Minimum Ignition Energy Tester: What You Need to Know

If you work with flammable materials, you know how important it is to take safety precautions to prevent fires and explosions. One of the most essential tools for preventing explosions is the Minimum Ignition Energy (MIE) Tester. This device measures the minimum energy required to ignite a dust cloud, which is a critical factor in determining the likelihood of an explosion occurring.

The MIE Tester is an essential tool for anyone who works with flammable materials, such as in the chemical industry, agriculture, or manufacturing. It is designed to test the minimum amount of energy required to ignite a dust cloud, which is a key factor in determining the risk of a fire or explosion. By measuring this energy, you can take steps to ensure that your work environment is safe and that you are taking all necessary precautions to prevent accidents.

Whether you are a safety engineer, a plant manager, or a researcher, the MIE Tester is an essential tool for ensuring the safety of your workplace. By measuring the minimum ignition energy of your materials, you can take steps to prevent fires and explosions and protect your workers from harm. With the right MIE Tester, you can ensure that your work environment is safe and that you are taking all necessary precautions to prevent accidents.

Fundamentals of Ignition

Definition of Minimum Ignition Energy

The Minimum Ignition Energy (MIE) is a crucial safety characteristic in explosion protection and prevention. It determines the ignition capability of fuel-air mixtures, which can consist of combustible vapor, gas, or dust. MIE is defined as the minimum spark energy required to ignite an ideal concentration of a dust cloud under lab conditions. The test can be run with or without inductance, and a capacitive discharge spark is used for this test.

The MIE of flammable dust predicts the ease and likelihood of ignition of a dispersed dust cloud. The lower the MIE, the easier it is for the dust to ignite. The MIE value depends on various factors such as the particle size, shape, and chemical composition of the dust, as well as the atmospheric conditions.

Importance of MIE Testing

MIE testing is essential in industries where combustible dust is present, such as food processing, pharmaceuticals, and chemical manufacturing. The Occupational Safety and Health Administration (OSHA) requires employers to assess the hazards of combustible dust and take necessary measures to prevent dust explosions.

MIE testing helps identify the potential ignition sources and determine the level of risk associated with them. It also helps in selecting appropriate equipment and safety measures to prevent dust explosions. By knowing the MIE of a dust, the appropriate level of protection can be provided to prevent ignition sources from occurring.

In conclusion, MIE testing is a crucial safety measure in industries where combustible dust is present. By knowing the MIE of a dust, appropriate safety measures can be taken to prevent dust explosions and protect workers and equipment from harm.

MIE Tester Design

Components and Assembly

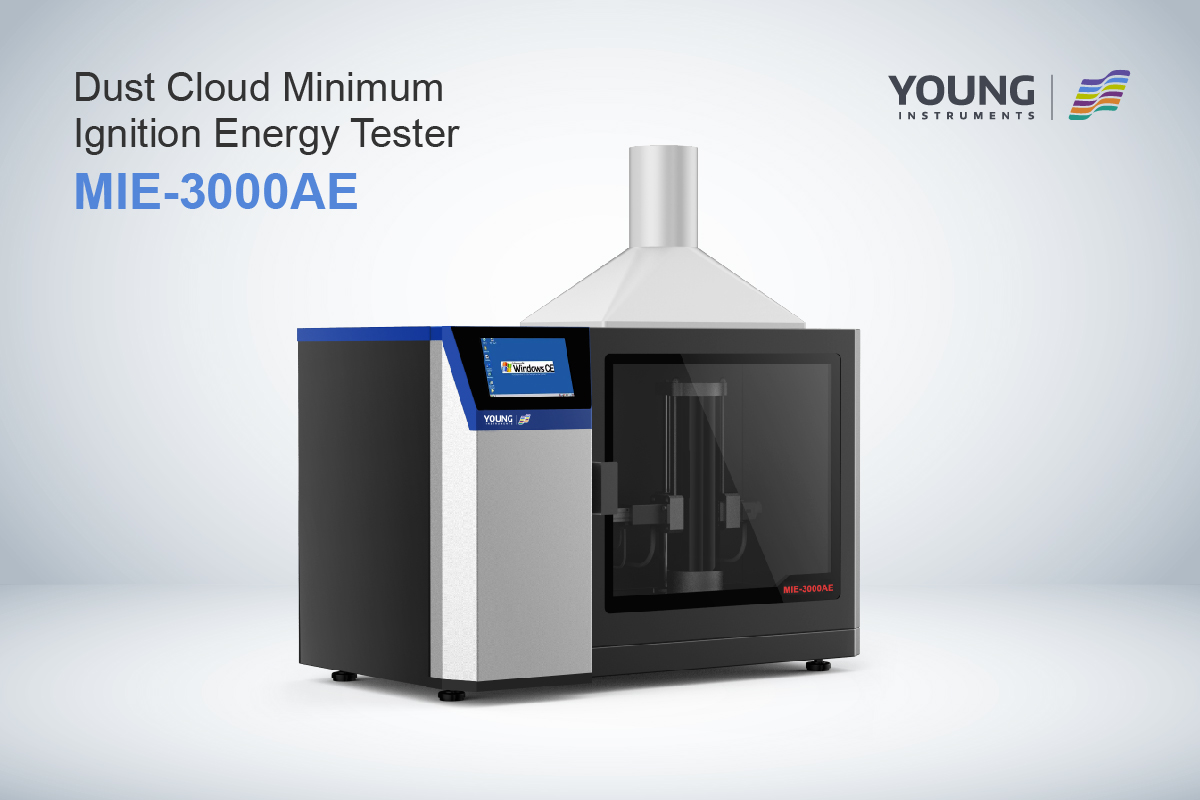

The Minimum Ignition Energy (MIE) Tester is a device used to determine the minimum energy required to ignite a dust cloud. The MIE Tester consists of several components, including a spark generator, a dust disperser, and a test chamber.

