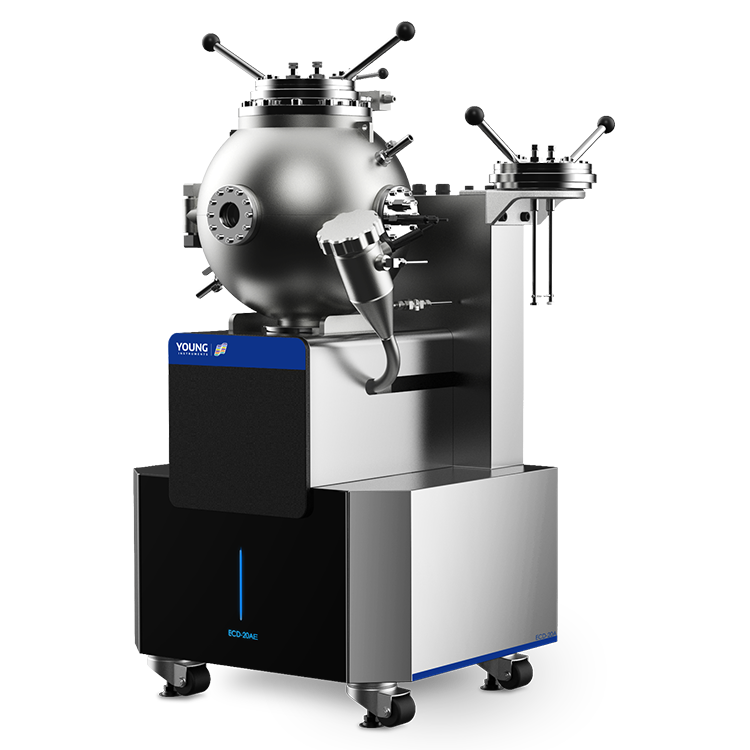

20L Spherical Explosion Tester

The ECD-20AE is a professional instrument for determining the maximum explosion pressure maximum rate of explosion pressure rise, and explosion index of dust clouds under specific test conditions. Suitable for assessing dust explosivity in production sites of aluminum powder, zinc powder, plastic powders, and organic synthetic pharmaceutical intermediates, it accurately measures parameters like maximum explosion pressure, maximum rate of explosion pressure rise, explosion index, lower explosion limit, and limiting oxygen concentration.

Test Parameters

Maximum Explosive Pressure, Maximum Explosive Pressure Rate of Rise, Explosive Index

Applicable Fields

Combustible Dust

Keywords

Combustible Dust Explosion, Combustible Dust Classification, Dust Testing

Features

Specifications

| Operating Environment | 5°C – 45°C, <85% RH |

| Explosive Container | 20 L Ball with jacket |

| Vessel Pressure Resistance | ℃Design pressure 3.0 MPa @ 25°C |

| Ball Material | Stainless steel 316 |

| Ball Working Temperature | Maximum temperature 220 ℃ |

| Sphere Volume | 20 L |

| Mezzanine Volume | 1.5 L |

| Diffusion Pressure Sensor | Range 0–3.5 MPa, overload pressure 10.5 MPa, accuracy ±0.1% FS, operating temperature -40–105 °C |

| Explosion Pressure Detection | Detection range 0–10.0 MPa, resolution 0.001 MPa, accuracy ±0.5% FS, response time < 20 µs |

| Explosive Pressure Detection Channels | 2 |

| Explosion Temperature Sensor | Detection range 0°C – 1000°C, resolution 0.01 °C |

| Dust Diffusion Vessel | Capacity 0.6 L, pressure resistance 2.5 MPa |

| Powder Spraying Pressure | 2 MPa |

| Nozzle Type | Bounce Nozzle |

| Powder Spraying Delay Time | 30–50 ms |

| Ignition Method | Chemical ignition (customer’s own); Electrostatic Ignition (15 kV, 0.5 s) |

| Ignition Delay Time | 60 ms |

| Explosive Pressure Data Acquisition | Maximum acquisition rate 100 ks/s, recording time 1 s |

| Ignition Control | Support remote wireless ignition |

| Automatic Air Distribution | 2 gas inlets, 1 air inlet; adopts partial pressure method of air distribution, with independent pressure sensors and solenoid valves, air distribution accuracy ± 0.1% |

| Vacuum System | Rotary vane vacuum pump, equipped with double impact filters to prevent residual substances from clogging and contaminating the pipeline, and easy to replace |

| Snap Ring Diameter | 95 mm |

| Cleaning Hole Diameter | 150 mm |

| Viewing Window | Armoured glass, 40 mm diameter |

| Interface | RJ45 |

| Power Supply | 90~260VAC/47~63Hz |

| Power | 600 W |

| Dimensions | 700 mm × 540 mm × 1210 mm |

Applications

No information!

Videos

No information!

Download

No information!

Q&A

No information!