Runaway Chemical Reactions: Causes and Prevention

Runaway chemical reactions are an inherent risk in the chemical industry. When these reactions occur, they can lead to explosions, fires, and other catastrophic events that can cause property damage, injuries, and even death. It is important for those working in the industry to understand what runaway reactions are, how they occur, and what steps can be taken to prevent them.

A runaway reaction is a chemical reaction that becomes uncontrollable and self-propagating. This can occur when the heat generated by the reaction is not effectively dissipated, leading to a rise in temperature that further accelerates the reaction. As the reaction continues to produce heat, the temperature can rise rapidly, leading to a dangerous situation.

There are a number of factors that can contribute to a runaway reaction, including improper mixing of reactants, insufficient cooling, and equipment failure. It is important for those working in the industry to be aware of these factors and to take steps to minimize the risk of a runaway reaction occurring. By understanding the causes of runaway reactions and taking appropriate precautions, it is possible to reduce the risk of accidents and ensure the safety of those working in the chemical industry.

Fundamentals of Chemical Reactions

Chemical reactions are the transformation of one or more substances into new substances with different chemical and physical properties. These reactions can be exothermic or endothermic, meaning they either release or absorb energy. Understanding the thermodynamics and kinetics of chemical reactions is crucial to controlling them and preventing runaway reactions.

Thermodynamics of Runaway Reactions

Thermodynamics is the study of energy and its transformations in chemical systems. The thermodynamics of a chemical reaction can predict whether it will occur spontaneously or not. The Gibbs free energy change (ΔG) is a measure of the spontaneity of a reaction. If ΔG is negative, the reaction is spontaneous and will release energy. If ΔG is positive, the reaction is non-spontaneous and will require energy input to occur.

In the case of a runaway reaction, the reaction becomes exothermic and releases more energy than it consumes. This results in an increase in temperature, which can lead to a positive feedback loop that further increases the reaction rate and temperature. Understanding the thermodynamics of a reaction is crucial to preventing runaway reactions by designing systems that can dissipate excess heat and prevent pressure buildup.

Kinetics and Reaction Rates

Kinetics is the study of the rate and mechanism of chemical reactions. The rate of a reaction is determined by the activation energy, which is the minimum amount of energy required for a reaction to occur. The reaction rate can be increased by increasing the temperature, pressure, or concentration of reactants.

In the case of a runaway reaction, the reaction rate increases uncontrollably due to a positive feedback loop. This can lead to a rapid increase in temperature and pressure, which can cause an explosion or other hazardous conditions. Understanding the kinetics of a reaction is crucial to preventing runaway reactions by designing systems that can control the reaction rate and prevent positive feedback loops.

In summary, understanding the thermodynamics and kinetics of chemical reactions is crucial to preventing runaway reactions by designing systems that can dissipate excess heat, prevent pressure buildup, and control the reaction rate.

Identification of Runaway Reactions

Predictive Methods

Predictive methods involve the use of mathematical models to predict the behavior of chemical reactions under different conditions. These models can be used to identify potential runaway reactions by analyzing the rate of heat generation and the rate of heat removal.

