Bomb Calorimeter Price

The calorimeter complies with international standards such as ASTM and GB/T, ensuring the reliability, accuracy, and repeatability of results. Additionally, it achieves an excellent balance between performance and price, offering an attractive cost-performance ratio.

Test Parameters

Calorific Value

Applicable Fields

Coal, Metallurgy, Construction, Petrochemical

Keywords

Bomb Calorimeter, Laboratory Calorimeter, Calorimeter Instrument, Bombenkalorimeter

Description

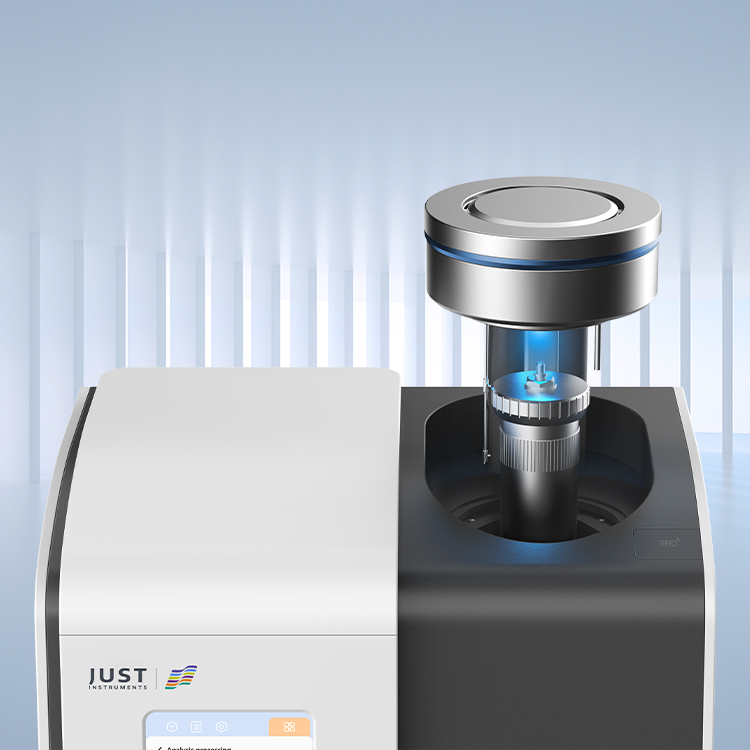

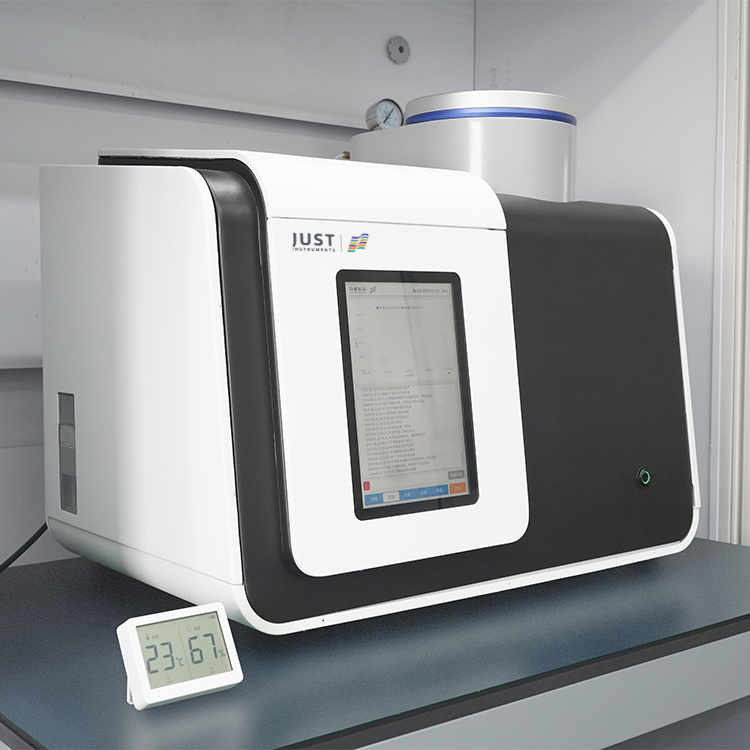

The bomb calorimeter is a high-precision instrument specifically designed for determining the calorific value of solid and liquid fuels, with a testing time of less than ten minutes (rapid method), delivering accurate and reliable results. Featuring advanced automation capabilities, robust construction, user-friendly design, and straightforward operation procedures, it serves as an essential tool for laboratories, research centers, and industrial applications.

Precautions

-

Proper Use of Oxygen: Use certified oxygen cylinders only.

-

Accurate Weighing: Precisely measure the sample mass to ensure the accuracy of experimental results.

-

Avoid Overloading: Do not exceed the recommended sample amount to ensure complete combustion and stay within the instrument’s pressure tolerance.

-

Environmental Conditions: Operate the equipment within the recommended temperature and humidity ranges to ensure stable performance.

-

Regular Calibration: Calibrate the instrument using benzoic acid as per the manual to maintain measurement accuracy.

-

Routine Maintenance: Regularly inspect valves, seals, and other components to prevent wear and tear from affecting performance.

-

Safe Operation: Strictly follow the user manual and wear appropriate protective equipment.

Sample Requirements

-

Type: Solid or liquid fuels.

-

Weight: 0.5–1.5 g per test (depending on sample type).

-

Preparation: Ensure the sample is homogeneous, dry, and free from contamination.

-

Storage: Store samples in sealed containers to avoid contamination or moisture absorption.

Ordering Guide

-

Product Customization: Select additional accessories as needed, such as Hastelloy oxygen bombs, benzoic acid, or crucibles.

-

Power Configuration: Confirm the local power supply requirements (220V ±10%, 50Hz).

-

Installation Support: Request installation and user training services if required.

-

Warranty Options: Choose extended warranty or maintenance plans for long-term support.

-

Logistics Information: Provide detailed delivery addresses and customs clearance requirements to ensure smooth delivery.

Features

Specifications

| Operating Environment | 15ºC to 30ºC; Maximum Relative Humidity 80%, No Condensation |

| Ignition Method | Cotton Thread or Ignition Wire |

| Temperature Resolution | 0.0001℃ |

| Test Mode | Isoperibol |

| Test Time | Conventional Method <15min, Rapid Method <10min |

| Calorific Value Testing Range | ≤34000J |

| Calorific Precision | ≤0.10% |

| Calorific Fluctuation | ≤0.20% |

| Maximum Oxygen Bomb Pressure | 240bar |

| Bomb Material | Stainless steel, Hastelloy (corrosion-resistant) |

| Data Storage Capacity | ≥10,000 entries |

Applications

Videos

Product

Automatic oxygen bomb calorimeter

ATC 300A