Battery Calorimeter

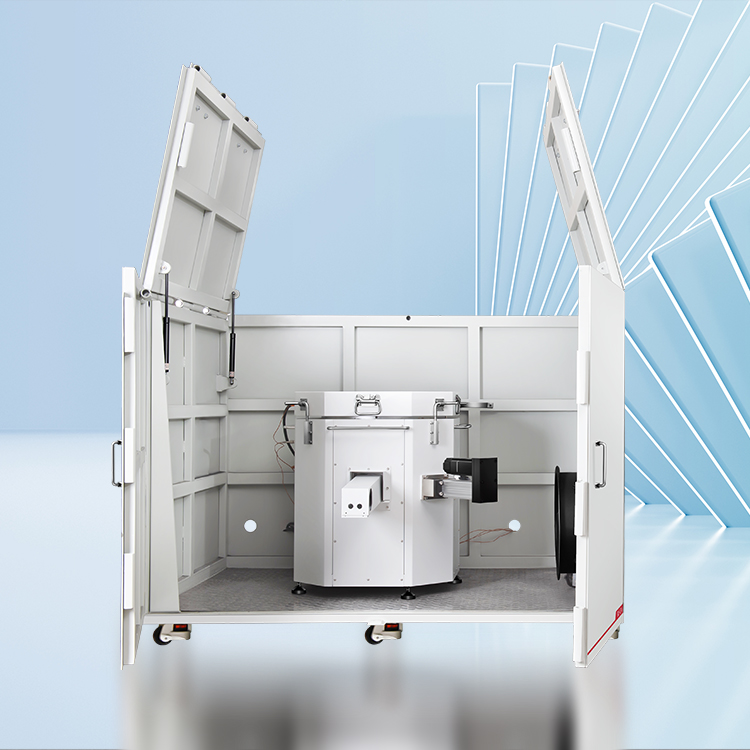

The Large Battery Adiabatic Calorimeter is designed to study thermal runaway and thermal propagation mechanisms in large-format battery cells, such as prismatic and pouch cells, as well as small modules. By tracking temperature changes in the battery and dynamically adjusting the calorimetric chamber temperature, the calorimeter eliminates the temperature difference between the battery and the chamber, achieving adiabatic conditions.

Test Parameters

Thermal Runaway Onset Temperature, Maximum Rate of Temperature Rise, Adiabatic Temperature Rise, Specific Heat Capacity, etc.

Applicable Fields

Battery Pack, Battery Cell

Keywords

Battery Cell Testing, Lithium-ion Battery Testing, Battery Performance Testing

Description

Product Uses

The Large Battery Adiabatic Calorimeter is an essential instrument for evaluating the thermal stability and thermokinetic parameters of lithium-ion batteries during thermal runaway. It effectively measures key parameters such as the onset temperature of self-exothermic reaction (Tonset), the onset temperature of thermal runaway (TTR), the maximum temperature during thermal runaway (Tmax), the depressurization temperature (Tv), the maximum temperature rise rate ((dT/dt)max), and the incubation time of thermal runaway (∆t). These parameters serve as design inputs for battery thermal management systems, aiding researchers in determining the safety boundaries and potential hazards of lithium-ion batteries, and enabling the prevention and early warning of thermal runaway.

- Professional Structural Enhancement: While reducing the furnace’s own heat capacity, it ensures good thermal uniformity within the furnace. This allows for higher temperature rise rates and stability under the same heating power.

- High-Power Element Heating: Utilizing heating elements and their extended functions further enhances the instrument’s heating performance, ensuring efficient temperature control of the furnace.

- Intelligent Algorithm Upgrade: Integrating control strategies such as Smith predictor, adaptive parameter adjustment, and fuzzy PID regulation to achieve high-precision uniform temperature rise control of the furnace, ensuring the efficiency and stability of temperature control.

Precautions

- Sample Preparation: Ensure the battery surface is clean and free from short-circuit risks.

- Safety Protection: Check the gas exhaust system before testing to prevent the accumulation of harmful gases.

- Environmental Requirements: The testing area should have good ventilation and fire prevention measures.

- Data Recording: Continuously monitor data during the test to prevent any anomalies.

- Equipment Calibration: Regularly calibrate temperature sensors and heat flow meters to ensure measurement accuracy.

Service and Support

- Technical Support: Offers remote and on-site technical support.

- Regular Maintenance: Provides equipment calibration and maintenance services.

- Training Services: Offers user training to ensure proper operation.

- Software Upgrade: Supports remote upgrades to optimize data analysis capabilities.

Features

Specifications

| Adiabatic Furnace Dimensions | Diameter 420mm, Depth 520mm |

| Self-exothermic Detection Sensitivity | 0.02℃/min to 0.05℃/min |

| Temperature Difference between Furnace and Sample in Constant Temperature | ≤0.5℃ |

| Temperature Control Range | RT to 300℃ |

| Temperature Tracking Rate | 0.02℃/min to 13℃/min |

| Sealed Canister Pressure Range | 0 to 2MPa |

| Maximum Needle Travel | Setting through software |

| Charge and Discharge Column Overcurrent Capability | -500A to 500A |

Applications

Videos

Instruction

Large Battery Adiabatic Calorimeter

BAC-420AE