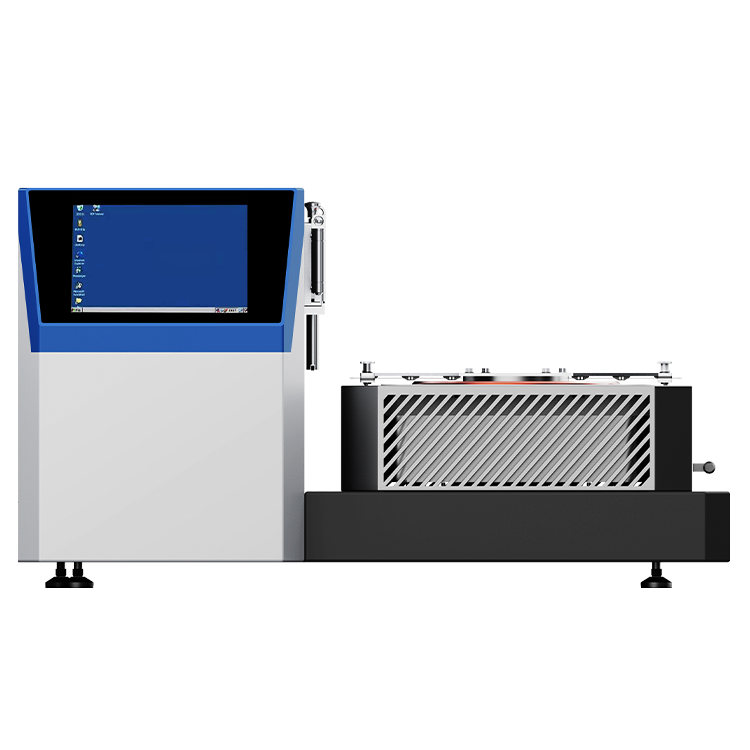

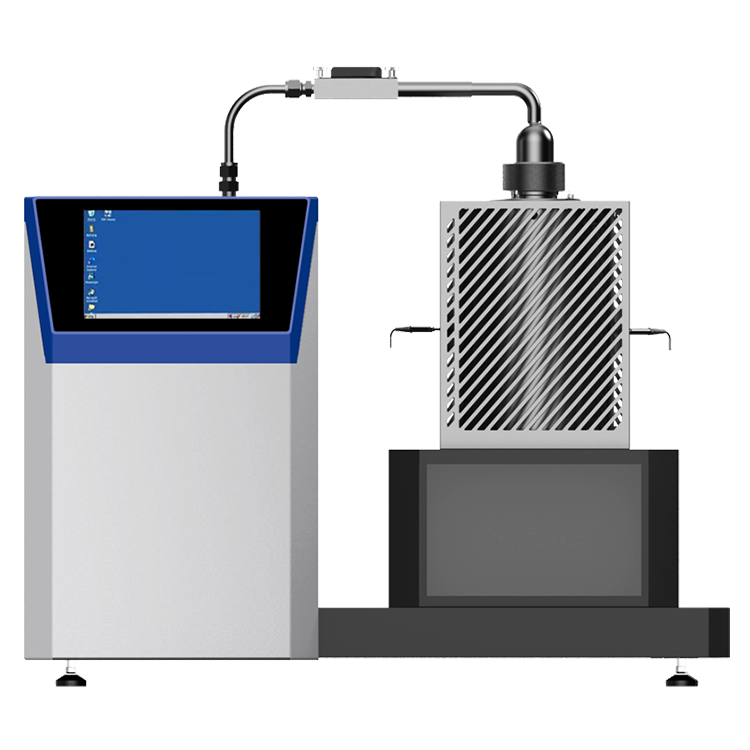

One common predictive method is adiabatic calorimetry, which involves measuring the heat generated by a reaction and the rate at which the heat is removed. This information can be used to predict the temperature and pressure changes that would occur if the reaction were to run away.

Another predictive method is reaction calorimetry, which involves measuring the heat generated by a reaction as it occurs. This information can be used to predict the maximum temperature that the reaction will reach and the rate at which the temperature will increase.

Diagnostic Indicators

Diagnostic indicators are physical or chemical changes that occur when a reaction starts to run away. These changes can be used to identify a potential runaway reaction before it becomes unmanageable.

One diagnostic indicator is an increase in temperature or pressure. If the temperature or pressure of a reaction increases rapidly, it may be an indication that the reaction is starting to run away.

Another diagnostic indicator is the production of gas. If a reaction produces gas rapidly, it may be an indication that the reaction is starting to run away.

It is important to note that these diagnostic indicators are not foolproof and may not always be present in a runaway reaction. Therefore, it is important to use a combination of predictive methods and diagnostic indicators to identify potential runaway reactions and take appropriate measures to prevent them from occurring.

Risk Management

When dealing with chemical reactions, it is crucial to have a well-thought-out risk management plan in place. This plan should include both preventive measures and emergency contingency planning to ensure that any potential risks are minimized and that you are prepared to handle any emergencies that may arise.

Preventive Measures

Preventive measures are the first line of defense against runaway chemical reactions. Here are some important preventive measures to consider:

Inherently safer design: Designing a chemical process or reactor with inherently safer features can reduce the likelihood of a runaway reaction. This can include using less hazardous materials, designing a more stable reaction pathway, or using automatic controls to prevent temperature or pressure spikes.

Risk assessment: Conducting a thorough risk assessment can help identify potential hazards and determine the likelihood and consequences of a runaway reaction. This can help inform the design of the process or reactor and identify any necessary safety measures.

Training and safety procedures: Proper training and safety procedures are critical to preventing accidents. All employees should be trained on the potential hazards of the chemicals they work with and the safety procedures that must be followed to prevent accidents.

