Characteristic Study in Thermal Runaway Testing: Large Capacity High Nickel Lithium-ion Batteries

Overview – Thermal Runaway

Lithium-ion batteries have become indispensable in powering modern technology, from smartphones to electric vehicles. Among the various types of lithium-ion batteries, high-nickel compositions are gaining prominence due to their ability to deliver high capacity, making them ideal for applications requiring extended usage periods.

However, with increased capacity comes the challenge of managing thermal runaway events, which can pose serious safety risks. In this blog post, we delve into the research conducted on thermal runaway characteristics in high-nickel lithium-ion batteries with large capacities using a Large Battery Adiabatic Calorimeter(BAC-420A).

Introduction – Thermal Runaway

The evolution of lithium-ion batteries has been marked by continuous advancements in chemistry and design to enhance energy density, lifespan, and safety. High-nickel compositions, such as NCM (Nickel-Cobalt-Manganese) 811, have emerged as promising candidates for high-capacity applications. These batteries offer higher energy densities and lower costs compared to their predecessors, making them increasingly prevalent in electric vehicles and energy storage systems. However, the quest for higher capacity has also brought about challenges related to thermal management and safety.

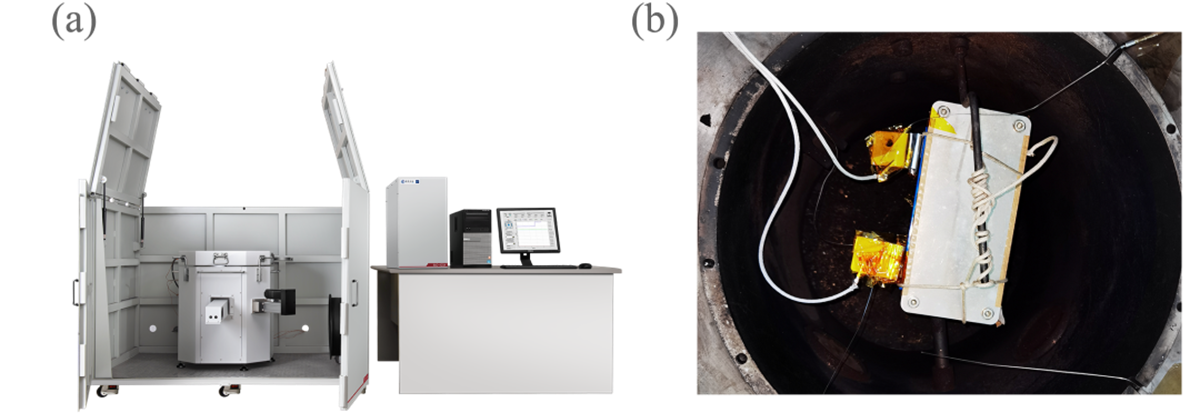

Previous research on thermal runaway in lithium-ion batteries has primarily focused on smaller cell sizes. The lack of data on thermal runaway characteristics in large-capacity high-nickel batteries has been a significant gap in the field. Traditional adiabatic calorimeters were not equipped to handle the safety risks associated with testing such batteries. Zeal Instrumentssupplied the Large Battery Adiabatic Calorimeter(BAC-420A) used in the study. This specialized equipment was designed to safely test large-capacity high-nickel lithium-ion batteries.The calorimeter featured a spring-lock mechanism in its top cover and furnace body, enhancing its ability to withstand pressure build-up during thermal runaway events.

Experimental Procedure

- The study utilized 190Ah NCM 811 pouch cells at 100% state of charge (SOC).

- Instruments: BAC-420A calorimeter, battery cycling equipment, TP-700 multi-channel tester;

- Environmental Parameters: The experiments were conducted at a temperature of 28°C;

- Sampling Rate:1-100Hz;

- Controlled Heating Mode: The HWS-R (Heat-Wait-Search-Reaction) mode was employed;

- Threshold Detection: Thermal runaway was detected based on a self-heating rate threshold of 0.02°C/min;

- Temperature Measurement Points: Thermocouples were placed at various locations on the cell to monitor temperature changes.

