Research on the Relationship between the Thermal Conductivity of Prismatic Lithium-ion Batteries and State of Charge (SOC)

Lithium-ion batteries, as a type of rechargeable power source, are widely used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) due to their high power density, low self-discharge rate, and long lifespan. However, lithium-ion batteries also have their limitations. The significant amount of heat generated during the charging and discharging processes can lead to a substantial increase in battery temperature. Particularly under high charge-discharge rates and high operating temperatures, this can result in rapid capacity degradation and even trigger thermal runaway of the battery. Therefore, various types of battery thermal management systems (BTMS) have been extensively researched to maintain the battery within an optimal operating temperature range of 25℃ to 40℃ and to keep the maximum temperature difference within the battery pack below 5℃. It is important to note that the thermal conductivity of the battery is a crucial thermophysical property required for the design of BTMS, influencing both the structural design of the system and the temperature control strategies.

Currently, the testing methods for the thermal conductivity of prismatic batteries are mainly divided into two categories: indirect calculation and direct measurement. Indirect calculation methods include simulation methods and thermal network modeling, among others. These methods simplify the battery into a more easily calculable model and calculate the equivalent thermal conductivity of the battery based on the thermophysical properties of its components and materials [1]. However, the universality and accuracy of the calculation models are often compromised due to the complexity of the battery’s internal structure, changes in system boundary conditions, and variations in battery material characteristics. Therefore, testing the thermal conductivity of batteries using appropriate instruments is a more direct and effective approach.

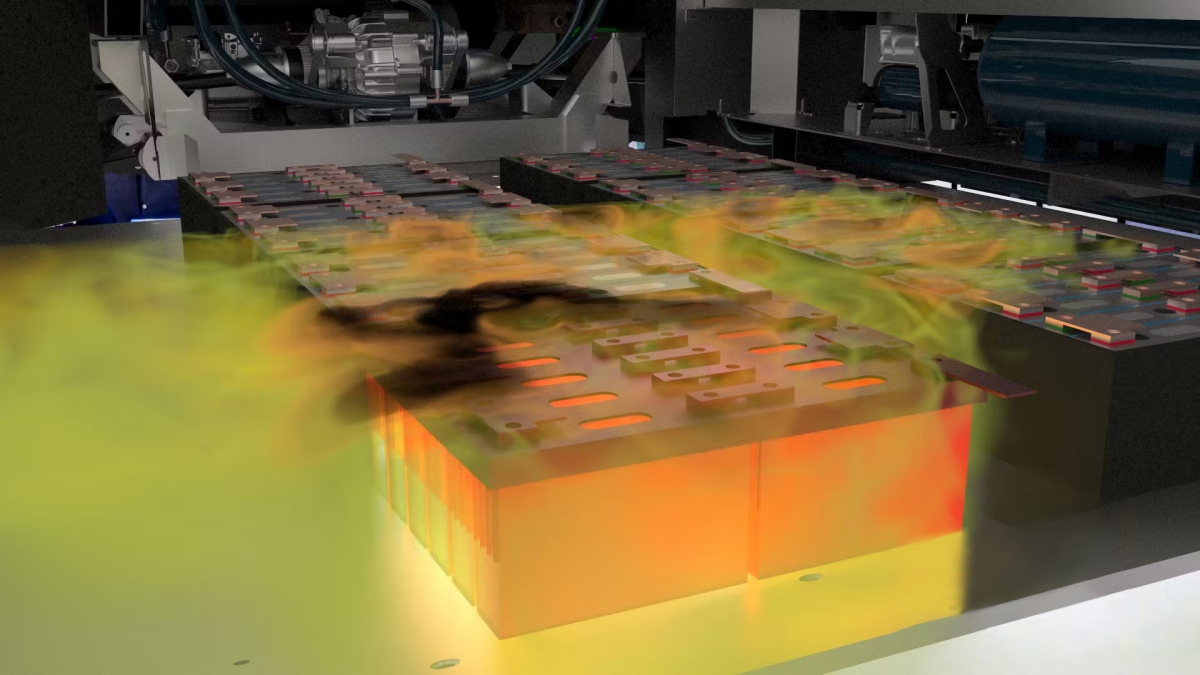

This paper introduces the Dual-state Thermal Parameter Tester from Zeal Instrument, which tests the thermal conductivity of a 280Ah lithium iron phosphate prismatic lithium-ion battery without damaging the battery (as shown in Figure 1). The test obtains the in-plane and through-plane thermal conductivity parameters of the battery at different States of Charge (SOC). The results are helpful for researchers to validate battery thermal models, optimize battery safety design, and enhance the performance of BTMS systems.

