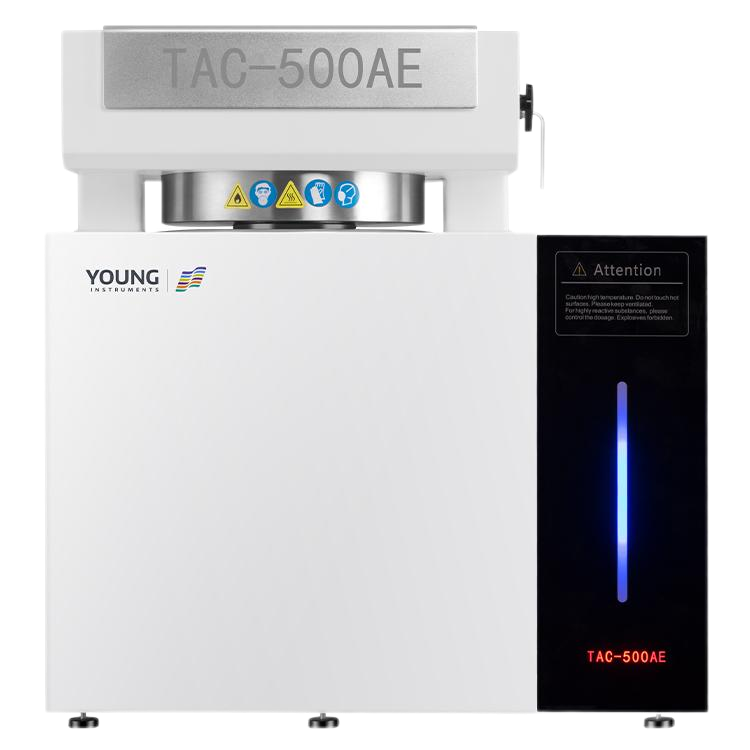

ARC Calorimeter

The Accelerating Rate Calorimeter (ARC) is a high-precision thermal analysis instrument specifically designed for studying chemical reactions, material thermal stability, and battery safety. ARC simulates potential thermal runaway reactions under laboratory conditions, obtaining true and complete data on heat and pressure changes during adiabatic thermal runaway processes. It accurately calculates key thermal safety indicators such as TD24, TMRad, and SADT.

Test Parameters

Process and Safety Assessment, Thermodynamic Calculations, Runaway Reactions

Applicable Fields

Risk Assessment of Reactions, Pharmaceuticals, Food and Organic Synthesis, MTSR Process Safety

Keywords

Adiabatic Calorimeter, Thermal Stability Testing, ARC Calorimeter

Description

Uses

The ARC Calorimeter is a versatile, flexible, and relatively low-cost instrument widely used in the research and optimization of chemical processes in fields such as fine chemicals, petrochemicals, agricultural fertilizers, polymers and plastics, and energetic materials. It is also used for the effective assessment of thermal hazards during the storage and transportation of chemicals and for scientific research on the thermokinetics of chemical reactions.

- Chemical Reaction Kinetics Research: Measures the rate of chemical reactions, exothermic behavior, and reaction endpoints.

- Material Thermal Stability Analysis: Studies the thermal degradation characteristics of polymers, explosives, and energy storage materials.

- Thermal Hazard Assessment: Determines the safety of chemicals under various environmental conditions.

Application Notes

Before the experiment, it is necessary to select appropriate experimental conditions based on the characteristics of the sample and ensure that the instrument is properly calibrated. During the experiment, data should be continuously monitored and experimental parameters adjusted in a timely manner. After the experiment, the instrument should be thoroughly cleaned and maintained.

- Samples should be pre-treated to ensure that they are free from contamination and impurities that could affect the test results.

- The experimental environment should be kept dry and well-ventilated to prevent the accumulation of volatile substances.

- During the test, the temperature rise rate should be strictly controlled to ensure experimental safety.

- After the experiment, the equipment should be cleaned to prevent residues from contaminating the next test.

Maintenance Guide – Sample Cup Cleaning

- After the experimental test is completed, lift the furnace cover. Connect the air compressor to the instrument’s cooling port to quickly cool the instrument to a safe temperature. Open the pressure relief valve to release the high-pressure gas.

- Use the provided wrench to remove the sample cup. Pour the liquid or solid samples or products into the waste liquid pool. Clean the sample cup with alcohol or another organic solvent. If conditions permit, an ultrasonic cleaner can be used to prevent cross-contamination from multiple experiments.

Maintenance Guide – Cleaning of Piping and Fittings

The instrument is equipped with two sets of exhaust piping. After each experiment, the used piping should be removed and replaced with the spare set to continue testing, thereby increasing overall experimental efficiency. The removed piping should be cleaned with an organic solvent that is miscible with the experimental sample and then air-dried. If conditions permit, an ultrasonic cleaner can be used for cleaning.

Maintenance Guide – Furnace Cleaning

In case of sample cup explosion, sample spillage during loading/unloading, or any other contamination of the furnace, clean the furnace promptly to prevent damage to the furnace thermocouples due to prolonged soaking in corrosive liquids.

Precautions

- During the instrument cooling process, the power must remain on.

- After the experiment, lift the furnace cover and use compressed air or inert gas for cooling. Since the instrument’s components are still very hot at this time, experimenters should avoid approaching the instrument to prevent burns.

Features

Specifications

| Working Environment | 5°С to 40°С, <85%RH |

| Temperature Range | RT to 500 °С |

| Temperature Detection Threshold | 0.005°С/min to 0.02°С/min |

| Temperature Tracking Rate | 0.005°С/min to 40°С/min |

| Temperature Resolution | 0.001°С |

| Pressure Detection Range | 0 to 20000kPa |

| Pressure Resolution | 1kPa |

| Sample Test Amount | 8mL |

| Material of Test-cell | Stainless Steel, Titanium Alloy, Hastelloy (optional) |

| Phi | ≤1.35 |

| Interface | USB or RJ45 |

| Power Supply | AC220V/50Hz |

| Power | ≤3000W |

| Dimensions | 620mm x 470mm x 670mm |

| Weight | Approx. 78kg |

Applications

Videos

Instruction

Adiabatic acceleration calorimeter

TAC-500A