Oxygen Bomb Calorimeter: Precision in Calorific Value Measurement

The precise determination of energy content within a substance is a critical requirement for both scientific exploration and numerous industrial procedures. Every physical material, due to its inherent nature, contains energy that can be quantified by analyzing the heat emitted during combustion. The oxygen bomb calorimeter is a highly specialized apparatus designed specifically to measure this calorific value with exceptional precision. By enclosing the material inside a hermetically sealed vessel, known as an oxygen bomb, and inducing combustion within this environment, the subsequent release of heat is captured and analyzed to calculate the energy content of the material in question.

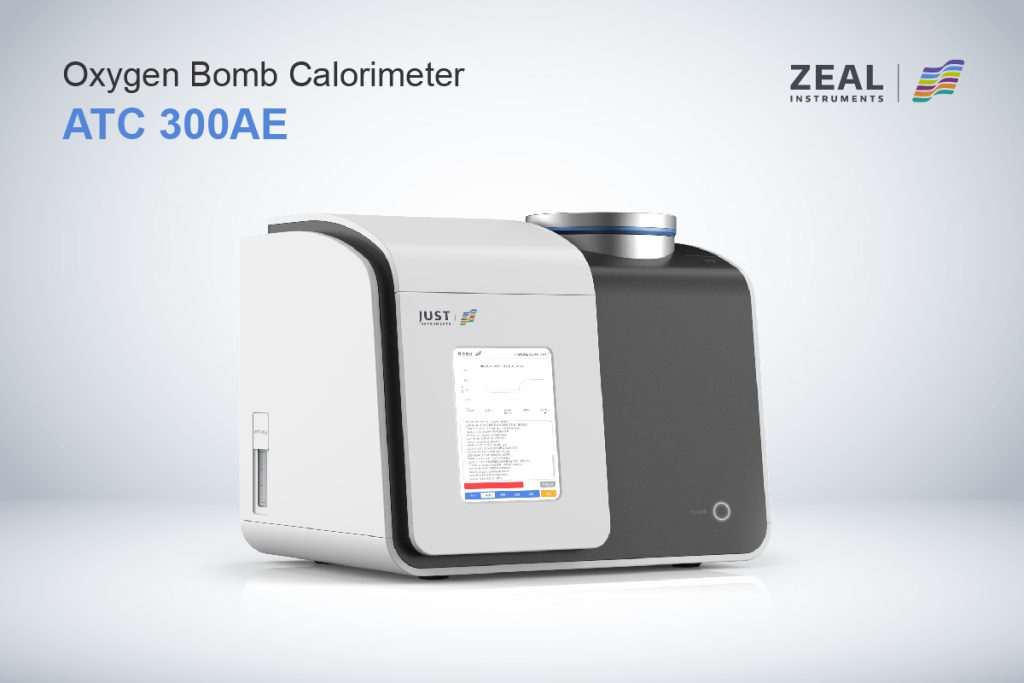

The ATC 300AE Oxygen Bomb Calorimeter: A Leading-Edge Instrument

Features of the ATC 300AE

Provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd., the ATC 300AE Oxygen Bomb Calorimeter is a state-of-the-art instrument that embodies the latest advancements in calorimetric technology. It adheres to rigorous international standards, including GB/T 384, GB/T 213, ASTM 4809, and ASTM D240, ensuring that it meets the diverse needs of various industries by delivering reliable and accurate calorific measurements. Among the many noteworthy characteristics of the ATC 300AE is its highly automated design, which not only simplifies the operational process but also ensures a high level of consistency in the results.

