MTSR Process Safety: Ensuring Safe Operations in the Workplace

MTSR process safety is a critical aspect of chemical process engineering. It refers to the maximum temperature that a chemical reaction can reach before it becomes uncontrollable and leads to a runaway reaction. This temperature is an essential parameter in designing and operating chemical reactors, as it helps to prevent hazardous conditions that can lead to explosions, fires, and other accidents.

Process safety is a crucial issue in the chemical industry, and MTSR provides a valuable tool for ensuring safe operations. By understanding the MTSR of a chemical reaction, engineers can design reactors that will operate safely under normal conditions and prevent catastrophic failures. Moreover, MTSR can be used to develop safety procedures, such as emergency shutdown procedures, to minimize the risk of accidents.

Overall, MTSR process safety is an essential aspect of chemical process engineering that ensures the safe operation of chemical reactors. It is a critical parameter that helps engineers design and operate reactors that will not pose a risk to workers, the environment, or the public. By understanding MTSR, engineers can develop safety procedures and protocols that will minimize the risk of accidents and ensure the safe and efficient operation of chemical processes.

Fundamentals of MTSR

When it comes to chemical process safety, the maximum temperature of the synthesis reaction (MTSR) is a critical parameter that must be taken into account. MTSR is defined as the maximum temperature that a reaction can reach before it becomes uncontrollable and potentially hazardous. In this section, we will discuss the fundamentals of MTSR, including risk assessment and safety management systems.

Risk Assessment

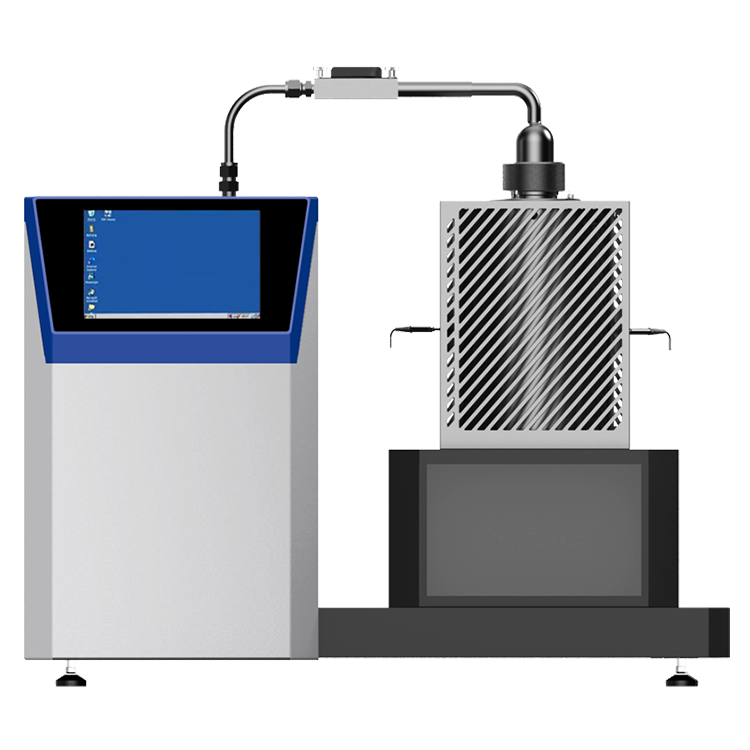

To assess the risk of a chemical process, it is important to determine the MTSR. This can be done through experimental testing or by using predictive models. Experimental testing involves measuring the temperature of a reaction as it is carried out under controlled conditions. Predictive models use data from previous experiments to estimate the MTSR for a given reaction.

Once the MTSR has been determined, it can be used to evaluate the risk of a chemical process. For example, if the MTSR is found to be close to the operating temperature of a reactor, it may be necessary to implement additional safety measures to prevent a runaway reaction.

Safety Management Systems

To manage the risk associated with chemical processes, safety management systems (SMS) are often implemented. An SMS is a set of policies, procedures, and practices that are designed to prevent accidents and protect workers and the environment. SMS should be tailored to the specific needs of each chemical process and should include measures to prevent and control runaway reactions.

One important aspect of an SMS is monitoring and control. This involves continuously monitoring the process and taking action if the temperature or other parameters deviate from safe levels. Other measures that can be incorporated into an SMS include emergency response plans, training programs for workers, and regular safety audits.

In summary, MTSR is a critical parameter that must be taken into account when assessing the risk associated with chemical processes. To manage this risk, safety management systems should be implemented that include measures to prevent and control runaway reactions.

Regulatory Framework

Legislation

When it comes to MTSR process safety, there are several regulations that you need to comply with. In the United States, the Occupational Safety and Health Administration (OSHA) has set regulations that apply to all industries, including chemical manufacturing. OSHA has established the Process Safety Management (PSM) Standard, which requires employers to develop and implement a process safety management program that includes a hazard analysis, operating procedures, training, and management of change procedures.

Additionally, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act that require facilities to implement risk management plans (RMPs) for certain chemicals. These regulations are designed to prevent accidental chemical releases and ensure that facilities have adequate emergency response plans in place.

In Europe, the European Union has established the Seveso III Directive, which requires companies that handle hazardous substances to identify and assess the risks associated with their activities and to take measures to prevent accidents and limit their consequences. The directive also requires companies to establish emergency plans and to inform the public about the risks associated with their activities.