Emergency Contingency Planning

Despite your best efforts to prevent a runaway reaction, emergencies can still occur. Here are some important emergency contingency planning measures to consider:

Emergency response plan: Having an emergency response plan in place can help ensure that everyone knows what to do in the event of an emergency. This plan should include procedures for evacuating the area, shutting down the reactor, and notifying emergency services.

Emergency equipment: Having the right emergency equipment on hand can help mitigate the consequences of a runaway reaction. This can include fire suppression systems, emergency venting systems, and personal protective equipment.

Regular drills and training: Regular drills and training can help ensure that everyone knows how to respond in an emergency. This can include practicing emergency shutdown procedures, evacuations, and using emergency equipment.

By implementing these preventive measures and emergency contingency planning measures, you can help minimize the risks associated with runaway chemical reactions and ensure that you are prepared to handle any emergencies that may arise.

Case Studies of Runaway Reactions

Runaway chemical reactions can have catastrophic consequences. Several incidents have occurred in the past that have resulted in loss of life, injuries, and damage to property. Here are a few case studies of runaway reactions:

T2 Laboratories Explosion

The T2 Laboratories explosion occurred in December 2007 and resulted in four fatalities and 32 injuries. The incident investigation conducted by the U.S. Chemical Safety Board (CSB) identified the root cause as a failure to recognize the runaway reaction hazard associated with the chemical being produced. The reaction was exothermic and produced a large amount of heat, which caused the temperature and pressure in the reactor to increase rapidly. The reactor was not designed to handle such conditions, and the pressure relief system was inadequate. As a result, the reactor ruptured, causing a massive explosion.

Phenol-Formaldehyde Runaway Reaction

A runaway reaction occurred during the production of phenol-formaldehyde resin in a batch reactor. The reaction was initiated by the addition of formaldehyde, which caused the temperature to increase rapidly. The cooling system was unable to handle the heat generated by the reaction, and the temperature continued to rise. The reaction became exothermic and resulted in a thermal runaway. The reactor was not designed to handle such conditions, and the pressure relief system was inadequate. The pressure in the reactor increased rapidly, causing the reactor to rupture and resulting in a massive explosion.

MEKPO Decomposition

A runaway reaction occurred during the decomposition of MEKPO in a hybrid system, where the generation of non-condensable gas and vaporization of solvents occurred at the same time. The vent sizing calculation for the hybrid system was adopted as a gassy system, without accounting for vaporization. The reaction became exothermic and resulted in a thermal runaway. The reactor was not designed to handle such conditions, and the pressure relief system was inadequate. The pressure in the reactor increased rapidly, causing the reactor to rupture and resulting in a massive explosion.

These case studies highlight the importance of recognizing the hazards associated with chemical reactions and designing reactors that can handle such conditions. It is essential to have adequate pressure relief systems in place to prevent catastrophic incidents.

Regulatory and Safety Guidelines

When working with chemicals, it is crucial to follow regulatory and safety guidelines to prevent runaway reactions and ensure the safety of personnel and the environment. The following are some guidelines that you should follow:

Hazard Communication

The Occupational Safety and Health Administration (OSHA) requires that all hazardous chemicals be properly labeled and that workers be trained on the hazards associated with those chemicals. You should always read the label and the Safety Data Sheet (SDS) before working with a chemical. The SDS provides information on the hazards associated with the chemical, including its physical and chemical properties, health hazards, and emergency procedures.

Process Safety Management

The OSHA Process Safety Management (PSM) standard requires employers to develop and implement a plan to manage the hazards associated with processes involving highly hazardous chemicals. The plan should include procedures for identifying and evaluating hazards, implementing controls, and training workers. It should also include procedures for managing changes to the process and for conducting incident investigations.

Emergency Planning and Response

In the event of a chemical release or other emergency, it is essential to have a plan in place for responding quickly and effectively. OSHA requires that employers develop and implement an Emergency Action Plan (EAP) that includes procedures for notifying personnel, evacuating the area, and providing medical treatment. You should also have procedures in place for containing the release and preventing it from spreading to other areas.

Engineering Controls

Engineering controls, such as ventilation systems and pressure relief devices, can help prevent runaway reactions by controlling the release of hazardous chemicals. You should ensure that these controls are properly designed, installed, and maintained to ensure their effectiveness. It is also important to regularly inspect and test these systems to ensure that they are functioning properly.

By following these guidelines, you can help prevent runaway reactions and ensure the safety of personnel and the environment. Remember to always follow the manufacturer’s instructions and seek guidance from a qualified professional if you have any questions or concerns.