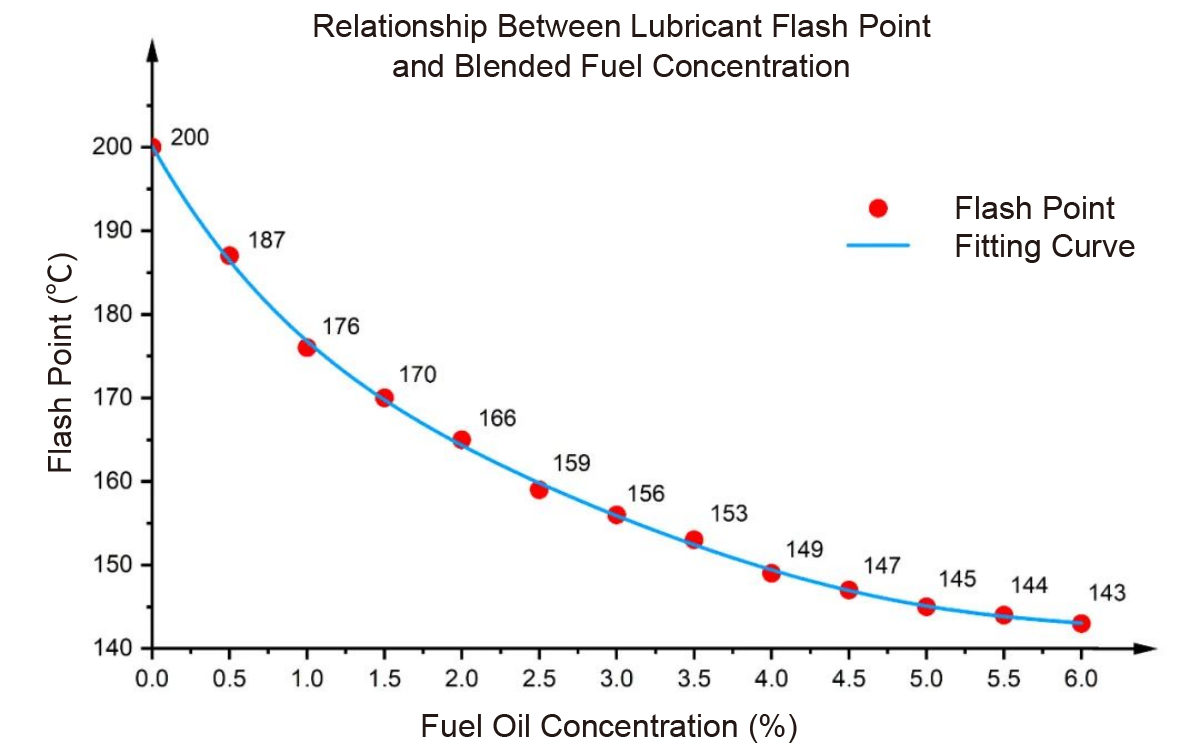

Figure 1 Relationship between lube oil closed flash point value and diesel fuel impurity concentration

As shown in Fig. 1, the variation of flash point value of lubricating oil with diesel impurity concentration can be obtained.According to the experimental results, it can be found that the more diesel content in the lubricating oil, the lower the flash point. This is due to the flash point of lubricating oil is usually above 200 ℃, the flash point of diesel fuel is generally between 45 ℃ ~ 120 ℃, a small amount of low-boiling point impurities mixed in will significantly reduce the flash point of high -boiling point substances [1]. At the same time through the test data can be established lubricant dilution model, when the flash point value of the unknown lubricant samples, the use of the model can determine whether the oil samples have been contaminated, and quantitatively analyze the degree of contamination.

Conclusion

The Microscale Continuous Closed Flash Point Tester, exemplified by the FP CC-420A, represents a significant advancement in maritime engine maintenance. By offering efficient, accurate, and safe oil quality monitoring, this technology helps mitigate the risks of engine damage and operational disruptions, ensuring the smooth sailing of maritime vessels in the modern era. As the industry continues to embrace innovation, the integration of IoT and data analytics holds promise for further enhancing onboard maintenance practices and optimizing vessel performance.

Reference

[1] Duan Xiaodong. Research on flash point characteristics of mixed liquid hazardous materials[J]. Journal of Shenyang University of Aeronautics and Astronautics,2017,34(06):87-91.