Compliance Requirements

To comply with these regulations, you will need to implement a process safety management program that includes the following elements:

- Hazard identification and assessment: You will need to identify the hazards associated with your processes and assess the risks associated with those hazards. This will involve conducting a hazard analysis and developing a process safety information document.

- Operating procedures: You will need to develop and implement written operating procedures that describe the steps necessary to safely operate your processes. These procedures should include instructions for startup, shutdown, and emergency situations.

- Training: You will need to provide training to your employees on the hazards associated with your processes and the procedures necessary to safely operate those processes.

- Management of change: You will need to establish procedures for managing changes to your processes, including changes to equipment, procedures, and chemicals.

- Emergency planning and response: You will need to develop and implement an emergency response plan that includes procedures for responding to chemical releases and other emergencies.

By complying with these regulations and implementing a comprehensive process safety management program, you can help protect your employees, your facility, and the surrounding community from the risks associated with MTSR processes.

Implementation Strategies

Resource Allocation

Implementing the MTSR process safety requires a significant allocation of resources. This includes personnel, equipment, and financial resources. You need to allocate the necessary resources to ensure that your MTSR process safety program is successful.

First, you need to assign a team of experienced personnel to oversee the implementation of the MTSR process safety program. The team should include individuals with expertise in process safety, risk assessment, and emergency response.

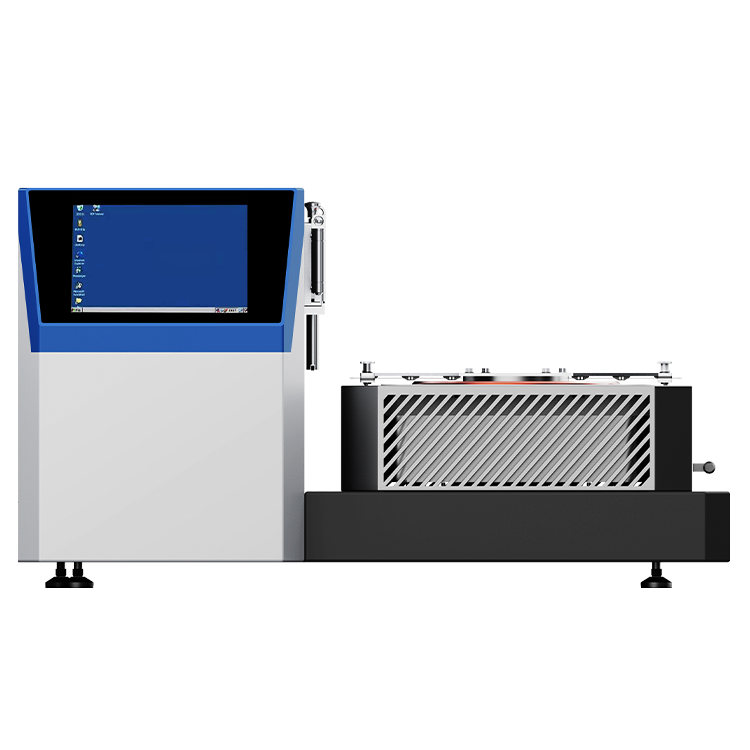

Second, you need to ensure that the necessary equipment is available to implement the MTSR process safety program. This includes equipment for monitoring and controlling process conditions, such as temperature and pressure. You should also have equipment available for emergency response, such as fire suppression systems and personal protective equipment.

Finally, you need to allocate the necessary financial resources to implement the MTSR process safety program. This includes funding for personnel, equipment, and training. You should also allocate funds for ongoing maintenance and upgrades to ensure that the MTSR process safety program remains effective.

Training and Communication

Effective training and communication are critical to the success of the MTSR process safety program. You need to ensure that all personnel involved in the MTSR process are properly trained in process safety, risk assessment, and emergency response.

Training should be ongoing and should include regular refresher courses to ensure that personnel remain up-to-date with the latest safety procedures and protocols.

Effective communication is also critical to the success of the MTSR process safety program. You need to ensure that all personnel involved in the MTSR process are aware of the potential hazards and risks associated with the process.

This includes communicating the results of risk assessments and emergency response plans. Effective communication also involves establishing clear lines of communication between personnel involved in the MTSR process, as well as with external stakeholders, such as emergency responders and regulatory agencies.

Overall, implementing an effective MTSR process safety program requires a significant allocation of resources and a commitment to ongoing training and communication. By following these strategies, you can help ensure the safety of your personnel and the surrounding community.

Monitoring and Improvement

To ensure the safety of your MTSR process, monitoring and improvement are crucial. By regularly monitoring your process, you can identify potential hazards and take steps to prevent accidents. Here are some ways to monitor and improve your MTSR process:

Performance Indicators

Performance indicators can help you track the safety of your MTSR process. Some examples of performance indicators include the maximum temperature of the synthesis reaction (MTSR), time-to-maximum rate (TMR), and maximum technical temperature (MTT). By monitoring these indicators, you can identify potential hazards and take steps to prevent accidents.

Audit and Review

Regular audits and reviews can help you identify areas where your MTSR process can be improved. During an audit, you can review your safety procedures and identify any gaps or weaknesses. You can then take steps to address these issues and improve the safety of your process.

Reviews can also help you identify ways to improve the efficiency of your MTSR process. By reviewing your process, you can identify areas where you can streamline operations and reduce the risk of accidents.

Overall, monitoring and improvement are critical to the safety and efficiency of your MTSR process. By regularly monitoring your process and conducting regular audits and reviews, you can identify potential hazards and take steps to prevent accidents.