Figure 1: 01# Battery with Blackbody Paint (Left) and Installation Diagram (Right)

Experimental Results

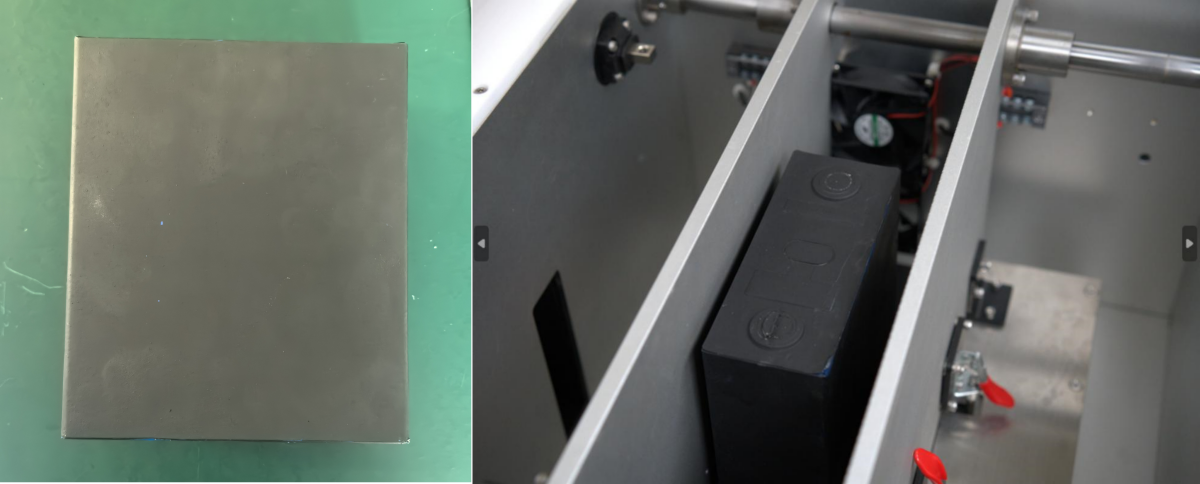

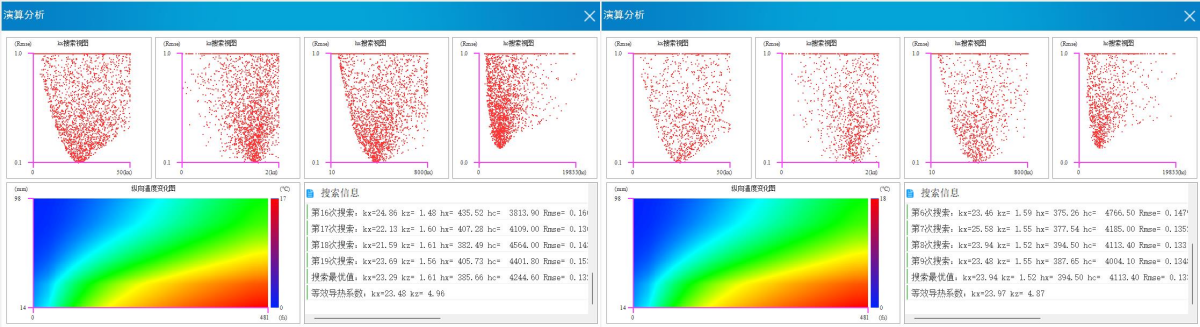

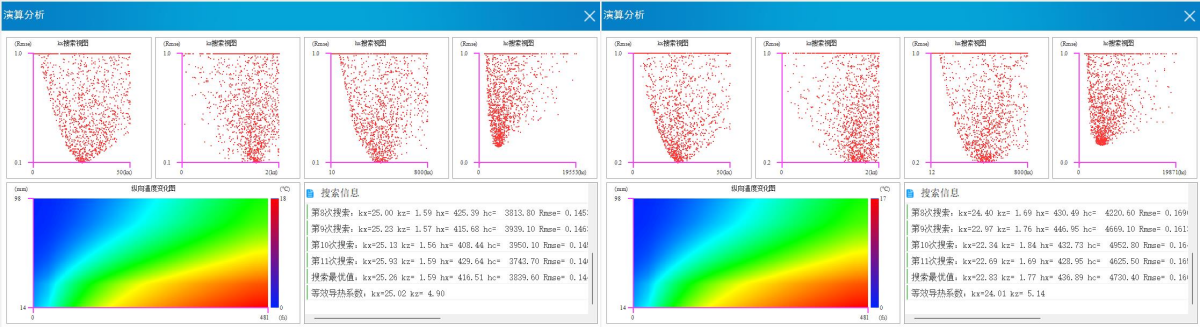

Figure 2: Error Function of Inverse Calculation Parameters for 01# (Left) and 02# (Right) Batteries at 0% SOC