The spark generator produces a high voltage spark that is used to ignite the dust cloud. The dust disperser is used to create a uniform dust cloud inside the test chamber. The test chamber is a sealed container that is used to contain the dust cloud during testing.

The MIE Tester is assembled by connecting the spark generator to the dust disperser, and then connecting the dust disperser to the test chamber. The test chamber is then sealed to prevent any dust from escaping during testing.

Operating Principles

The MIE Tester operates on the principle that the minimum ignition energy required to ignite a dust cloud is directly related to the concentration of the dust cloud. The higher the concentration of the dust cloud, the lower the minimum ignition energy required to ignite it.

During testing, the dust disperser is used to create a uniform dust cloud inside the test chamber. The spark generator is then used to produce a high voltage spark, which is directed towards the dust cloud. The energy required to ignite the dust cloud is measured and recorded.

The MIE Tester is a valuable tool for assessing the risk of dust explosions in industrial settings. By determining the minimum ignition energy required to ignite a dust cloud, engineers and safety professionals can take steps to prevent dust explosions and protect workers and equipment.

Test Procedures

Sample Preparation

Before conducting any test, it is essential to ensure that the sample preparation is done correctly. The sample should be representative of the material and should be prepared according to the standard test method. The sample should be dry, free-flowing, and homogeneous. It is crucial to ensure that the sample is not contaminated with any other material that may affect the test results.

Execution of Tests

The execution of the test should be done according to the standard test method. The minimum ignition energy tester uses a high voltage spark to determine the minimum ignition energy of a dust cloud in air. The test method primarily assesses the likelihood of ignition during processing and handling.

During the test, the sample is dispersed into the test chamber, and the minimum ignition energy is determined by a high voltage spark. The ignition is determined by visual observation of a flame propagation away from the spark gap. The data developed by this test method may be used to assess the spark ignitability of a dust cloud.

It is essential to follow the test method precisely to ensure accurate results. The test method provides a procedure for performing laboratory tests to determine the minimum ignition energy of a dust cloud. It is crucial to note that for gases and vapors, a different test method should be used.

In conclusion, the test procedures for the minimum ignition energy tester are critical in ensuring accurate results. Proper sample preparation and execution of the test according to the standard test method are essential to assess the likelihood of ignition during processing and handling.

Data Analysis

Interpreting Results

Once the Minimum Ignition Energy (MIE) test is performed, the results need to be analyzed to determine the potential risk of a dust explosion. The MIE value obtained from the test indicates the minimum energy required to ignite a dust cloud. The lower the MIE value, the more easily the dust can ignite.

It is important to compare the MIE value obtained from the test to the MIE value of the actual dust present in the workplace. If the MIE value obtained from the test is lower than the MIE value of the actual dust, it indicates that the dust is highly explosive and poses a significant risk. In this case, appropriate safety measures need to be implemented to prevent dust explosions.

Safety Considerations

When interpreting the MIE test results, it is important to keep in mind the safety considerations. MIE testing involves the use of electrical sparks, which can be dangerous if not handled properly. It is crucial to follow all safety procedures and guidelines during the testing process to prevent accidents and injuries.

Furthermore, it is important to use appropriate personal protective equipment (PPE) when handling combustible dust. This includes wearing gloves, goggles, and respirators to protect against dust inhalation and skin contact. Proper ventilation and dust collection systems should also be in place to minimize the risk of dust explosions.

In summary, analyzing the MIE test results is crucial for assessing the risk of dust explosions in the workplace. It is important to compare the MIE value obtained from the test to the MIE value of the actual dust and implement appropriate safety measures to prevent accidents and injuries.

Applications and Limitations

Industrial Applications

The Minimum Ignition Energy (MIE) Tester is a widely used tool in the industry to assess the potential hazards of handling and processing flammable dusts. The MIE test determines the minimum amount of energy required to ignite a dust cloud in air by a high voltage spark. The MIE value is used to evaluate the likelihood of ignition during processing and handling, and to determine the need for explosion prevention measures such as inerting, venting, or suppression.

MIE testers are used in various industries such as chemical, pharmaceutical, food, and agriculture to assess the explosibility of dusts and powders. For example, in the food industry, the MIE test is used to determine the explosibility of flour, sugar, and other organic dusts that can accumulate in processing equipment and cause explosions. In the chemical industry, the MIE test is used to assess the explosibility of metal powders, such as aluminum and magnesium, that are used in various applications.

Limitations of MIE Testers

While the MIE test is a useful tool for assessing the explosibility of dusts and powders, it has some limitations that should be considered. The MIE value obtained from the test is based on ideal laboratory conditions, and may not reflect the actual conditions in the workplace. The test does not take into account the effects of humidity, temperature, particle size, and other factors that can affect the explosibility of dusts.

Moreover, the MIE test only determines the minimum amount of energy required to ignite a dust cloud, and does not provide information on the severity of the explosion or the potential damage that can be caused. Therefore, the MIE value should be used in conjunction with other explosion prevention measures, such as hazard analysis, risk assessment, and safety management systems.

In summary, the MIE Tester is a valuable tool for assessing the explosibility of dusts and powders in various industrial applications. However, its limitations should be considered, and it should be used in conjunction with other explosion prevention measures to ensure workplace safety.