MIE Test Device: A Comprehensive Guide

If you work with combustible dusts, you know how important it is to assess their potential for ignition and explosion. One way to do this is by measuring the minimum ignition energy (MIE) of the dust. The MIE is the minimum amount of energy required to ignite a dust cloud under specific conditions, and it can vary depending on factors such as the type of dust, its concentration, and the presence of other flammable materials.

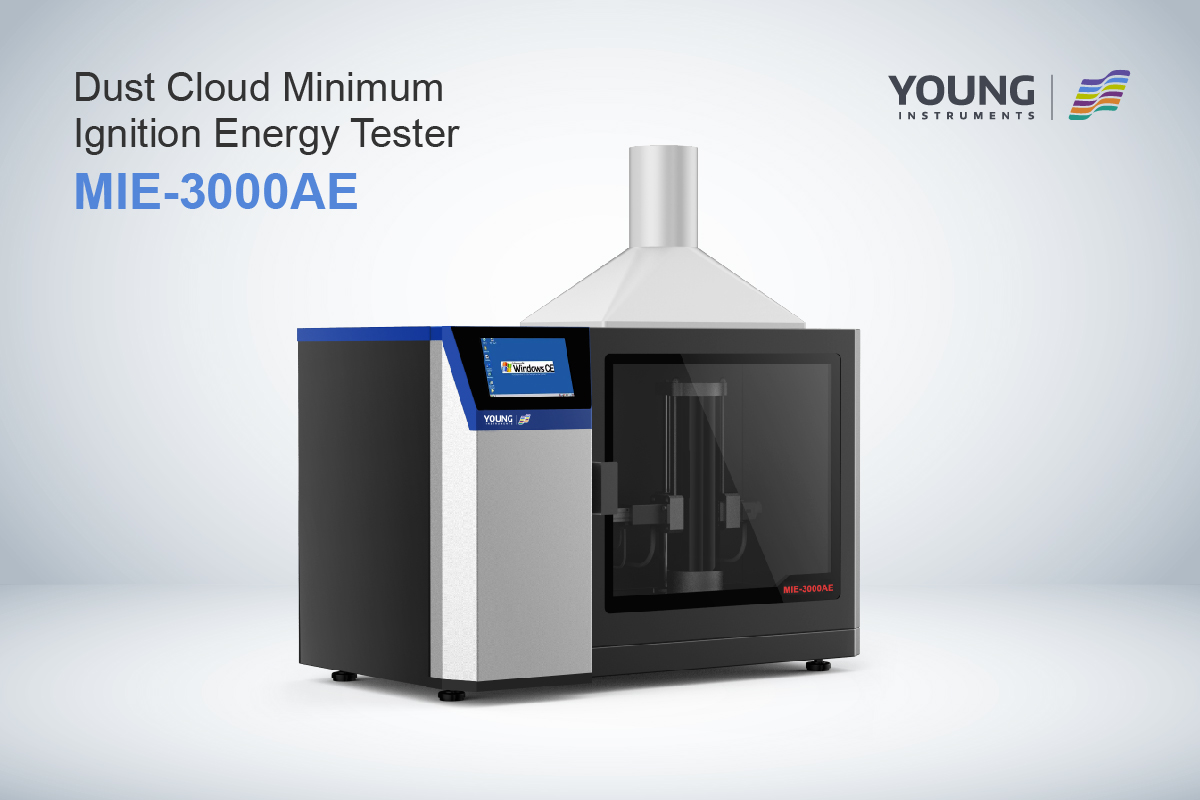

To measure the MIE, you need a specialized device that can generate sparks of varying energy levels and measure the minimum energy needed to ignite the dust. This is where the MIE test device comes in. These devices are designed to provide a safe and controlled environment for testing the ignitability of dusts, powders, and other flammable materials. They typically use capacitive discharge sparks to generate the required energy levels and can be customized to meet specific testing needs.

Overall, the MIE test device is a critical tool for anyone working with combustible dusts. By accurately measuring the MIE of a dust, you can better understand its potential for ignition and explosion and take appropriate safety measures to protect workers and facilities.

Overview of MIE Test Device

If you work with combustible dust or powders, you need to know their Minimum Ignition Energy (MIE). The MIE Test Device allows you to determine the minimum energy required to ignite a dust cloud. This information is essential for designing safe equipment and processes.

The MIE Test Device works by creating a dust cloud in a chamber and then applying a spark or arc to the cloud. The device measures the energy required to ignite the cloud. The test is repeated several times to determine an average MIE value.

To use the MIE Test Device, you need to prepare a sample of the dust you want to test. The sample is placed in the test chamber, and the chamber is sealed. The device then creates a dust cloud by using a fan or other means. The test is performed by applying an electrical discharge to the cloud, and the energy required to ignite the cloud is measured.

The MIE Test Device is an essential tool for anyone working with combustible dust or powders. It provides valuable information that can be used to design safe equipment and processes. By determining the MIE of a dust or powder, you can ensure that you are using safe operating conditions and equipment.

Design and Features

Hardware Specifications

The MIE test device is a specialized piece of equipment designed to measure the minimum ignition energy of combustible dust. It consists of a cylindrical tube, electrodes, and a high voltage power supply. The tube is filled with a sample of the combustible dust, and the electrodes are positioned at either end. The power supply delivers a high voltage spark to the electrodes, which ignites the dust. The minimum ignition energy is then determined by gradually decreasing the voltage until ignition no longer occurs.