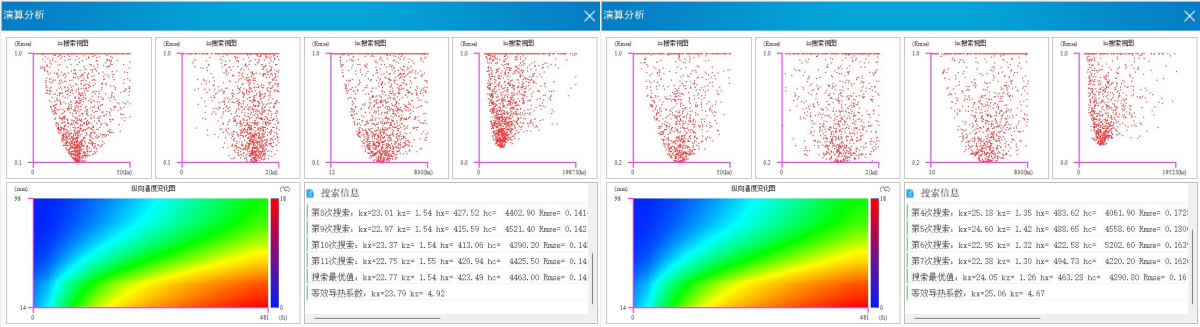

Figure 3: Error Function of Inverse Calculation Parameters for 01# (Left) and 02# (Right) Batteries at 25% SOC

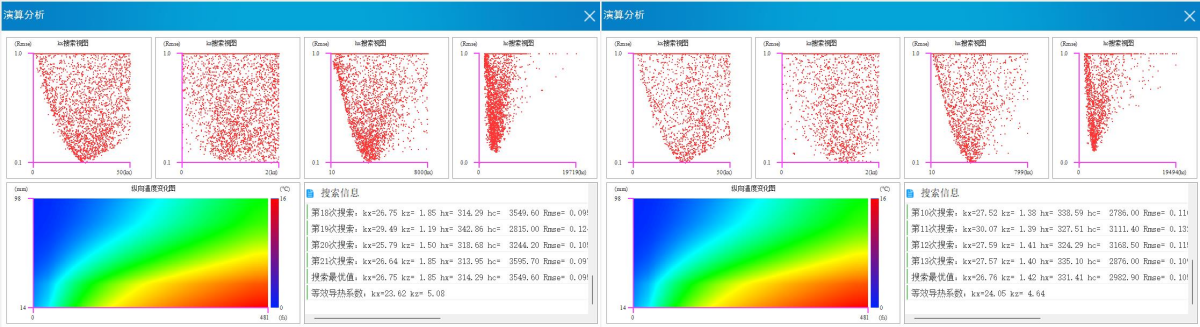

Figure 4: Error Function of Inverse Calculation Parameters for 01# (Left) and 02# (Right) Batteries at 50% SOC

Figure 5: Error Function of Inverse Calculation Parameters for 01# (Left) and 02# (Right) Batteries at 100% SOC

Table 1: Summary of Thermal Parameter Test Results

|

Sample Number |

SOC/% |

In-plane Thermal Conductivity of Laminates kx |

Through-plane Thermal Conductivity of Laminates kz |

Heat Transfer Coefficient between Laminates and Casing (Large Surface) hx |

Heat Transfer Coefficient between Laminates and Casing (Cooling Surface) hc |

Overall Equivalent In-plane Thermal Conductivity kinUni |

Overall Equivalent Through-plane Thermal Conductivity kcrUni |

| 01# | 0 | 22.77 | 1.54 | 423.49 | 4463.00 | 23.79 | 4.92 |

| 02# | 0 | 24.05 | 1.26 | 463.28 | 4290.80 | 25.06 | 4.67 |

| 01# | 25 | 26.75 | 1.85 | 314.29 | 3549.60 | 23.62 | 5.08 |

| 02# | 25 | 26.76 | 1.42 | 331.41 | 2982.90 | 24.05 | 4.64 |

| 01# | 50 | 23.29 | 1.61 | 385.66 | 4244.60 | 23.48 | 4.96 |

| 02# | 50 | 23.94 | 1.52 | 394.50 | 4113.40 | 23.97 | 4.87 |

| 01# | 100 | 25.26 | 1.59 | 416.51 | 3839.60 | 25.02 | 4.90 |

| 02# | 100 | 22.83 | 1.77 | 436.89 | 4730.40 | 24.01 | 5.14 |

Note: 1. The overall in-plane thermal conductivity equivalent condition is: battery heating, with bottom liquid cooling; 2. The overall through-plane thermal conductivity equivalent condition is: battery heating; 3. The unit of thermal conductivity is W/(m·K), and the unit of heat transfer coefficient is W/(m²·K).