Figure 1 (a) BAC-420A large battery adiabatic calorimeter and (b) battery samples installation diagram

Results

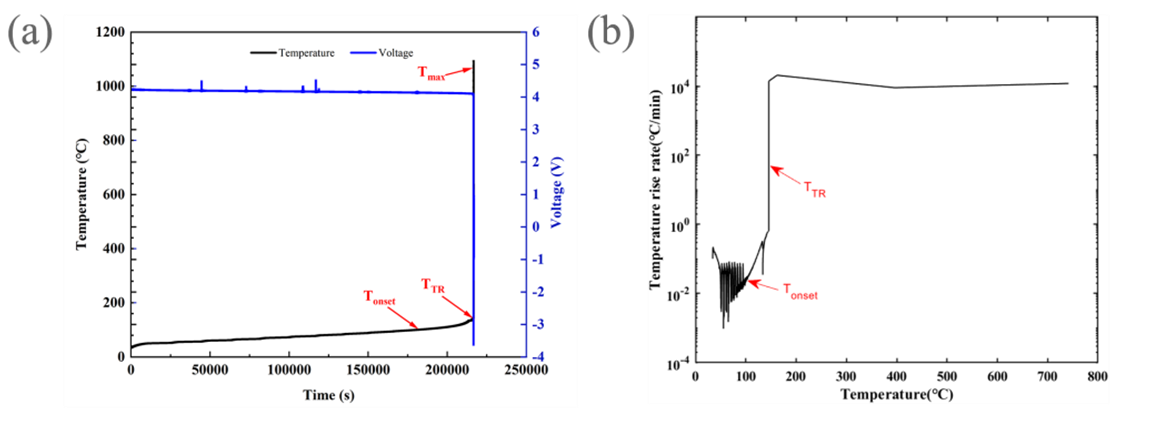

The experiments conducted with the Large Battery Adiabatic Calorimeter(BAC-420A) revealed significant insights into the thermal runaway behavior of high-capacity high-nickel lithium-ion batteries. The adiabatic thermal runaway curve depicted in Figure 2(a) illustrates the temperature rise and voltage-time relationship during the thermal runaway event. The curve demonstrates a rapid increase in temperature and voltage, indicative of high energy release rates.

Figure 2 190Ah battery thermal runaway(a) temperature rise – voltage curves(b) temperature rise rate-temperature curve

Furthermore, the temperature-rate curve (Figure 2(b)) highlights the steep rise in temperature, with a maximum temperature (Tmax) reaching approximately 1100°C and a maximum temperature rise rate exceeding 10000°C/min. These findings surpass the data observed in previous studies on lithium-ion batteries with different chemistries, such as lithium iron phosphate and medium to low-nickel NCM batteries.

|

|

| Figure 3 190Ah battery thermal runaway process explosion-proof box (a) external and (b) internal video screen | |

Video monitoring during the thermal runaway process provided valuable insights into the violent phenomena associated with high-capacity high-nickel lithium-ion batteries. Intense smoke and flames were observed erupting from the battery cell during the thermal runaway event. Additionally, on-site observations revealed that while the calorimeter remained undamaged, the explosion of the battery cell generated powerful airflow capable of causing significant damage to objects up to 5 meters away.

These observations underscore the importance of ensuring sufficient venting area in the laboratory when conducting tests on large-capacity high-nickel batteries to mitigate safety risks.

Conclusion

The study conducted using the Large Battery Adiabatic Calorimeter(BAC-420A) sheds light on the thermal runaway characteristics of high-capacity high-nickel lithium-ion batteries. By filling a crucial gap in research, this study contributes to the advancement of battery safety and management practices, particularly in applications where large-capacity batteries are employed. The findings underscore the importance of specialized equipment and rigorous testing protocols in ensuring the safety and reliability of lithium-ion battery systems.

Reference

[1] 2022 New Energy Vehicle Promotion Subsidy Program [EB/OL]. www.gov.cn,2021-12-31.

[2] Analysis of the development trend of power battery range for new energy passenger cars [DB/OL]. www.autoinfo.org.cn,2021-06-18.