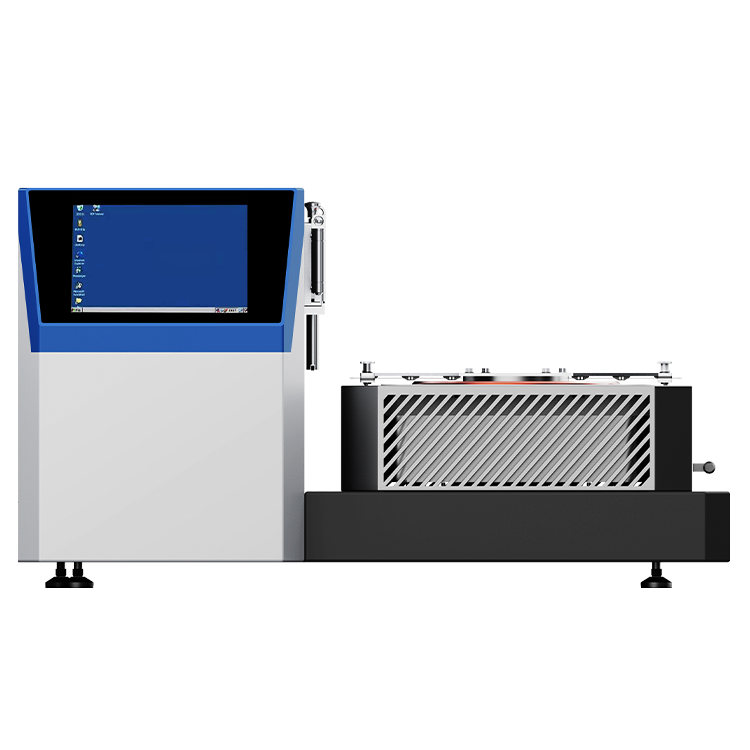

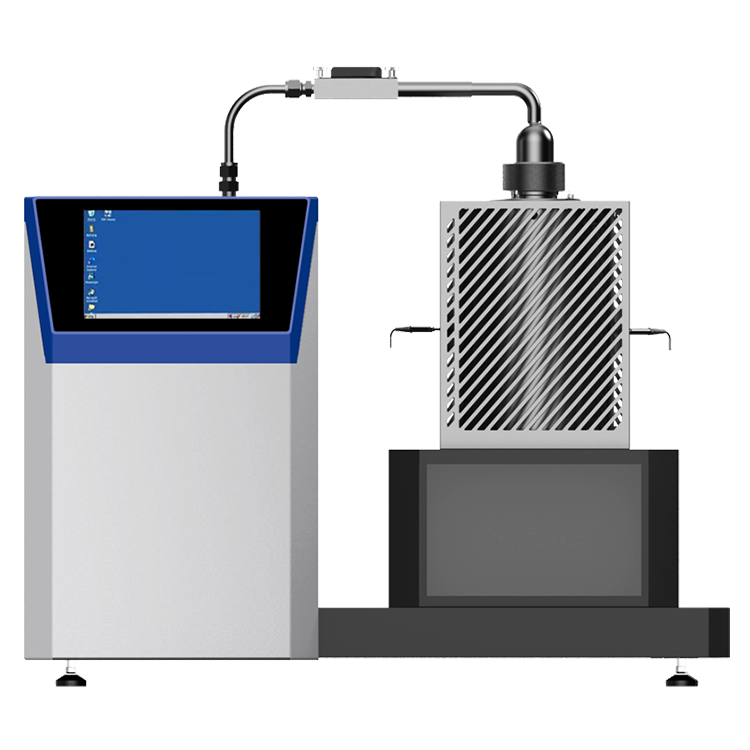

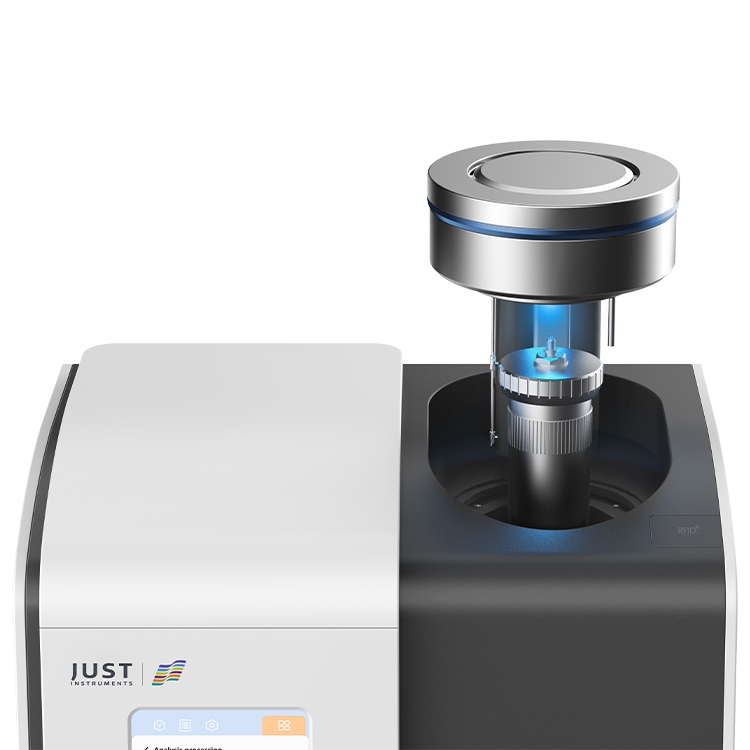

This advanced calorimeter is equipped with a sophisticated temperature control system that facilitates rapid and precise temperature measurements. Its fully automated features, which include the automatic lifting and lowering of the oxygen bomb, automated oxygen filling, and real-time pressure detection, help streamline the measurement process, thereby reducing potential human errors. The high degree of automation not only enhances accuracy but also improves user convenience, positioning the ATC 300AE as an ideal solution for both laboratory and industrial environments.

Unmatched Precision and Speed

One of the primary advantages of the ATC 300AE Oxygen Bomb Calorimeter lies in its ability to combine speed with precision. With testing times kept under 10 minutes, the instrument ensures swift results without sacrificing accuracy. The automated design, including the automatic recognition of the oxygen bomb’s identification number, further simplifies the process, enabling users to quickly carry out analyses in situations where time is a critical factor.

The calorimeter employs a semiconductor-based water temperature balancing system, complete with high-efficiency filtration, to ensure that the measurement of heat capacity remains exceptionally precise. The real-time recording of temperature variations during combustion allows the system to quickly respond to these changes, ensuring consistent and repeatable results. Additionally, the ATC 300AE is equipped with a dual control system that enables synchronized monitoring of the entire experimental process, thereby enhancing the overall integrity of the collected data.

Advanced Data Handling and User Interaction

The ATC 300AE integrates advanced software features that significantly simplify the handling and processing of experimental data. This intelligent system automatically corrects measurement data and provides users with three distinct types of calorific values: high calorific value, low calorific value, and bomb calorific value. The ability to display data curves in real-time offers continuous insight into the combustion process, while the system’s automatic data generation and storage capabilities ensure that historical data can be easily retrieved for further analysis.

A user-friendly touchscreen interface simplifies experiment monitoring and control, making the ATC 300AE accessible to both seasoned professionals and new users. Moreover, the calorimeter includes essential safety features such as automatic ignition wire detection and short-circuit protection, ensuring that experiments are conducted in a safe and secure environment.

Applications and Adaptability of the ATC 300AE Oxygen Bomb Calorimeter

Broad Range of Industrial Applications

The versatility of the ATC 300AE Oxygen Bomb Calorimeter makes it suitable for use across a wide array of industries. Its capacity to measure the calorific value of various substances with high precision has rendered it an indispensable tool in fields such as coal testing, where the accurate determination of energy content is critical for assessing fuel efficiency and suitability for power generation. In the biomass fuel sector, precise calorific measurements allow for the optimization of fuel usage, ultimately contributing to more efficient energy production.