The MIE test device is typically constructed from high-quality materials, such as stainless steel and aluminum, to ensure durability and longevity. It is also designed to be easy to use, with a simple interface and intuitive controls. Some models may also feature a digital display, which provides real-time feedback on the testing process.

Software Integration

In addition to its hardware specifications, the MIE test device may also feature software integration. This allows for greater control and customization of the testing process, as well as the ability to store and analyze data. The software may include features such as:

- Customizable testing parameters, such as voltage range and testing duration

- Real-time data monitoring and analysis

- Automatic data logging and reporting

- Integration with other testing equipment or laboratory software

Overall, the MIE test device is a powerful tool for measuring the minimum ignition energy of combustible dust. Its high-quality construction, intuitive design, and advanced software integration make it an essential piece of equipment for any laboratory or testing facility.

Operational Guidelines

Preparation and Setup

Before performing the MIE test, you need to make sure that you have all the necessary equipment and that it is properly set up. The following steps should be taken to prepare for the test:

-

Make sure that the MIE test device is clean and free of any debris or residue from previous tests. This can be done by wiping down the device with a clean, dry cloth.

-

Connect the MIE test device to a power source and turn it on. Allow the device to warm up for at least 10 minutes before starting the test.

-

Ensure that the test chamber is clean and free of any dust or debris. The test chamber should be completely sealed to prevent any air from entering or leaving during the test.

-

Set up the test sample according to the specifications outlined in the relevant standards, such as EN 13821 or ASTM E2019. The sample should be representative of the material being tested and should be prepared in a way that ensures consistency between tests.

Testing Procedures

Once you have prepared the MIE test device and the test sample, you can begin the testing procedures. The following steps should be taken to perform the MIE test:

-

Place the test sample in the test chamber and close the chamber door.

-

Set the MIE test device to the appropriate test parameters, such as the voltage and current, as specified in the relevant standards.

-

Press the test button to initiate the test. The MIE test device will generate a spark that will ignite the test sample.

-

Record the MIE value displayed on the MIE test device. This value represents the minimum energy required to ignite the test sample.

-

Repeat the test at least three times to ensure consistency and accuracy of the results.

-

Clean the test chamber and the MIE test device after each test to prevent contamination and ensure accurate results for future tests.

By following these operational guidelines, you can ensure that your MIE test results are accurate and consistent. Remember to always follow the relevant standards and procedures when performing MIE tests to ensure the safety of your personnel and equipment.

Performance Metrics

When it comes to medical devices, performance metrics are crucial to ensure the accuracy and reliability of the device. The MIE Test Device is no exception, and it boasts a number of performance metrics that make it a reliable tool for testing medical equipment.

Accuracy and Precision

- One of the most important performance metrics for any medical device is accuracy and precision. The MIE Test Device is designed to provide accurate and precise measurements of medical equipment, ensuring that your equipment is working as intended. The device has a built-in calibration system, which ensures that it is accurate to within 0.5% of the full-scale range.

- In addition to accuracy, the MIE Test Device also offers precision. The device has a resolution of 0.1% of the full-scale range, which means that it can detect even the smallest changes in your equipment’s performance. This level of precision ensures that you can identify any issues with your equipment before they become major problems.

Reliability and Maintenance

- Reliability and maintenance are also important performance metrics for any medical device. The MIE Test Device is designed to be reliable and easy to maintain, ensuring that you can use it for years to come.

- The device is constructed with high-quality materials, which means that it is durable and can withstand frequent use. Additionally, the device is easy to clean and maintain, which helps to extend its lifespan.

- Overall, the MIE Test Device is a reliable and accurate tool for testing medical equipment. Its performance metrics ensure that you can trust the results it provides, and its reliability and ease of maintenance make it a valuable addition to any medical facility.

Regulatory Standards

- When it comes to safety and compliance, the MIE Test Device must adhere to certain regulatory standards. The device must be designed and manufactured to meet the regulatory requirements set by the authorities. The regulatory standards that govern the MIE Test Device include the BS 5958 and BS EN 13821 standards. These standards outline the minimum requirements for the design, manufacture, and use of the device.

- The MIE Test Device must also comply with the ATEX Directive 2014/34/EU, which covers equipment and protective systems intended for use in potentially explosive atmospheres. The directive outlines the requirements for the design, manufacture, and use of equipment in such environments. The MIE Test Device must be designed and manufactured to meet the requirements of the directive, and must be marked with the appropriate ATEX markings.

User Safety Protocols

- In addition to regulatory standards, user safety protocols must also be followed when using the MIE Test Device. The device must be used by trained personnel who are familiar with the device and its operation. Users must follow the safety protocols outlined in the device manual to ensure safe operation.

- Users must wear appropriate personal protective equipment (PPE) when using the MIE Test Device. This includes safety glasses, gloves, and a lab coat. Users must also ensure that the device is used in a well-ventilated area to prevent the accumulation of potentially explosive dust clouds.

- The MIE Test Device must also be inspected and maintained regularly to ensure safe operation. Any damaged or worn parts must be replaced immediately, and the device must be calibrated regularly to ensure accurate results.

- Overall, the safety and compliance of the MIE Test Device is of utmost importance to ensure the safety of the users and the environment. By following regulatory standards and user safety protocols, the MIE Test Device can be used safely and effectively.