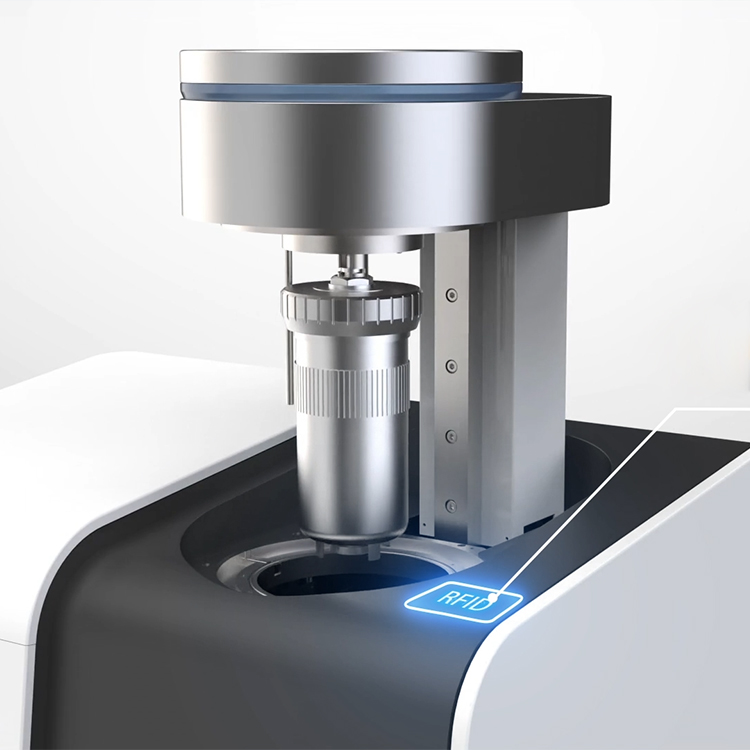

Automatic Calorimeter

The Automatic Calorimeter is a high-precision, intelligent energy measurement device widely used in industries such as coal, power, chemical, building materials, food, and research institutions. It features an advanced automated control system that enables the full automation of the testing process, significantly enhancing testing efficiency and minimizing human error.

Test Parameters

Calorific Value

Applicable Fields

Coal, Metallurgy, Construction, Petrochemical

Keywords

Bomb Calorimeter, Laboratory Calorimeter, Calorimeter Instrument, Bombenkalorimeter

Description

Scope of Application

- Coal and Mining: For the calorific value determination of coal, coke, and solid fuels, to evaluate fuel quality.

- Oil and Chemicals: Measurement of the calorific value of fuel oil, lubricants, and chemical products, to optimize energy utilization.

- Biomass Energy: Assessment of the calorific value of renewable energy sources such as straw, wood chips, and refuse-derived fuel (RDF).

- Environmental Science: Analysis of the calorific value of waste materials like garbage and sludge, to assess their energy conversion potential.

- Food and Agriculture: Measurement of the energy value of food and feed, providing data support for nutritional research.

Testing Procedure

- Turn on the ATC 300A Automatic Oxygen Bomb Calorimeter.

- Weigh a specific amount of the sample in the sample cup, connect the ignition wire to the sample with cotton thread, and secure it.

- Step 2: Install the oxygen bomb, set the experimental parameters, and enter information such as the sample mass.

- Step 3: Start the experiment. Once the testing environment is ready, the instrument will conduct the test automatically.

- Step 4: After the experiment concludes, remove the oxygen bomb, clean it, and record the experimental data.

Caveat

- Ensure the oxygen bomb is well-sealed before the test to prevent oxygen leakage.

- Use only high-purity oxygen (≥99.5%) to avoid contamination that could affect test results.

- Grind the sample evenly to prevent uneven combustion and testing errors.

- Follow the recommended sample weight range to avoid inaccuracies due to overloading or insufficient sample.

- Operate the device in a well-ventilated laboratory to prevent the accumulation of exhaust gases.

- Clean the oxygen bomb promptly after testing to remove carbon deposits that could affect precision.

- Calibrate the device regularly to ensure long-term testing accuracy meets standards.

Sample Request

- Sample Type: Solid or liquid fuels.

- Sample Weight: 0.5–1.5 g.

- Sample Preparation: Ensure the sample is dry, homogeneous, and free from external contaminants.

- Sample Storage: Store in a sealed container to prevent moisture or contamination.

Ordering Guide

- Confirm Required Accessories: Standard benzoic acid, oxygen bomb, spare ignition wire, and other accessories can be purchased as needed.

- Customization: For special testing requirements, consult the manufacturer for customized solutions.

- After-Sales Service: Understand the product warranty period and technical support services to ensure worry-free long-term use.

- Transportation and Installation: Confirm the delivery method and installation guidance to ensure the equipment arrives safely and is put into use.

Features

Specifications

| Operating Environment | 15ºC to 30ºC; Maximum Relative Humidity 80%, No Condensation |

| Ignition Method | Cotton Thread or Ignition Wire |

| Temperature Resolution | 0.0001℃ |

| Test Mode | Isoperibol |

| Test Time | Conventional Method <15min, Rapid Method <10min |

| Calorific Value Testing Range | ≤34000J |

| Calorific Precision | ≤0.10% |

| Calorific Fluctuation | ≤0.20% |

| Maximum Oxygen Bomb Pressure | 240bar |

| Bomb Material | Stainless steel, Hastelloy (corrosion-resistant) |

| Data Storage Capacity | ≥10,000 entries |

Applications

Videos

Product

Automatic oxygen bomb calorimeter

ATC 300A