What is Vapor Pressure Tester and Its Importance in Liquid Testing

Have you ever wondered how scientists measure the evaporation tendency of volatile liquids or how to evaluate the risks of vapor buildup in pipelines? The answer lies in the concept of saturated vapor pressure, a key parameter that influences how liquids behave under varying conditions.

At its core, saturated vapor pressure refers to the pressure exerted by a vapor when it is in equilibrium with its liquid phase at a particular temperature. This value indicates how easily a liquid will evaporate. For industries dealing with volatile substances—like oil and chemicals—understanding and measuring vapor pressure is crucial for safety, efficiency, and quality control.

For example, liquids with high saturated vapor pressure are more likely to evaporate, form vapor blocks in pipelines, and experience significant losses during storage and transportation. Furthermore, they can pose inhalation risks to workers, as high vapor pressures lead to higher volatility. This makes vapor pressure testing an essential part of safety assessments in industries like petroleum, chemicals, and pharmaceuticals.

The Need for Accurate Vapor Pressure Testing

Vapor pressure tests are vital for determining how volatile a liquid is and assessing its behavior during storage, transport, and use. For volatile liquids such as gasoline, crude oil, and hydrocarbon mixtures, accurate vapor pressure readings help in evaluating their evaporation potential, minimizing risks related to gas blockages in pipelines, and preventing loss during storage.

Moreover, the saturated vapor pressure of a liquid plays a pivotal role in determining its flammability. Liquids with high vapor pressures release more vapors into the air, which can contribute to hazardous environments, especially in confined spaces. For these reasons, conducting vapor pressure tests on these substances is critical to ensuring that safety standards are met, especially when dealing with flammable and combustible liquids.

In short, the vapor pressure of a liquid is more than just a scientific concept—it’s a measure that can dictate how a substance behaves under varying environmental conditions and how safely it can be handled.

How a Vapor Pressure Tester Works

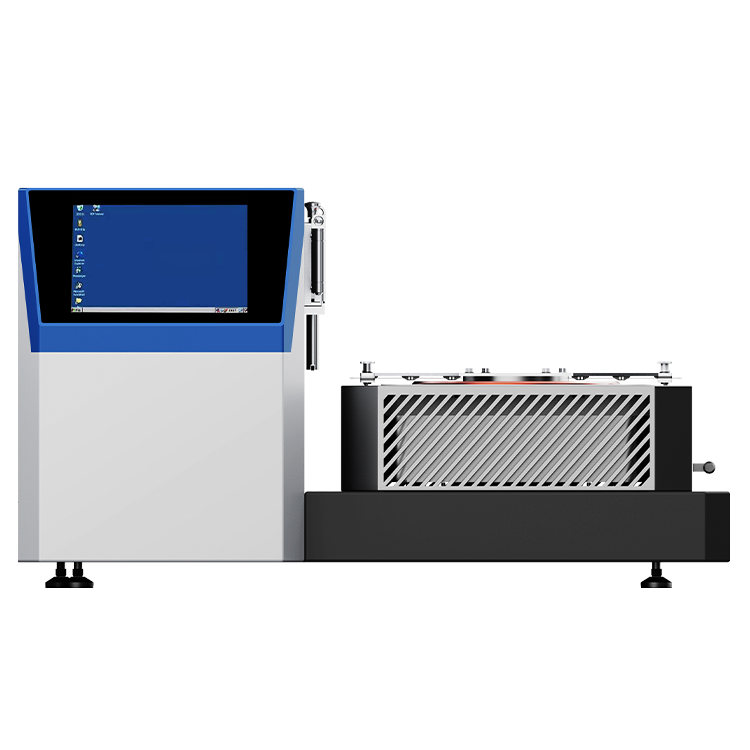

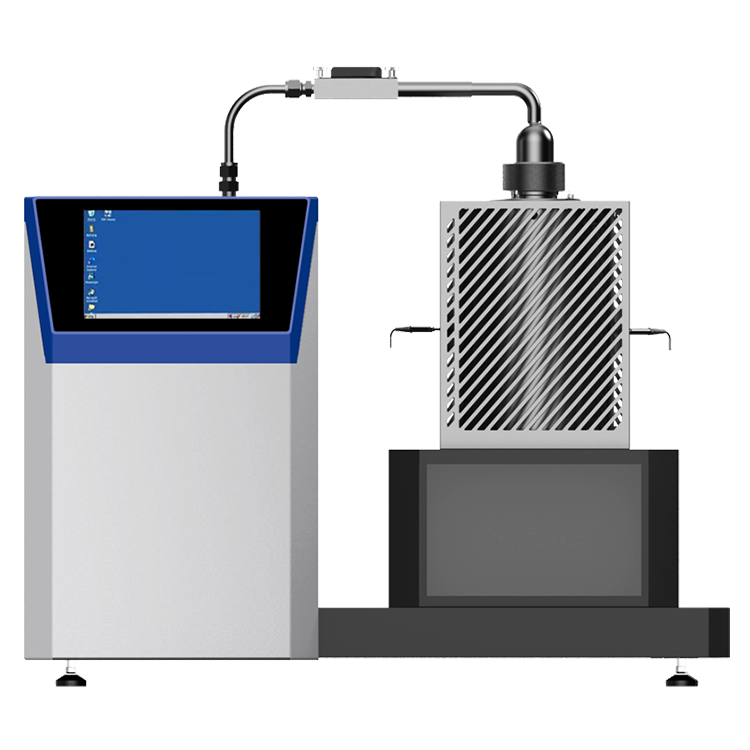

A Vapor Pressure Tester is an advanced tool used to measure the vapor pressure of volatile liquids under controlled conditions. Using an automated process, this device measures the vapor pressure of substances by simulating real-world conditions, such as changes in temperature, and determining the equilibrium pressure between liquid and vapor phases.