In the food industry, the ATC 300AE proves invaluable by enabling the accurate measurement of the calorific content of food products, a key requirement in nutritional analysis and quality control. Additionally, the calorimeter’s capabilities extend to the waste management sector, where understanding the energy potential of waste materials plays a pivotal role in maximizing the efficiency of energy recovery processes.

Tailored Solutions for Energetic Materials

Beyond its conventional applications, the ATC 300AE Oxygen Bomb Calorimeter can be customized for specialized tasks, particularly those involving energetic materials. Hangzhou Zeal Instruments offers tailored modifications that enable the instrument to withstand the extreme temperatures, pressures, and shock waves generated during the combustion of high-energy substances such as propellants, explosives, and pyrotechnics. This versatility makes the ATC 300AE an essential tool for researchers working with energetic materials, as it allows for the precise measurement of calorific values and a comprehensive evaluation of combustion performance.

The calorimeter’s ability to endure and accurately measure under extreme conditions makes it indispensable for industries that require detailed analysis of hazardous and high-energy materials. This adaptability ensures that the ATC 300AE remains relevant in a wide variety of research and industrial contexts.

The Science Behind Calorimetric Measurement: Understanding the Oxygen Bomb Calorimeter

The operational concept behind the oxygen bomb calorimeter revolves around the direct correlation between the thermal energy discharged during combustion and the corresponding temperature variation in the surrounding system. Through the incineration of a substance with a previously established calorific value, the device accurately gauges the fluctuation in temperature within its system, enabling a precise calculation of the heat absorbed per unit increase in temperature. Following calibration with a standard reference substance, the instrument can subsequently combust an unknown material, recording the temperature change and thereby determining the calorific value of the substance under investigation.

Core Concepts in Calorimetric Measurement

At the heart of calorimetric evaluation lies a straightforward yet scientifically robust principle: the controlled combustion of material inside an enclosed, regulated environment, such as the oxygen bomb. During this process, the material combusts in a pure oxygen atmosphere, releasing energy in the form of heat, which in turn causes a measurable rise in the system’s temperature. The high precision inherent in the design of the oxygen bomb calorimeter enables researchers and technicians alike to ascertain the exact amount of heat necessary to elevate the system’s temperature by a single unit, an essential metric in accurate energy measurement.

To guarantee precision, the system initially combusts a standard reference material with a known calorific value. The thermal energy released from this known entity is employed to calibrate the calorimeter by calculating the heat absorbed per degree of temperature change based on the observed temperature fluctuations. Once this essential calibration step is completed, the device is fully prepared to measure the energy content of other substances by analyzing the temperature variations resulting from their combustion.

The Significance of Measuring Calorific Value

Accurately determining the calorific value of materials is a fundamental requirement across a multitude of industries. In areas such as coal processing, biomass fuel production, and waste management, a comprehensive understanding of a material’s energy content is directly linked to improvements in efficiency and overall performance. Accurate calorific measurement allows for the optimization of fuel consumption, aids in the evaluation of environmental impact, and ensures compliance with energy-related regulations. In the realm of scientific research, the ability to precisely quantify calorific values is crucial for exploring material properties and predicting the potential energy released during combustion.

The oxygen bomb calorimeter has garnered widespread recognition as one of the most accurate instruments for measuring energy content, making it an indispensable tool across a variety of fields, including fuel research, material science, and environmental testing. Its capacity to consistently deliver reliable results ensures its continued use in critical industrial and scientific applications.

Conclusion

The ATC 300AE Oxygen Bomb Calorimeter, provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd., represents an innovative and highly advanced solution for the precise measurement of calorific values across a multitude of industries. Its sophisticated automation, fast testing times, and advanced temperature control system make it an efficient and reliable tool for applications ranging from traditional fuel testing to the analysis of energetic materials. By delivering consistent and accurate results, the ATC 300AE plays a crucial role in optimizing research processes and enhancing the safety and efficiency of industrial operations.