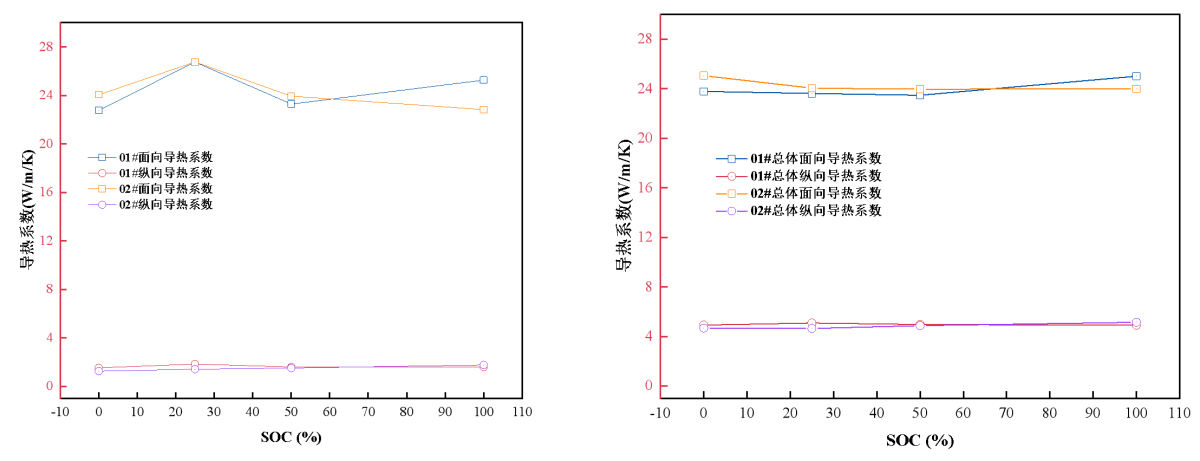

Figure 6: Variation of Laminated Anisotropic Thermal Conductivity (Left) and Cell Equivalent Thermal Conductivity (Right) with SOC

As previously introduced, the TCA 2SC-080 Dual-state Thermal Parameter Tester calculates the in-plane and through-plane thermal conductivities of the internal laminated structure, the heat transfer coefficients between the laminated structure and the large surface casing, and between the laminated structure and the bottom (cooling surface) casing of the battery cell through infrared thermography and heat transfer model inversion in a single test. It also computes the overall equivalent in-plane and through-plane thermal conductivities of the battery cell.

From Table 1 and Figure 6, it can be observed that the in-plane thermal conductivity of the internal laminated structure of the 280Ah lithium iron phosphate battery ranges from 22 to 27 W/(m·K), and the through-plane thermal conductivity ranges from 1.2 to 1.8 W/(m·K). The equivalent in-plane thermal conductivity of the battery cell is approximately 23 to 25 W/(m·K), and the equivalent through-plane thermal conductivity ranges from 4.6 to 5.2 W/(m·K). Additionally, there is no significant trend change in the thermal conductivity of the lithium iron phosphate prismatic battery at different States of Charge (SOC), which is consistent with relevant literature [2].

Conclusion

This paper utilized the TCA 2SC-080 Dual-state Thermal Parameter Tester from Hangzhou Zeal Instrument Co., Ltd. to perform non-destructive testing of the thermal conductivity of the 280Ah lithium iron phosphate prismatic lithium-ion battery, obtaining the in-plane and through-plane thermal conductivity and other thermophysical parameters at different SOCs. The results indicate that there is no significant correlation between the thermal conductivity of this type of prismatic lithium iron phosphate battery and its SOC. These findings are beneficial for researchers to validate battery thermal models and optimize battery safety design and BTMS system performance.

References

[1] Cui Xifeng, Zhang Hongliang, Gong Yang, et al. Thermophysical properties of square hard-shell lithium-ion power batteries [J]. Nonferrous Metals, 2019, 29(12): 2747-2756. DOI: 10.19476/j.ysxb.1004.0609.2019.12.07

[2] Kovachev G, Astner A, Gstrein G, et al. Thermal conductivity in aged Li-ion cells under various compression conditions and state-of-charge[J]. Batteries, 2021, 7(3): 42.