The Vapor Pressure Tester provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd. is designed for high-precision testing, using the three-stage expansion method—a globally recognized approach for vapor pressure determination. This method ensures that the measurement of vapor pressure is highly accurate, reliable, and repeatable.

The process begins by placing the sample liquid in a sealed chamber. The temperature of the sample is then adjusted, and the vapor pressure is measured under controlled conditions. The instrument automatically calculates the pressure exerted by the vapor and provides the data for analysis.

Key Features and Specifications

The Vapor Pressure Tester from Hangzhou Zeal Instruments boasts several key features that make it stand out in the industry. Below is a breakdown of its technical specifications:

Operating Environment & Specifications

The Vapor Pressure Tester operates in an ambient environment of 5°C to 40°C with less than 85% RH. Its internal temperature control range is 0–120 °C with a stability of ±0.1 °C. Pressure is detected across a range of 0–1000 kPa with a resolution of 0.01 kPa.

Performance

The instrument demonstrates high precision with a repeatability of ≤0.3 kPa and reproducibility of ≤0.7 kPa (both measured @ 37.8°C, 70 kPa).

Sample & Test Parameters

It requires only 1 mL of sample for testing (approximately 10 mL is needed for rinsing procedures) and supports a gas-to-liquid ratio from 0.02:1 to 4:1.

Interfaces

Multiple connectivity options are provided, including RS232, RJ45, and USB ports, ensuring seamless integration into various laboratory setups.

Advanced Testing Methods and Benefits

The Vapor Pressure Tester from Hangzhou Zeal Instruments leverages advanced technology to provide several notable benefits, making it ideal for industries requiring precise and reliable measurements of volatile liquids:

No Sample Pre-treatment Required

Unlike some vapor pressure testers, which require extensive sample preparation or pre-treatment, this model eliminates these steps, allowing for a one-click operation to initiate tests. This feature not only saves time but also minimizes human error associated with sample handling.

Automated and Error-Free Testing

The device automates the entire testing process, reducing the likelihood of errors introduced by manual operations. This ensures that results are accurate and consistent, providing high-quality data for analysis and decision-making.

Multi-Temperature Testing Capability

The tester can perform tests at multiple temperature points, allowing for flexible settings and automatic generation of temperature-pressure correlation tables. This helps users optimize storage and handling conditions based on temperature variations.

Efficient Cleaning System

The Vapor Pressure Tester features a unique cleaning system that minimizes cross-contamination between samples, improving the accuracy and reliability of results while also increasing testing efficiency.

High-Performance, Low Maintenance

The instrument is designed for high-intensity testing, requiring minimal maintenance. This makes it an ideal choice for laboratories and industries where frequent testing of volatile liquids is required.

User-Friendly Interface

With a 7-inch color LCD touchscreen, the tester offers a user-friendly interface that makes it easy for operators to navigate, monitor tests, and record results. The intuitive design reduces the learning curve, allowing for quick adaptation to the device’s functionalities.

Applications of the Vapor Pressure Tester

The Vapor Pressure Tester plays an essential role in various industries, particularly in the petroleum sector. Some of the key applications include:

1. Petroleum Industry

In the petroleum industry, the Vapor Pressure Tester is used to measure the volatility of products such as gasoline, crude oil, hydrocarbon mixtures, and liquefied petroleum gas (LPG). These tests help to assess the quality of petroleum products, ensuring they meet industry standards for volatility and safety. By determining the vapor pressure, companies can predict how these products will behave during storage, transport, and handling.

2. Chemical and Pharmaceutical Industries

The tester is also essential in the chemical and pharmaceutical industries, where volatile substances are common. Accurate vapor pressure testing helps manufacturers optimize the production, storage, and transportation of chemicals, ensuring that hazardous vapors are properly managed and that the safety of workers and consumers is upheld.

3. Environmental and Safety Testing

For hazardous materials with a high vapor pressure, understanding their volatility is crucial in mitigating environmental and health risks. The Vapor Pressure Tester is an indispensable tool for environmental monitoring and risk assessment, particularly in relation to toxic or flammable liquids.

Conclusion

In summary, the Vapor Pressure Tester provided by Hangzhou Zeal Instruments Science & Technology Co., Ltd. is an advanced, reliable tool for accurately measuring the vapor pressure of volatile liquids. With its user-friendly interface, high precision, and ability to perform automated testing, it is the ideal solution for industries that require consistent and trustworthy measurements of vapor pressure. Whether you’re in the petroleum, chemical, or pharmaceutical industries, this tester ensures that you can evaluate and manage the volatility of liquids safely and efficiently, minimizing risks and enhancing operational effectiveness.